Articles

| Name | Author |

|---|

Big Data Management for Optimized Fuel Efficiency

Author: Nico Metzger, Marketing Manager, Airbus Services and Customer Support, and Nishant Balakrishnan, Business Development - Airbus Smarter Fleet Solution (Airbus-IBM JIA) Senior Managing Consultant & SME Global Center of Competence- Travel &Transportation, IBM Global Business Services

SubscribeBig Data Management for Optimized Fuel Efficiency

Airbus Smarter Fleet powered by IBM

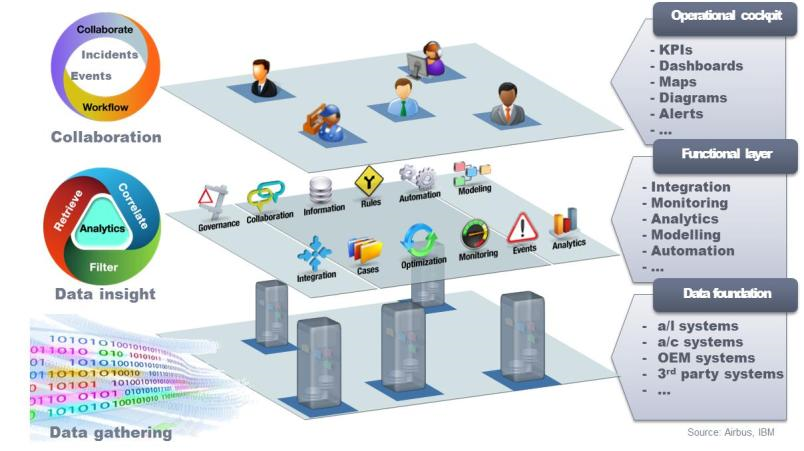

Airbus and IBM are working together to transform Airbus’ fleet solution offerings, which will provide airlines and operators with advanced IT services for maintenance, engineering and flight operations. These fleet service offerings will enhance operational efficiencies, help airlines to manage their aircraft more effectively and improve customer service by smarter use of ‘big-data’.

Fuel efficiency has been identified very early as one of the key areas where the optimized management of big data can bring large benefits for airlines. This is why ‘Smarter Fleet for Fuel Efficiency’ is one of the very first fields for application of this process from Airbus.

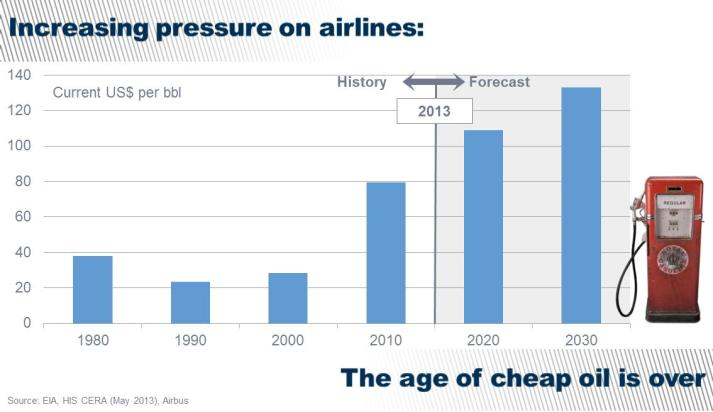

The age of cheap oil is over

If we look a bit further back into the past we see that for a very long time the costs for fuel were not of predominant importance for airlines. In fact, up until ten years ago the price for a barrel of oil had never exceeded $40. From the early 2000s onwards, the price of oil started to rise inexorably and has now passed the mark of $100 per barrel.

The common wisdom might well tell us that ‘no one believes forecasts, but everyone wants to hear them’: nevertheless, it is unlikely that the price of oil will ever again come down to where it was ten years ago. On the contrary, one can conclude that the age of cheap oil is over and that the fuel cost pressure on airlines will continue and possibly increase.

Getting the math right

In the light of ever increasing oil prices one should not forget the high value money savings that can be generated through even very little savings in fuel burn. A typical airline of some 50 aircraft, like the Average Airlines depicted below, requires some 600,000 tons of fuel each year and has to pay an annual fuel bill of almost $600million under current market conditions.

Current airline fuel saving potential

The fundamentals of these initiatives have been the optimization of existing processes and procedures. For flight operations this includes notably the optimization of flight profiles in order to fly the most efficient routing at the most efficient speeds and altitudes, and further operational procedures such as reduced utilization of the Auxiliary Power Unit (APU) or one-engine taxi procedures on the apron. In aircraft maintenance the attention has been turned to preserving, restoring and further optimizing the aerodynamic characteristics of the structure, and the consequent removal of needless weight from the aircraft.

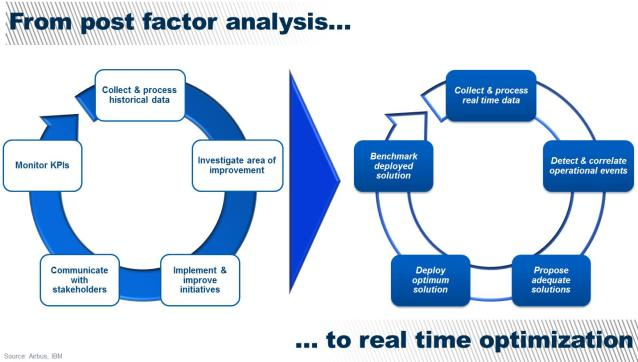

A further step has been taken with the exploitation of historical data from several sources to improve operations. A large number of suppliers on the market today provide IT-systems that allow, for example, a detailed post-flight analysis to retroactively detect fuel overconsumption or that help to determine the most efficient cost index for a planned mission.

All of the mentioned initiatives and techniques have already proven to be helpful. Airbus believes that overall fuel consumption could be reduced by as much as eight percent, if the full panel of measures is efficiently utilized and fully synchronized.

Future airline fuel saving potential: step change required

- The efficient gathering of large amounts of data from multiple sources;

- The deployment of appropriate techniques to extract the value from data;

- The cross-domain collaboration of several functional entities within the organization;

- The help to real-time decision making and reacting to operational incidents.

Aircraft raw data

Big data

The challenge arising from big data is not simply the volume of data, as the name might suggest. Volume, though, does play a major role, especially when one considers that much of this is historic data that cannot be accessed through classic queries because it is simply too large. The challenges are multi-layered. Having said that, fuel related data generated could be large volume once FDM, ACMS (Aircraft Condition Monitoring System) and FCPC (Flight Control Primary Computer) are considered. Traditionally, airlines have been storing FDM or ACMS data but seldom are they used to their full potential especially in co-relationship with each other. Also the velocity at which new data is produced and needs to be processed can pose issues for conventional techniques of data reception and treatment. Half of in-flight data is generated by engines in a six hour flight not to mention about the in-flight and on-ground/maintenance data generated by new generation aircraft. The airlines would need to adapt to new techniques to manage and make the most of these data. An advanced data management system, such as one required for fuel efficiency management, needs data from numerous sources and must be equipped to deal with a large variety of data, which comes from sources like the maintenance information system (MIS), flight planning, crew scheduling, in-flight, historical or other external sources such as weather, ATC (Air Traffic Control) and seasonal variations, to cite but a few. The data coming from these sources can range from being highly structured like application data to highly unstructured such as textual data.

Additionally, the accuracy of data must be assured. It is self-evident that a decision can only be as good as the information on which it is based. The source and information need to be trustworthy so that operations can confidently make data-driven decisions that rely on more than judgement alone. Leading airlines need to use ‘smarter’ technologies to harness big data to define fuel management strategy along with other departments such as maintenance, commercial, customer loyalty, in an effort to make more holistic and cost-‘wise’ decisions. This would lead to further opportunities that may, as yet, be difficult to comprehend or anticipate today.

Real time decision making assistance

How to make the step change

Contributor’s Details:

Airbus

Airbus is the world’s leading aircraft manufacturer of passenger airliners, ranging in capacity from 100 to more than 500 seats. Airbus champions innovative technologies and offers some of the world’s most fuel efficient and quiet aircraft. Airbus has sold over 13,600 aircraft to more than 360 customers worldwide. Of these, more than 8,100 aircraft have been delivered. Airbus has design and manufacturing facilities in France, Germany, the UK, and Spain, and subsidiaries in the US, China, Japan and in the Middle East. In addition, Airbus provides a worldwide network of customer support, training and spares centres.

IBM

International Business Machines Corporation (IBM) is an information technology (IT) company operating in five segments: Global Technology Services (GTS), Global Business Services (GBS), Software, Systems and Technology and Global Financing. GTS primarily provides IT infrastructure services and business process services. GBS provides professional services and application management services. Software consists primarily of middleware and operating systems software. Systems and Technology provides clients with business solutions requiring advanced computing power and storage capabilities. Global Financing invests in financing assets, leverages with debt and manages the associated risks.

Comments (0)

There are currently no comments about this article.

To post a comment, please login or subscribe.