Articles

| Name | Author | |

|---|---|---|

| Case Study: Lufthansa: Digital Flight Deck | Matthias Schmitt, Flight Operations Engineering, Lufthansa German Airlines, and Heidi Brockmann, Product Manager and Senior Consultant, Lufthansa Industry Solutions | View article |

| Keeping a track of aircraft at all times | Paul Gibson, Portfolio Director, AIRCOM, and Paul Rainford, FlightTracker Product Manager, SITAONAIR | View article |

| EFB: Data Security & Connectivity | Capt. Brian Tighe, Deputy Chairman, and Capt. Kevin McCarthy, National Training Committee, Allied Pilots Association | View article |

| Case Study: A single EFB solution for a complex business | Christian Langvatn, Pilot & EFB Project Manager, Widerøe and Wim de Munck, Chief Technology Officer, AvioVision | View article |

Case Study: A single EFB solution for a complex business

Author: Christian Langvatn, Pilot & EFB Project Manager, Widerøe and Wim de Munck, Chief Technology Officer, AvioVision

SubscribeA single EFB solution for a complex business

Christian Langvatn, Pilot & EFB Project Manager at Widerøe and Wim de Munck, Chief Technology Officer at AvioVision share a recent EFB Ground Operations integration project

At the heart of this case study is the fact that in early 2016, Widerøe went live with its EFB-Ground handling integration project. But we’ll also explain the particular ground handling and flight ops challenges applying to Widerøe. So it will be useful to start by sharing with readers a little about Widerøe, the type of operations undertaken, use of EFB in the airline and why there was a need to integrate the EFB with the ground handling system. We’ll also cover the project itself, the system architecture and design, and the challenges of merging live systems.

AN UNUSUAL AIRLINE WITH EXCEPTIONAL CHALLENGES

Widerøe is the largest regional airline in Scandinavia with a history dating back to 1934 and now employing 3,000 people including 450 pilots and 380 cabin crew. 450 flights every day serve 43 domestic (all the airports in Norway) and three international destinations. The fleet is entirely Bombardier Dash8 with models from the Q400, 103, 200 and 300 series. Widerøe’s headquarters in Bodø are just North of the Arctic Circle and fairly central to the domestic network that covers a span of 1,100 NM – Norway is a long country and, as well as the lengths of even domestic flights, can also pose weather related challenges such as icy runways in winter.

There are crew bases and technical bases in Oslo, Bergen, Bodø, Sandefjord and Tromsø. Some might wonder why people would want to fly between small airports as little as twelve minutes flight time apart: but the journey by car would often take several hours because there might be a fjord in between. Most of the airports were developed by the Norwegian Government in the 1960s and 70s to serve small local communities with an infrastructure that would be available even in winter when the roads are usually closed and the ferries are sometimes suspended: Widerøe can usually still fly in to and out of those airports.

Sixty per cent of Widerøe Routes are commercial routes and charter operations with a further forty per cent Public Service Obligations (PSO) flown in a four or five year contract with the Norwegian Government. Many services require short take-off and landing operations on runways as short as 800 meters (2,600 ft.) with average flight times of 22 minutes (the shortest is 12 minutes). Because of the short flights, 14% of all block hours are actually used on taxi. Turnaround times are between 15 and 25 minutes which makes the operation quite unusual. So when it came to EFB development and integration, Widerøe had some special needs related to short flight times and short turnaround times. The system has to be working all the time with a lot of prepopulated data as well as generated data. Widerøe also has to cope with summers in which there is sunshine for 24 hours a day and winters when there is 24 hours a day of darkness.

WHAT IS THE EFB PROJECT?

Widerøe’s EFB project started in 2011 and the airline has been using the EFB with a pilot-attached iPad since the spring of 2014. They are soon to upgrade to a newer version when the next generation of iPad becomes available. The EFB selected was the AVIOBOOK® solution with Jeppesen FD Pro charting solution – Widerøe has always used Jeppesen and so it was a straightforward transition from paper to the App. AVIOBOOK is integrated with Sabre FPM (Flight Plan Manager) and the Sabre RM (Resource Management) system via Widerøe’s Enterprise Service Bus (ESB). The cockpit mount is from Fokker Services which offers both the power and the ARINC 429 data.

The EFB project was rolled out in phases. Phase 1 went live in 2014 with Jeppesen, FD Pro and Library, and Reports in AVIOBOOK. Phase 2, in 2015, saw some flight plan data and navlog from Sabre introduced into the App. In early 2016, Weight & Balance and load sheets went live and moved from the ground staff into the cockpit. This supported a positive business case; the challenging part was the need to achieve this without increasing Widerøe’s already tight turnaround times. That this was managed was a great success story for Widerøe. The plan is to introduce the Performance computer in the AVIOBOOK app in early 2017, and the next step will be an eTechlog solution.

Pilot training when introducing the EFB has involved no classroom training. Instead the airline created some step-by-step guides for the solution and is using the app AVIOBOOK SIM which is an exact copy of the ordinary AVIOBOOK app giving access to all live data. That way the pilots can play around with live data from the flight planning system any time they want to.

Widerøe has an in-house enterprise bus to which the systems are connected and Widerøe uses Airwatch MDM to control all the iPads. They are now also rolling out EFB to the cabin attendants using the AVIOBOOK solution on the iPad Mini, a dedicated AVIOBOOK CABIN application is in the making by AvioVision.

REALIZING THE EFB PROJECT

Custom functions and general enhancements

The working name for the project was the LPT (load planning tool) project and, for AVIOBOOK, it was a joint project with customers Widerøe and Air Greenland who both operate in the Arctic region with pretty extreme conditions. It was also not a routine project for AvioVision who, while they always try to promote a standardized product, will undertake special custom projects where, as well as developing a custom solution for users with particular requirements, they also develop the product or solution with special functions; in this case, it was ground handling integration but some of those new functions will be reusable for other of AVIOBOOK’s customers and will enhance the product. The goal was to replace the current load planning processes used in both airlines with a new tool and advanced processes. This was to save time and to support the business case for introducing the EFB with the load sheet and Weight & Balance changes.

Challenges of a complex project

It was quite a complicated project with many different stakeholders. They ranged across the sales department selling capacity; load planners; mail and cargo handlers who need, among other things, to know where the cargo is at any given time; the load masters on the ground (who need to know what they have to do to distribute loads, confirm the load on board a specific aircraft and deal with exceptional cases such as the loss of a bag or flight cancellation); gate staff and, of course, the pilots. You might wonder why an EFB provider would go into the ground handling area but, for AVIOBOOK, it’s part of an overall e-enablement strategy to ensure that all stakeholders, all the people around the aircraft, can communicate and get informed as quickly and efficiently as possible.

As an EFB provider, AVIOBOOK started from the flight deck with EFB software using various modules, many of them already used by Widerøe. They started to inform fuelers with fuel orders to ensure the right amount of uplift to the aircraft and also send information to the cabin. The infrastructure was further leveraged to deliver crew and flight scheduling… in short a lot of information for different stakeholders. Mail and cargo handlers are now involved with capacity planning for Widerøe as well as information provided to Load Masters for what they have to do, and instructions on how to optimize the distribution of the load. At the ends of that process, pilots will be informed in real time about the actual passenger load (PAX) as well as actual cargo and mail load. In the future there will be further functionality added into the solution, including aircraft status, MRO information and more.

TECHNICAL CHALLENGES

Technical challenges – functional

There were a number of functional technical challenges along the way, especially for AvioVision, developers of AVIOBOOK. They had previously focused on EFB on the flight deck so, before embarking on this endeavor, they undertook a thorough analysis of the domain with research, interviews, talking with stakeholders and on-site meetings to see what each person involved with ground operations had to do. The analysis was then combined with a more agile development approach which revealed a number of standard scenarios and common scenarios. Then, during implementation and even in roll-out many more cases came to light representing exceptions such as multi-leg flights within one flight number with the cargo and passenger handling challenges they pose. It all has to be traced for the load masters to know what has to be taken off, loaded and distributed to other connecting flights. There are often re-routings, even during flight, and there are cancellations, with all of it having an effect on the information that needs to be stored and to re-assign to flights. It further has to be combined with a very complex flight status and other information such as flight movement and information from the passenger booking system. Another functional challenge was the introduction of Automatic Load Distribution Rules to assist the load master with an optimized way of distributing the load among different holds and, in the cases of Widerøe and Air Greenland (see below), seat containers to carry loads in the cabin.

Technical challenges – operational

Along with the functional challenges, there were a lot of operational technical challenges. There was a high load on the system with a lot of stakeholders using the system in parallel and simultaneously. It also became clear that many stakeholders were accessing the system through older networks and old terminals like Windows XP and Windows 7 environments plus there was a need to support printing on dot-matrix printers, especially during the transition phase. On top of that, it was necessary to ensure that all of the new software and accompanying functions did not interfere with the already established EFB operations.

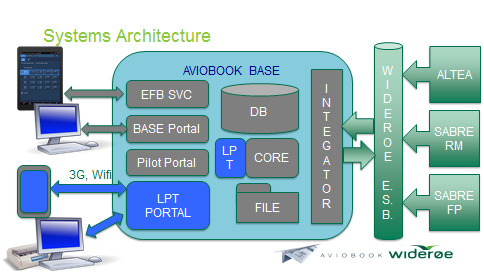

Figure 1

So, the system architecture (Figure 1) was built by extending the architecture already in place with ALTEA, Sabre FM and Sabre FP captured by the Enterprise Service Bus already existing in Widerøe. From there it is published into the AVIOBOOK base integration layer. New components were added to support LPT (load planning tool); but the system is also used in environments where load planning is not deployed so a separate portal was introduced with optimized workflow for those groups of users – mail and cargo handlers and Load Masters. It was also important to ensure that the normal EFB operations and dispatch operations were not interrupted.

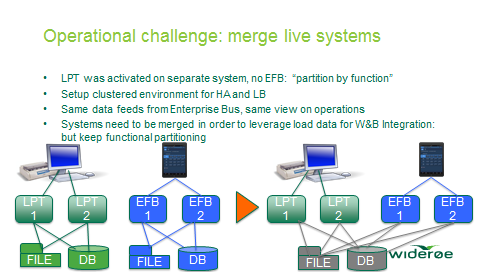

Figure 2

One of the biggest challenges was that this project had to go live very quickly so the software was built in about eight months. The LPT system went live with all load masters in all airports in February 2016 (Figure 2) and was, initially, only available for the load masters with mail and cargo handlers; with the EFB users (pilots) using a separate system. Both received the same data feed with ALTEA flight planning and crew scheduling sent to both systems in parallel and, at the time of writing, AvioVision and Widerøe were preparing to merge the two systems into one operational system. This has already been achieved on the Simulator or training system.

New concepts

A few new application concepts have also been introduced: one of them is the Load ‘Bubble’, an information bubble that tells the pilot about the progress of loading both passengers and cargo so that, while conducting flight preparation, the pilot can see at a glance how far advanced the ground staff is with the flight preparation. That concept already existed in AVIOBOOK in Collaborative Decision Making (CDM) and performance result bubbles.

NEXT STEPS

There will be a continuing program to finalize and stabilize the solution with a full fleet roll-out in late 2016 to Widerøe (after the busy summer period) and to Air Greenland. The load master functions will be extended to mobile devices. Some stations already use iPad for loading functions from a mobile portal which can support a variety of devices. That saves time because the load can be confirmed when closing the hold right next to the aircraft. Further into the future, other devices such as wearables and the cabin devices will be integrated into the solution in order to be able to provide information directly to the pilots.

Contributor’s Details

Christian Langvatn

Christian Langvatn has a background combining 20 years of experience working with IT and internet solutions and 12 years of experience as a commercial pilot. He studied Information Technology and Computer Science in the mid 90´s and has worked as a project manager, information architect/UI designer and developer in several different industries. He joined Widerøe as a commercial pilot in 2006, where he joined the EFB project in 2013 and is also involved in the development and roll-out of mobile solutions for the cabin.

Wim De Munck

Wim De Munck is CTO for Aviovision and part of the management team since its inception in 2010, supporting the organization with Systems Architecture, Technology Strategy and Solution Sales. As Project Manager he has introduced AVIOBOOK in several larger airlines. Wim has 25 years’ experience in professional IT consultancy and product development with companies such Sun Microsystems, General Motors and NAVTEQ as well as start-ups.

Widerøe

Widerøe is the largest regional airline in Scandinavia and carries around 2.8 million passengers annually between 46 domestic and international destinations. With more than 450 flights every day, Widerøe operates to more than twice as many airports in Norway than any other airline. The network consists of 60% commercial routes, and 40% PSO routes (Public Services Obligations) operated by a fleet of 41 Bombardier Dash-8 turbo-prop aircraft.

AvioVision

AvioVision is a young Belgian company created to bring innovative solutions to common problems identified in mission-critical industries, such as aviation. With AVIOBOOK® EFB the company wants to put the next generation Electronic Flight Bag software solution in the market. With an extensive aviation background, both as pilots and management executives, the founders of AvioVision have experienced the burden of keeping essential information up to date, looking for dispersed information in sometimes critical situations in the cockpit and the difficulties of communication between the airline’s back-office and its pilots worldwide.

Comments (0)

There are currently no comments about this article.

To post a comment, please login or subscribe.