Articles

| Name | Author | |

|---|---|---|

| Using Data to Improve MRO Schedule Management | View article | |

| Compliance – Stronger when tackled together | Geoff Zuber, Director, Holocentric | View article |

| Column How I See IT – 2014 | Michael Wm. Denis | View article |

| Case Study: Stepping up with MRO Software | Rob Vogel, Senior Manager, National Airways Corporation | View article |

| Early Adaptors S1000D | David Boyer, VP of Aerospace Operations, and Tim Larson, Global Product Manager, Flatirons Solutions | View article |

Early Adaptors S1000D

Author: David Boyer, VP of Aerospace Operations, and Tim Larson, Global Product Manager, Flatirons Solutions

Subscribe

Engine manufacturers, say David Boyer, VP of Aerospace Operations, and Tim Larson, Global Product Manager at Flatirons Solutions, take the lead in adopting best practices to support S1000D in a multi-spec world

The focus of this series is the emergence of S1000D as the new information exchange standard for civil aviation and the significant step-change it represents in the way all participants in the civil aviation ecosystem will create, manage, deliver, access, and use information in the future. Along with the gradual adoption of S1000D for new-generation aircraft programs is the ongoing requirement to simultaneously support iSpec 2200 standards for existing programs.

When looking at early adopters, let’s start by specifying what early adoption means in two respects. First, early adoption applies to organizations that are actively creating or working with S1000D content. Early adopters in this sense are the primary original equipment manufacturers (OEMs) – Airbus, Boeing, Bombardier, and other airframe manufacturers – that have identified S1000D as the information standard for their new-generation programs. Early adopters also include suppliers to the primary OEMs who provide components and systems for new-generation aircraft. These OEMs are creators of technical information and, as such, play a role early in the lifecycle of an aircraft and the creation of its technical information.

In contrast, airline operators and their technicians are consumers of technical information. Being further downstream in the introduction of new aircraft, they have not been early adopters actively working with S1000D content. This is largely because airline operators are just now taking delivery of the Boeing 787 Dreamliner, while the Airbus A350 and Bombardier CSeries aircraft are not yet in general production or in active service.

Adoption of S1000D: Engine manufacturers take an early lead

One segment of the civil aviation ecosystem that is actively adopting S1000D as required by the primary OEMs, and tackling head-on the challenges of supporting multiple specifications, is engine manufacturers.

Living in a multi-spec environment

Primary OEMs including Airbus, Boeing, and Bombardier are driving adoption of S1000D across the civil aviation ecosystem by requiring technical information in S1000D for new-generation aircraft. The primary OEMs drive the information standard with which everyone else in the ecosystem has to work. Other OEMs have to produce information for Airbus, Boeing, Bombardier, etc., in both iSpec 2200 and S1000D, and airline operators live in the middle of this multi-spec environment. OEMs and airline operators need to figure out how to accommodate both sets of standards and can adopt best emerging practices to mitigate the cost and complexity of meeting evolving requirements.

These large OEMS have recognized early on that adding a new technical information management system to handle S1000D requirements in parallel to their existing systems is not a sustainable approach. The resulting complexity would be costly, time-consuming, and subject to error. At the same time, they have recognized that cobbling together various applications and databases over time to meet changing requirements is not an alternative or feasible solution either.

Leading engine manufacturers are calling on technical information management specialists with expertise specifically in aerospace and aviation to develop best practices for next-generation systems. The technical information management systems they are developing include key functionalities as discussed in previous articles, including:

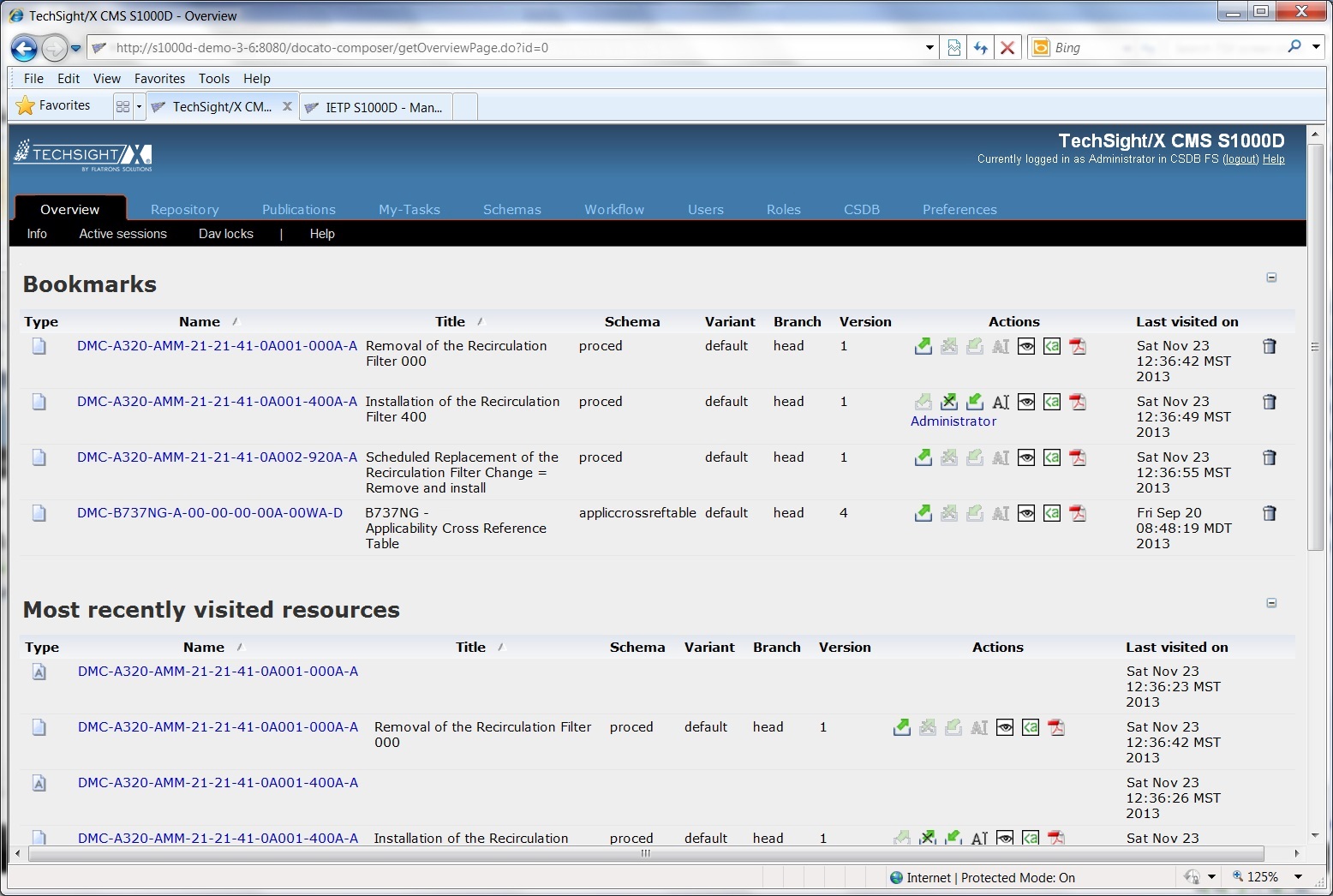

- A single source for reusable content: A solution that provides authors with a ‘one stop shop’ for all content (including XML/SGML, 3D models, graphics, and metadata), which is stored centrally in a Common Source Database (CSDB) for use by multiple sites and business units.

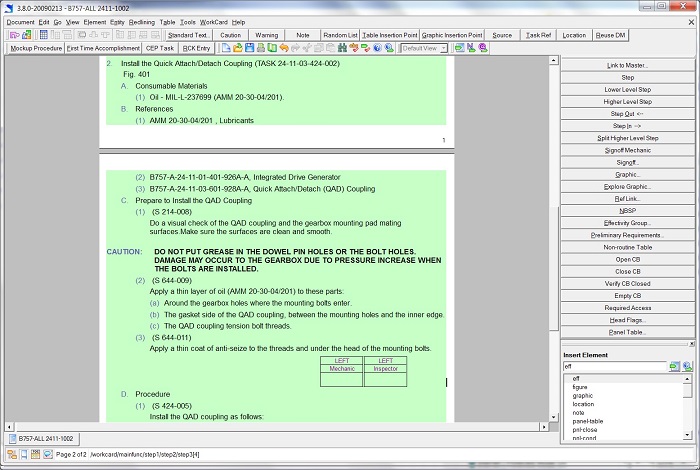

- User-friendly and integrated XML editors: XML editors that reduce the learning curve for authors who are new to XML yet provide the sophisticated XML functionality of traditional editors and that are tightly integrated with other components of the larger system, such as TechSight/X® Editor based on Serna XML Editor from Flatirons Solutions (formerly InfoTrust Group). It offers a word processor-like interface, instant XML validation, and other user-friendly features that make the adoption of XML easier while providing advanced capabilities experienced XML authors expect. Its integration with the TechSight/X CMS (content management system) also facilitates content authoring and editing to increase authors’ productivity and speed up the delivery of up-to-date information to end users.

- On-demand data transformation via publication management: Powerful publication management capabilities automate content transforms for both in-bound technical information (from supplier partners) and out-bound support and maintenance content (for end-customers). This lets OEMs take in, store, and publish out content for both legacy iSpec 2200 and next-generation S1000D fleets — without requiring the OEMs to alter or abandon legacy document type definitions (DTDs). By normalizing content through on-demand data transformation, data can be presented to end users in S1000D or iSpec 2200, PDF, and HTML publishing options, providing the required level of flexibility needed to support a wide array of spec-defined programs and contractual commitments from within a single publishing environment.

- Integration with critical enterprise infrastructure: By providing not only a content management capability but also a powerful workflow engine capable of managing business processes both within and outside the client organization, the technical information management solution is tightly integrated with the client enterprise resource planning (ERP) and reporting infrastructure to ensure that the solution’s capabilities are accessible and quantified.

The author view in the TechSight/X Editor

The overview tab in TechSight/X CMS

Best Practices: Modern technology plus domain expertise

For example, while an organization can use a number of generic XML editors, a CSDB, or integrations between its technical information and other enterprise systems, it can fall short of getting the full value of the technology if not applied to its specific use cases. OEMs that call on product-based solutions adapted for the specific use of the aviation community show marked added value in terms of time to deployment, productivity, and lower overall cost. What’s more, these early adopters have researched the time, effort, and budget required to develop custom solutions based on generic technology. They have made the wiser decision to invest in providers with dedicated aerospace solutions with roadmaps set to mature through time based on the input of other aerospace customers.

Results

- Through the consolidation of multiple platforms, dramatic and quickly achieved reductions in content conversion costs, IT maintenance and administration costs, as well as lower training costs for end-users previously charged with working in multiple application platforms.

- Efficiency gains resulting from speedier review and decision-making processes through the use of both internal and external workflows to capture and respond to business and technical requirements from the manufacturer’s end customers.

- New revenue streams through improved business flexibility to meet customer needs for custom publications, automated delivery of content to external portals or data stores, or other revenue-generating customers or program-specific requirements that were difficult to respond to using legacy system capabilities.

- Lower cost per publication with improved support for custom publications, distribution of updated content to end-customer portal sites, and traditional content delivery mechanisms.

- Improved content consistency and accuracy thanks to increased re-use of material that is common across multiple products, publication types, or business units.

Airline Operators: Passive Participants in a Changing Industry

S1000D became the international exchange standard in technical information for civil aviation in 2004.

As of mid October 2013, 40 Boeing 787 Dreamliners had been delivered out of a total 131 orders.[1] Orders for the A350 stood at 725[2], and Bombardier had received more than 170 orders for its CSeries aircraft[3]. Each aircraft program uses S1000D for the basis of its technical information.

Northwest Airlines was the sole early adopter supporting multiple specifications in a single system among airlines. Delta gains that benefit through the merger of the two airlines. Outside of this, airlines have been slow in preparing for this change in the industry. Since new-generation aircraft are just now entering service, this is somewhat to be expected. However, because airline operators have removed themselves from discussions in the S1000D User Group, the ATA e-Business Program’s Civil Aviation Working Group, and other civil aviation conversations, they are not poised to scale their existing technical information management systems to meet requirements of new-generation aircraft programs.

Rather than highlight early adopters among operators, then, here we recommend to airline operators that they take proactive steps to learn about what new S1000D specifications mean for their maintenance and engineering teams as well as their technicians. Get involved with the ATA e-Business Program, attend the S1000D User Forum, discover training options available today. Read the previous articles on this series about who is impacted by new information standards and why; as well as options for charting an optimal course to meet new requirements. Explore options available to you from vendors offering solutions, request demonstrations, watch webinars.

Now is the time to start establishing plans. If you began making plans for a single authoring tool and IETP (interactive electronic technical publication) in the past (as airline operators started to do several years ago), dust them off and fill in the gaps. Start from this foundation and build a plan that uses best practices so that you can fully understand the decisions you need to make as you take delivery of new-generation aircraft. Transitioning from a legacy system to one that will meet your needs for years to come should start now. Rather than backing into decisions because you lack information, face the future and walk into it with the right information so you can make the best decisions to support your business and your customers.

Conclusion: new-generation technology for new-generation aircraft

On the airline operator side, we eagerly await to see who the early adopters of 21st century technical information management technology will be. As operators take delivery of the 787 and eventually the A350 and other new-generation aircraft, unless they take proactive steps they will have missed the opportunity to adopt solutions to keep their fleets running smoothly without incurring exploding costs, a lag in delivery of information to their technicians, increased risks of fines, and other consequences. If operators don’t soon join the conversation on technical information standards and technology, they’ll be in a reactive position; and we have to hope that the consequences won’t be negative for the flying public.

- ATA e-Business Program Membership Information http://www.ataebiz.org/meminfo/

- ATA e-Business Program, Civil Aviation Working Group (CAWG) http://www.ataebiz.org/apps/group_public/

- ATA e-Business Forum and S1000D User Forum 2014 http://www.ataebiz.org/forum/

The TechSight/X OEM Edition helps OEMs support their customers and suppliers in the production, ongoing revision, and automated distribution of aerospace technical information specifically designed to support multiple formats and standards — like iSpec 2200 and S1000D — with reusable, dynamic content to support a wide range of programs, specifications, and delivery formats.

The TechSight/X Aircraft Maintenance Edition is designed for airline operators that have ordered and are taking delivery of new-generation aircraft. It is a suite of applications for managing maintenance and engineering information across both existing iSpec 2200 and new S1000D program fleets — including the Airbus A350, the Boeing 787 Dreamliner, and others — so you can accommodate both existing and new-generation aircraft programs in a single system.

The solution delivers the most current, accurate, and regulatory-compliant information for all aircraft to technicians at the point of performance — and gives your airline control of your technical documentation for all of your fleets in a single system — relieving pressures of technical information management so you can retain your competitive advantages and focus on flying.

Comments (0)

There are currently no comments about this article.

To post a comment, please login or subscribe.