Articles

| Name | Author | |

|---|---|---|

| White Paper: What’s up with Aviation IT? | Paul Saunders, Director, Conduce Consulting | View article |

| Case Study: Can airlines pull IT all together? | Vishok Mansingh, Asst. Vice President-Eng Logistics & Systems, Kingfisher Airlines Ltd | View article |

| Case Study: Aircraft Maintenance Management and Control Software Systems do not require long implementation schedules | Aer. Eng. Gustavo Daneri, Maintenance Director, Sol Lineas Aereas | View article |

| Case Study: BoB and ERP: Working together, IT works | Fernando Moura de Lucena, Manager Business Solutions IT, VRG Airlines (Gol Group) | View article |

| White Paper: Are you ready for an Enterprise Wide MRO System? | Sharhabeel Lone, Partner Global Business Strategy, SAKS Consulting | View article |

Case Study: Aircraft Maintenance Management and Control Software Systems do not require long implementation schedules

Author: Aer. Eng. Gustavo Daneri, Maintenance Director, Sol Lineas Aereas

SubscribeAircraft Maintenance Management and Control Software Systems do not require long Implementation schedules

Aer. Eng. Gustavo Daneri, Maintenance Director, Sol Lineas Aereas explains how a three week implementation program for a complete multi module solution has produced companywide benefits

Sol Lineas Aereas commenced operations in August 2006, having been incorporated in 2005. Based in Santa Fe, Argentina we launched the service with SAAB 340 A aircraft. Following five years of strong growth, and to accommodate this growth, we have this year signed agreements for two additional Saab 340 B Plus aircraft to join the fleet during April. This will bring the fleet size for the second quarter of 2011 up to eight Saab 340s, including the two Saab 340 B Plus.

Like many start-up airlines, in the beginning we did not utilise all available tools to provide optimum productivity and ensure the most reliable service to our customers. We had to concentrate on the core function of getting the operation under way. However, with all the pressures involved in this we found that our service delivery was not what we had expected. In light of this, the technical department were tasked by the Board to investigate ways to:

- Reduce aircraft time on the ground resulting from scheduled and non-scheduled maintenance, in order to increase fleet utilization. This would allow Sol to add new destinations to the network with increased frequencies to destinations already served.

- Increase the dispatchability of the fleet to meet the schedule or other management demands and reinforce Sol’s image as a regional leader.

- Improve and optimize the planning and forecasts of component and materials consumption (rotables to consumables) to reduce the impact on cash flow.

- Control and reduce maintenance costs.

- Improve planning and logistical supply management.

- Carry out statistical analysis of failures and breakage.

- Maximise preventive maintenance.

- Strengthen and consolidate maintenance management to support continued growth.

- Obtain predictability.

Further to this the finance department requested that the solution should, as a minimum, offer:

- The ability to plan the financial resources allocated to aircraft maintenance and to reduce AOG (aircraft on ground) situations that seriously affected cash flow.

- An Interface to the Accounting Management System to update and quote the stock of rotables in real time, optimize the consumption of consumables, and quantify repairs and maintenance of rotables.

As with any new airline finding its feet the budget for the new system would have a limit: however, our expectations would not. We set up a team within the maintenance department to set the objectives and wish list for each section within the department. This team included representatives from each section to ensure all business processes were included in the objective setting process. In the end the committee had representatives from each of engineering, planning, maintenance and logistics departments. We felt it was critical to understand what we wanted before we went out into the market to look at products. The core areas identified fell broadly under the following headings:

- Provide precise information to the maintenance staff in relation to scheduled maintenance, describing the resources needed (materials, tools and HHRR – human health risk resources), verify the availability of information in advance and make a more efficient use of those resources.

- Perform analyses of system reliability and components failure monitoring, and implement corrective actions; not only to improve reliability and fleet dispatchability but also to reduce maintenance costs.

- Reduce turnaround times for rotables reparation in order to keep stock in place when adding new aircraft.

- Reduce the stock of rotables in quarantine, stand by or pending failure confirmation, in order to make a more efficient use of them.

The team had a strong belief that whatever system we selected it should be extremely user friendly for those on the front line as well as those in the supporting areas. If we could not get all staff to utilise the system it would fail before we even began.

It was also considered important to ensure that, when we went to the market we selected a product that could grow with us; clearly, our needs would grow as our operation expanded. This was a process we wished only to enter into once in the lifetime of the company. There were those amongst the executive team that had had bad experiences in the past with companies in which they had worked. Therefore it was very important for us to get it right first time. The other matter consistently raised during our research was the implementation project and the extent to which this would draw on our limited resources. Many people were telling us to plan for six to 18 months of heartbreak. We were certainly willing to do so and understood this was not going to be easy but felt that there must be something on the market that worked more efficiently than those timescales.

The market, we found, included software systems at a number of levels. It was quite daunting at first just to sift through those with which we should even begin to engage. However in the end through internet searches we identified ten companies to contact. After initial contact we whittled this number to five, based on price and functionality. For us COTS (commercial off-the-shelf) software was the only option. Again we wished to maximise our functionality but to do this within a budget. We did not wish to be the testing ground for a new product so only products with a proven track record were selected.

Once we had identified our three short-listed contenders we set up a live presentation all of which we did on line to see each system in action. We then requested a quote from each and, most importantly for us, a list of customers who were using the software in a live operating environment. From this point we selected our top two choices and invited them to our facility for a full presentation of their respective products (we kept choice three on standby).

Making our final selection, based on all of the above criteria, Volartec’s Alkym® Management and Control System for Aircraft Maintenance was the system that we chose. The product had scalability and multiple modules available which allowed us to select what we needed now with the assurance that as we needed further add-ons they were already available. We started with the core modules of Engineering, Planning, Maintenance Control, Reliability, Purchase & Repairs, Inventory, and Human Resources. A year later, we added the Quality Assurance module; plus some additional licenses to cover our growth. Also available to choose in the future, as and when we needed them, were Sales, Technical Library and Production Kiosk.

For Sol Lineas Aereas the main reason for choosing Volartec over the others was the promise that we would be operationally live in a very short time; they explained that the normal project time averaged just four to five weeks. Volartec would provide a project team to come on site and work hand-in-hand with our resources to ensure this deadline was achieved. In fact, once we sat and discussed the options available we were promised that our project could be completed in three weeks and this sealed the deal. In hindsight, I’d have to say that several people in our executive team were sceptical of this claim. Nevertheless, the onsite project that we paid for was scheduled for three weeks and, to ensure optimum use of this time, the Volartec team did what they termed ‘a pre-implementation phase’ prior to their arrival, the cost for which was covered by Volartec. During this process we provided them with all our current procedures, documentation and data on the existing fleet. We also provided remote access to our servers for their IT people to do the initial configuration of Alkym.

The onsite visit was conducted as promised and included the configuration of Alkym to match our business processes plus all of the training of our personnel. They also trained us on migrating data into the system as well as bringing a number of our aircraft completely into the system. When completed we had our fleet under management in Alkym. The last days of the project involved onsite support for our people to ensure they were fully up to speed and an explanation of how the on-going support system works. Being an ISO 9001 certified company, the documentation supplied in relation to Alkym was vitally important to us and everything was delivered in exactly the right format.

This was a very intensive period and the one negative for the project would be getting our own resources to be able to allocate the time to ensure we met the project targets. In the end we did get there but it was difficult to stretch in so many directions at once.

The tight integration that Alkym provided in the modules chosen was a benefit that we could realise almost immediately. Implementation of the Planning and Engineering modules allowed us to manage the Aircraft Maintenance Plan, scheduling the plan and forecasting the required resources.

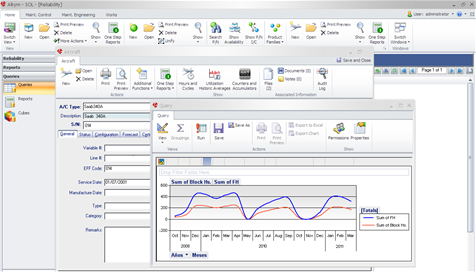

Screen Shot 1: Alkym Queries – User customisable data mining tool showing graphical output of Aircraft utilisation

The Maintenance Control module helped the line maintenance personnel to obtain the necessary information to plan working actions. This module carries out control of MEL (Maintenance Expenditure Limit) and deferred maintenance items expiration, eliminating potential AOG situations that would have arisen without the application of this module. Through alerts (via e-mail or on screen), the system notifies which rotables have exceeded the allotted time in quarantine. Another alert, for example, points to the arrival or stage in delivery process of materials requested to accomplish a particular task. When a rotable is removed from the aircraft due to an ‘out of service’ event, the system will alert if it is within warranty and therefore a claim to the vendor can be arranged. This would help to reduce repair costs considerably.

The Reliability module provides statistical reports on fleet utilization, dispatchability, etc. But basically, it allows for the reliability analysis of systems and components in order to comply with regulations and configure necessary warnings so that the engineering department can carry out failure research and corrective actions.

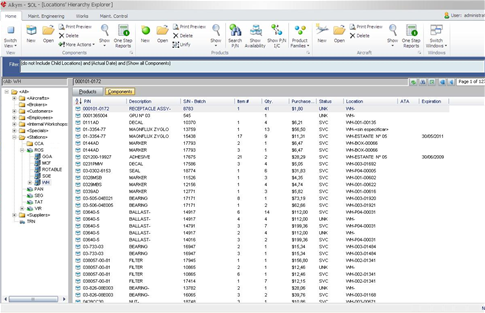

A smooth management of all our logistics needs is now catered for by those applicable modules. This facilitates the monitoring of repaired components and avoids the possibility of loss during tracking and shipping materials back and forward. The interchangeability of P/N (part number) is also a very useful capability of the system. Including people from the engineering area in the approval of workflow contributes to better control over components reparation costs.

The functionalities of the Purchasing module support all the necessary processes of purchasing including the reception functionalities which facilitate compliance with parts admission standards, from an administrative and QC (quality control) standpoint.

Screen Shot 2: Alkym Location Hierarchy Explorer – Detailed information on all products and components under management

Regarding the implementation process: by the time we were pre-implementing Alkym, Sol was operating two Saab 340 A aircraft and as soon as we started the implementation, two new Saab 340 A joined the fleet with the arrangements in place for adding at least two more aircraft in the short term. As in any growing company, our human and technological resources were assigned to the day-to-day operation and to the reception of aircraft, so we were not able under any circumstances to allocate resources for an extended period during the implementation of the new software. Therefore, we requested of Volartec that the implementation project should not exceed 30 days, in order not to interfere with our operation.

Volartec’s response to this bigger issue was positive, presenting an implementation project of just three weeks, which included the remotely conducted pre-implementation phase (see above). With the proposed implementation plan, much responsibility for the success of the project rested on our side. We needed to provide early remote access to our server, our procedures and quality manuals, as well as maps of our most important processes and all the digital information of the maintenance records for data migration related to the two aircraft currently operated and the two new ones to come. Since I was the sponsor of the project, I had to involve myself very deeply in it, appointing one of our engineers as the project manager, who should closely monitor the entire process, allocate the necessary resources, solve the problems that occurred and report to me daily.

Having all the information provided by Sol at an early stage, Volartec conducted the analysis of our processes, designed the configuration of Alkym in total compliance with our procedures, and performed the data loading remotely. After that, a team of four people were positioned with a work schedule that included the validation of the operational model to configure Alkym (previously designed during the pre-implementation process), the introduction of Alkym on our server, and onsite training and support following deployment of the system. At the outset we considered that the project could be delayed at least a week while still remaining within the goal of not exceeding the 30 days timetable. However, against this prediction, and thanks to the work done by Volartec´s team during the pre-implementation phase, we were able to finish the project within the expected time.

Conclusions

I mentioned at the start of this case study that setting up a team was part of our plan. This team now includes the Volartec team as we have forged a close working relationship with them. Also key was that our implementation was designed to bring benefits to the whole company and the success or failure of the project would be determined by our heads of departments. So in conclusion I return to some of these key executives in the story to see what they think.

First I spoke with Gustavo Cebreiro, our Executive Vice President, now that Alkym was in a live operating environment and he had this to say:

“The improvements implemented by Sol maintenance department allowed us to reduce contingencies and AOGs, which resulted in an improvement in cash flow for the company. We have also managed to increase aircraft utilization, reliability and fleet dispatchability. At the time we decided to implement Alkym we were going through a difficult situation, it was critical because we needed a consolidation to keep on growing. We had to improve mainly on our performance of tasks when aircraft were on ground for a short period of time. We met this goal through several improvements such as increasing the automation of procedures and streamlining our processes. It was the main priority for top management”

Then we would need to examine whether the processes have improved and for this we turn to our Quality Assurance Manager Eng. Mariano Mariño.

“Since implementing Alkym, we have obtained more and better information that allowed us to reduce corrective actions and devote our time to predictive actions, as well as to perform failure statistics. As an example, the planning department sends information in advance about scheduled maintenance containing the resources that we need, like tools and spare parts which allow us to plan in a more efficient way the inspections and calculate human resources which will be assigned. Thanks to this information we could put the inspections together and reduce time on ground for aircraft.”

These comments are supplemented by those of our Quality Chief Eng. Pedro Solis who says:

“Now, we can check our resources availability, or ask for those resources in advance if they are not available. We can also undertake fault monitoring of systems and components and query the record of failures or repetitive failures. Through an e-mail alert we avoid having components in quarantine for a long time. Ultimately, we have achieved a better utilization of our human resources”

We turned next to the logistic functions where much of our waste was occurring and are proud to have comments like those of Marcelo Vicent, Logistics Manager: “We have considerably reduced AOG situations, reducing, at the same time, the turnaround time of reparations. What is more, we didn’t increase our inventory stock level although we have accepted new aircraft. But most importantly, we have succeeded in providing predictability to the company’s finance department.”

My own conclusion would probably be that there is always room for improvement, but through changes in the management system and the correct utilization of Alkym we have implemented solutions that have largely solved our major problems. We have achieved all the objectives and moved from a reactive to a proactive situation. The use of a tool like Alkym was essential to manage changes and achieve objectives.

So to sum up, a quick implementation of a full function maintenance management system is indeed possible and Sol Lineas Aereas has proven that it can deliver affordable and excellent companywide results. The key to the implementation process is to have a focused and dedicated project team consisting of key executives from within the airline and above all to rely upon the knowledge and experience from your software vendor during this difficult process.

Comments (0)

There are currently no comments about this article.

To post a comment, please login or subscribe.