Articles

| Name | Author | |

|---|---|---|

| Case Study: Using data for fuel efficiency at Cebu Pacific | Francesc Torres, Director Flight Operations Technical Support & Dispatch, Cebu Pacific, and Alexandre Feray, CEO of OpenAirlines | View article |

| Optimizing your investment in innovation | Phil Benedict, Customer Strategy Development, Closed Loop Consulting | View article |

| Aeroflot’s next-generation flight planning solution | Gesine Varfis, Advisor to the CIO, Aeroflot | View article |

| Latest Innovations: Live Weather Data for EFB Devices | Toby Tucker, Portfolio Director, Innovation Programs, EFB Services, SITAONAIR | View article |

Aeroflot’s next-generation flight planning solution

Author: Gesine Varfis, Advisor to the CIO, Aeroflot

SubscribeAeroflot’s next-generation flight planning solution

IT transformations, as Gesine Varfis, Advisor to the CIO, Aeroflot explains, are often more about the people than about the IT

This article is about the next-generation flight planning solution implemented by Aeroflot. Changing from one system producing flight plans to another is not like changing from BMW to Mercedes with the only concern being choosing colors.

During the change and implementation, there were some lessons learned: there is no best practice to adopt ‘as is’, no state of the art system not to be customized, there is no project without change requests. The most critical part is the data and interfaces. IT can drive business, but business needs to be taken on board. In our case a painful revolution was the best choice for achieving what we have achieved. All this is not as important as managing change, managing the people on both sides of the fence… vendor, consultants and airline.

According to McKinsey 70% of transformation projects fail to achieve their goals, largely due to employee resistance and lack of management support . Therefore, we prepared for this project not only according to the books by managing the classic DICE factors (duration, integrity, commitment, effort); we also enrolled different flight planning business consultants and IT vendor consultants to support us before and throughout the project.

WHERE HAS AEROFLOT COME FROM AND WHAT HAVE BEEN THE CHALLENGES?

Aeroflot has been in the market for more than 90 years. In 2009 when Vitaly Saveliev joined the airline, Aeroflot was an ailing national legacy carrier. The last dinosaur to die, to be protected or adapt to the global market. Aeroflot not only had to change its flight planning solution, but to change from the legacy carrier it had been to a competitive world class airline.

Change kicked off with a complete service overhaul. The onboard service was transformed leading us to win Skytrax awards in 2011, 2013, 2014, 2015 and in 2016. In that same year, Aeroflot has been awarded the status of an official four-star airline. This success helps to go the next extra mile after an intense race to bring customer experience to new heights in the area of digitalization and personalized interaction.

At the same time Aeroflot phased out all old aircraft while almost doubling the fleet size since 2010 with new aircraft acquisitions. As of November 30th, 2016 we grew from 100 aircraft in 2010 to 190, operating one of the youngest fleets in Europe with an average aircraft age of just 4.2 years. Today the first-ever Russian airline holding Aeroflot Group embraces the highly successful low-cost carrier Pobeda, Far East carrier Aurora and the newly consolidated Rossiya Airlines. The latter united the assets of a previous carrier with the same name, as well as Donavia and Orenair airlines.

To secure a seamless passenger experience and growth we also had to re-engineer the operations processes. That entailed relating operational targets to customer satisfaction with safety first; followed by reliability, on-time performance and connectivity. With the change of processes, organization, functions, etc. it was also necessary to replace our homegrown IT with a modern operations IT infrastructure. In our case, it was an IT driven business to ensure that the new processes and structures are supported. The decision was not for an evolutionary soft change, but a revolution. In the meantime Aeroflot implemented more than 20 new core systems apart from Flight Planning.

Implementation of the flight planning solution is a representative experience for what we have faced overall: it demonstrates the extent to which we re-engineered our whole IT suite with all its interfaces and data sources. It also took place in the heart of our airline in Flight Operations, in a very traditional pilot domain.

Although we have previously operated an IT flight planning solution, numerous dispatch and flight planning departments were engaged in producing the operational flight plan (OFP). The OFP creation was driven by numerous functions and stages, by manual processes feeding and checking the system assuring the correctness of the manual inputs. When the project started, Aeroflot operated with navigators accompanying flights on a regular basis. The new ways and the new system wiped out all that, catapulting flight planning into a new generation of Flight Planning process.

THE CONCEPT: FLIGHT PLANNING AS PART OF A NEW OCC AND HCC SET-UP

The concept was a stroll in the park when we prepared to get ready to play in the champions’ league. The re-organization of flight planning was completed in time; within a year we changed processes and the organization as well as functions and job profiles; all complemented by a re-design of the workplace environment and location. Even the chairs have been replaced, all ready and prepared for the implementation of a new IT system supporting this change. The concept was developed in close cooperation with an aviation consultancy. Our team and management was supported by leading flight operations experts. The key success factor was that the experts and our teams knew the business with all the details, pitfalls and issues that our team cared about. The discussion to determine the concept was one between equals to determine the new way in which we are to run business today.

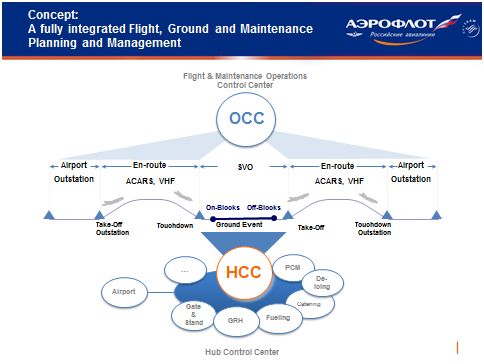

Figure 1

Today we operate an Operations Control Center (OCC) fully dedicated to flight operations and a Hub Control Center (HCC) allotted to ground operations (figure 1). With the IT infrastructure we had in place we opted for two centers instead of one. We have a classic OCC set-up with maintenance control, operations control, crew control and dispatch. Compared to other airlines we still have a METEO department as part of the OCC, due to the severe weather situations and infrastructure we face.

The HCC has been located next to the Airport Operations Control Center (ACC) to ensure a smooth introduction of airport collaborative decision making (A-CDM) while bridging the IT gaps. The proximity of the HCC and the ACC are vital to us given logistical considerations. Communication, fast exchange of information and decision making is vital to manage and keep the situation under control.

Regarding Flight Planning specifically, we changed from our traditional way of flight planning, which comprised three different locations with two different lines of reporting, to a centralized function as part of our OCC. Dispatchers are still present for crews in the briefing area, to provide them with the briefing packages in addition to the electronic charts we have. This is due to the fact that our civil aviation authorities still require paper charts as well as paperwork with personal sign-offs. Apart from the paperwork we have adopted self-briefing with dispatchers on stand-by if crews have questions or remarks. The flight plans are calculated 3 – 4 hours in advance. With the new system in place we are able to re-calculate the plans on the spot, if necessary. In the outstations we have the same paperwork to be delivered and signed. However, we have an ACARS equipped fleet, where the OFP (Operational Flight Plan) is directly sent to the cockpit. In-flight ACARS is used to update crews on weather or other relevant information, proactively as well as on request by crews.

When staff started to work in the new centers, at the beginning of 2012, with the legacy systems still in place, we commenced the implementation of the new IT systems that would support the centers. Before the Flight Planning we kicked off the Operations Control and Crew Planning IT implementation.

All systems were labeled best practice, to be implemented ‘as it is’, complemented by a very tight IT implementation plan. But, not only did the IT implementation take longer than planned, we also had to manage a very much higher number of change requests (CRs) than expected, to customize the systems for our business and the state-of-the-art concept of how we wanted to run our operations. This was when we had the first big gap to bridge. The IT matched the concept on paper in accordance with the understanding of all parties involved: consultant, vendor and Aeroflot. However, when it came to the details of the business, we learned that organizational changes do not necessarily change the old ways, an IT product does not fit the environment as it is, an integrated solution is not necessarily integrated, nor did the solutions support best practice as we defined it. However, the biggest technical challenge we faced, and are still dealing with, is the integration of all the systems.

Another lesson learned was that there is no fully integrated system; even systems under one label do not ‘talk’ to each other. Finding a responsible party for the sending and parsing of data, the definition of the format, etc. took time and effort, mainly taken care of by our IT department. Not having outsourced the development of the enterprise service bus (ESB) and the integration layer to one of our core IT vendors, but having it assigned to a local onsite company added to the complexity of the projects but, in the end, allowed us to control our IT environment and data flows instead of being controlled.

As at the time of writing, we are still in the process of closing the final gaps to ensure an automated supply of data and information. One of the issues we face is that we target to receive variable taxi times which, according to a recommendation by ICAO , should be supplied by airports, but are not supplied so far. The data are not only hard to source on a global basis, but even when we do receive them or when we decide to calculate them ourselves, our IT system is not capable to receive them without another CR. Within this framework the Flight Planning solution was implemented.

IMPLEMENTATION, ACHIEVEMENTS AND GAPS

As mentioned, the implementation plan was tight, but transparently structured:-

- Duration (D) with numerous milestones in place;

- The performance integrity (I) of the team was secured with different external flight planning experts on board;

- The organizational commitment (C) to change was in place with weekly regular meetings and with our CIO personally engaged; and

- Staff was prepared to provide the additional effort (E) required.

The Flight Planning specification was developed in close cooperation with the team, training was performed and the system for testing was implemented. This is when we faced the next bottleneck to tackle: when applying the first tests, the system results did not match user expectations nor were the results comparable to the old system; indeed, some were not acceptable at all. Time was lost in discussions and reasoning for the situation. Overall, faith in the new system was lost. At the end, the specification, training and set up had to be re-done and even when the second set-up of the new system was in place we performed parallel flight plan calculations to be sure that correct flight plans are produced. Regaining faith in the new system in an atmosphere of revamping has been hard on all parties involved.

The lesson learned here was that concepts and specifications do not cover it all. Even a detailed specification does not mean all parties have the same understanding. Vendors defend the product as it is while users do not understand the system in full. Especially when vendor and user interests are not aligned, the project is at risk. The conclusion is that the pre-sales approach should change. When selecting a car you drive it. Translating this to IT solutions it should be possible to try them and compare them with the current system. Users need to be involved and they need more knowledge about the system before specifications are signed off to be implemented as documented. Testing a solution before contracting would make sure that users trust the system and determine the system based on an equal understanding with the vendor. At the same time CRs can be contracted as part of the package, not as a later surprise.

The result after the fog lifted is that we now proudly operate the system. It is not providing the fully automated calculation of all routes with the most economic route calculation provided at one’s finger tip, but this is due to information not being available to the system. What has been achieved is a fully automated OFP calculation for European and North American routes. This is a significant increase in efficiency. It is only on the Asian routes where we are able to run more economic flight plans with manual intervention. We are still in the process of automating all data updates via interfaces but, even with this not fully achieved, we have almost doubled the number of flight plans per day without any need for additional staff. With today’s system in place we can grow without enlarging the dispatch team. We have alternative route options displayed, we can compare flight plans and see the deviations between the different routes, a big step forward for Aeroflot because we were more or less flying company routes before – they were always the same; not optimized and differentiated.

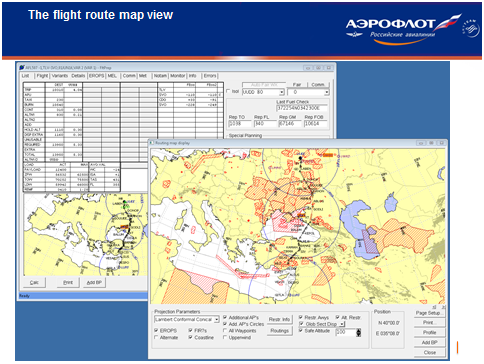

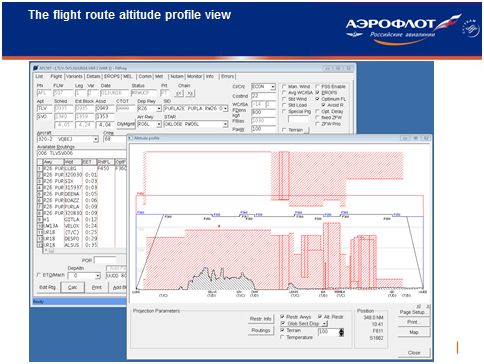

Today we manage our flight plans on two flight planning views: a map view (figure 2) and an overview of altitudes (figure 3).

Figure 2

Figure 3

Regarding the human factor, it took a while; but we are now at a point where we speak a common language with the vendor. It was easy on the concept side to match ‘worlds’ and ‘cultures’, but it was a more difficult journey on the IT side and took a lot of extra effort from everyone. What made it work was the top management’s dedication to success: we got the time to revamp and the overall commitment to success by the vendor and the team made things move when stuck.

Another lesson learned was that no change management can ‘implement as it is’. The transformation to success came when minds opened up to listen to the issues of the users and when the users started to trust and understand the ways of a more complex and automated system. At all stages of the project the experts knowing the business, knowing the software by heart and showing concern and interest in our way of doing business, have been the ones capable of managing the human factor. They broke the ice, tore down the walls and have been building the bridges for us.

Communication and change management should be part of any project management, not offered as an additional separately priced service. Soft factors are a significant success factor for any project, they can’t be ignored they need to be managed on both sides – the vendor and the customer side. By taking the soft factors into account, by managing expectations and different interests we could have avoided the loss of faith (above). Revamping and rebuilding faith took more time, took more efforts and in the end did cost us all more than change management as part of project management would have cost the vendor and us.

REMEMBER THE PEOPLE WHO WILL HAVE TO WORK WITH THE SYSTEM

With the system in place, we took the opportunity to review the project and rated the implementation in relation to Gartner’s peer insight® solution rating categories:

- Reorganization and Re-engineering;

- Engagement – Interaction with Business;

- Implementation;

- Integrated data feed;

- Performance;

- Support and Innovation.

The rating took place without the vendor participating. The team rating was complemented by a discussion which showed us that fact based ratings were affected by emotions that had not been taken care of.

The lesson learned here was that soft factors count, not only during the project but also beyond. They need to be managed in all stages of the project: pre-sales, sales, specification, implementation and after sales. It is never too late to take care of the human factor. For users it has been very helpful to exchange ideas on the user conferences with other users and product managers. It is also important to align organization concepts and process re-engineering with the IT capabilities right from the beginning. Make vendors not only responsible for delivery of a software product. Today IT companies implement solutions which can only be successfully implemented when soft factors are also managed.

Looking back, radical change is tough on people but we had to be radical with IT pushing the business a significant step forward. That said, our team has concluded that ‘we wouldn’t turn back and we’re looking forward toward the new visions we wish to accomplish whether it’s hard or not’.

HOW TO IMRPOVE: MAKE CHANGE PART OF DAILY BUSINESS

Change management is very important it should be an integral part of every IT replacement project transforming the ways of business. Change management skills are to be management skills. As of today, leading airlines can’t achieve operational excellence without taking IT into account. As of tomorrow, airlines will differentiate themselves by innovative leadership. The question is not whether IT drives the business or the business drives IT. It is IT and business driving the change hand in hand, either as part of an organization function (manager business processes and IT) or as part of the project management. IT project change management is not solely the airline’s responsibility. Change management and innovation must come with the vendor’s package and philosophy, as part of the product. Also the vendor’s tomorrow will be determined by how well they manage hard and soft factors over the product life cycle and by how adaptive and innovative their solutions are to give customers the cutting edge cost savings or enhancements in efficiency and quality.

All in all, airline IT solutions should be evaluated and rated. Neutral institutions like Skytrax made it worthwhile for us to invest in upgrading our services. Vendor ratings should be a regular exercise. This will not only improve the evaluation of solutions and IT implementation projects it will also improve the products and boost innovation and start up initiatives. Moreover, interface and best practice standards with which vendor’s need to comply should be defined. As an example, the integration of variable taxi times or CDM times should not be times individual airlines should fight and pay for, but an internationally agreed system standard.

WHERE NEXT AT AEROFLOT?

“… after the game, is before the next game”. Having achieved an important milestone our ambition is to further enhance our flight planning, flight tracking and in-flight support capabilities. The vision is to be one of the airlines which will drive tomorrow’s on the ground and in-flight trajectory management. We plan to develop the capability to update flight plans at all times when significant parameter changes occur (e.g. weather, ATM congestion, etc.) which would make a new flight plan safer, more efficient or faster to reduce a delay, to save connections and improve our on time arrival performance for customers and third party resource management. The target is fully integrated flight planning by taking operations control, airport and enroute CDM, traffic awareness and traffic predictability into account; translating it into a full situation and predicted flight route awareness for crews and dispatchers to reroute airborne flights, to negotiate short cuts or to negotiate other route proposals with ANSPs (Air Navigation Service Providers).

The next step is to analyze historic data to develop our predictive capabilities based on detailed data mining and deviation analyses (to take account of how the aircraft has actually been flying and taxing) by detecting change and delay parameters for taxi times, route profile and level changes. We are discussing something like inflight, take off and taxi ‘delay codes’ and to learn and incorporate the causes of deviations.

Contributor’s Details

Gesine Varfis

Gesine joined Aeroflot Russian Airlines as COO advisor for organization and process improvements in 2013. Today she is advisor to the CIO enrolled in upgrading Aeroflot’s OPs systems targeting a fully integrated solution of systems, data sources and mobile solutions. She was previously engaged in the Operations Control Center and Hub Control Center re-engineering and IT implementation projects. Before she joined Aeroflot, Gesine worked for Lufthansa Consulting as a Managing Consultant specialized in Operations and Maintenance.

About Aeroflot

Aeroflot is Russia’s flagship carrier and one of the largest airline groups in Europe. In 2015, Aeroflot carried 26.1 million passengers (39.4 million including subsidiaries): Aeroflot and its partners in the SkyTeam global airline alliance serve 1,062 destinations in 177 countries worldwide. Aeroflot operates one of the youngest fleets in the world, numbering 189 Airbus, Boeing and Sukhoi airliners. It has a European Community Safety Assessment of Foreign Aircraft (SAFA) Index, the main globally recognized safety parameter, comparable to global peers. The first Russian carrier to enter the IATA Operational Safety Audit (IOSA) register, Aeroflot has successfully passed the IATA Safety Audit for Ground Operations (ISAGO) and is fully ISO 9001:2008, ISO 14001:2004 compliant. In 2016 Aeroflot became the first Russian airline to be awarded Four Star Airline status by Skytrax in recognition of the high-quality of its customer service, and was also named Best Airline in Eastern Europe for the fifth time at the Skytrax World Airline Awards. In 2015 Global Traveler named Aeroflot one of the 10 best airlines worldwide for on-board cuisine.

Comments (0)

There are currently no comments about this article.

To post a comment, please login or subscribe.