Connected aircraft, explains Mario Sabourin Sr. Product Manager EFB at SITA, have the potential to reduce turnaround times, cut MRO costs and let passengers play Xbox Live during the flight. Here’s how it is going to become reality.

What if your passengers could stream videos or hold conference calls during a flight? Or your cabin crew could validate credit card transaction in real-time, reducing the level of fraud? What if maintenance staff at your outstations already knew which parts needed repairing before the aircraft landed..? or pilots could receive real-time weather reports from aircraft flying ahead of them? To be fair, some of this can already be done with low bandwidth systems in place today, but what if passengers, pilots and cabin crew could all be doing their individual things simultaneously? It would provide passengers with a richer infotainment and interactive experience, boost aircraft utilization, enhance safety and increase operational efficiency.

The vision of truly connected aircraft has been talked about for a long time, but it is only over the next few years that the pieces of the puzzle will be sufficiently mature to transform the vision into a realistic proposition.

Next generation aircraft

Today, there are only around 300 new generation aircraft in service, equipped with advanced sensor technology and connectivity capabilities. But over the next decade this will increase rapidly to over 10,000 aircraft, including the Airbus A350 and Boeing B787 Dreamliner. By 2022, approximately 35% of the global fleet will effectively be flying data centers.

Insight paper

Each of these new generation aircraft has the potential to generate a huge amount of data every flight with estimates suggesting as much as several terabytes on a single transatlantic trip. The ability to process this data in real-time, both in the aircraft and on the ground, is going to open up a wide array of new applications.

Consumer trends

Another defining trend is the increasing expectation of passengers to have access to the same mobile experience in the air that they get on the ground. In many cases that means unlimited downloading and a growing expectation of free Wi-Fi similar to what they receive in coffee shops, restaurants and at many airports. As well as that, the gradual loosening of regulatory restrictions on the use of personal electronic devices (PEDs) during take-off and landing is further raising passenger expectations. Altogether, it is putting airlines under tremendous pressure to make high-speed, in-flight connectivity a standard feature of the flying experience.

Broadband satellite connectivity

Currently, most ground communication with aircraft takes place with satellites using the radio frequency L-band. It is both expensive and has low bandwidth making it unsuitable for large numbers of passengers to surf the web or for communicating the huge data sets produced by the latest generation of aircraft.

However, a number of new generation satellite technologies are due to come on-stream in the next few years that will transform the availability and cost of in-flight communications. It is eagerly anticipated, with 73% of airlines expecting to have on-board connectivity by the end of 2017, according to SITA’s latest Airline IT Trends Survey.

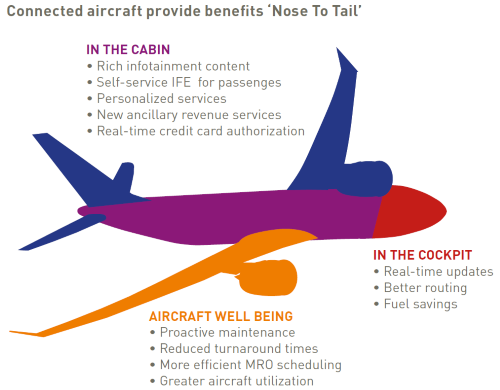

Connectivity brings ‘nose-to-tail’ benefits

When you take these trends and start connecting them together there are some huge opportunities revealed for airlines from having a richer information exchange with passengers and crew right through to automating routine processes in and around the aircraft.

In the cabin

Almost every person travels with a mobile device and for the vast majority it is a smartphone, tablet or laptop loaded with apps and entertainment. SITA’s 2014 Passenger IT Survey put the figure for passengers carrying any mobile device at 97%, with 18% of passengers carrying all three. This phenomenon is generating a pent-up demand from passengers for in-flight connectivity, putting pressure on airlines to deliver faster and cheaper connectivity solutions. In short, connected aircraft can significantly improve the passenger’s in-flight experience by allowing digital travelers to use their own devices to access entertainment of their choice, such as films and games, and stay in continual contact with life on the ground.

Continual in-flight connectivity will also open up more opportunities for cabin crew to interact with passengers, personalizing the service. By 2017, 81% of airlines plan to deploy or trial wireless tablets for their cabin staff, according to the 2014 Airline IT Trends Survey. With the tablets connected to back-office systems there will be three benefits for airlines.

First, cabin crew will be able to provide passengers with up-to-date information concerning their travel, such as baggage status or connecting flight status, and even re-book passengers if necessary.

A second benefit is the ability to digitalize paper processes, such as form filling, in areas like onboard inventory or fault reporting. This provides actionable information to ground staff preparing for the aircraft arrival, speeding up turnaround times.

Wireless tablets will also give cabin crew the opportunity to offer new services to passenger that can generate ancillary revenues. This could include providing access to premium IFE (in-flight entertainment) content or even making onward travel reservations. With credit card authorizations possible in real-time rather than post flight, the incidence of fraudulent transactions should also decrease.

In the cockpit

Moves to digitalize the cockpit have been going on for a number of years since the turn of the century when Electronic Flight Bags (EFBs) first started replacing a case load of paper flight manuals and other documentation. Today, pilots can access pre-loaded flight documentation on a lightweight tablet costing just a few hundred dollars. With the latest generation of aircraft, these simple Class I EFB solutions will become far more sophisticated by being transformed into an integrated, always connected node on the airline’s IT system.

This will help pilots make smart decisions by giving them real-time access to critical data; both that which is generated by the aircraft while flying and from ground-based systems. It will improve operational efficiency and save fuel from better route planning. In addition, maintenance staff will be able to access the data from the pilot’s logbook while the aircraft is in flight, to update planning schedules, leading to faster turnarounds.

Maintenance and aircraft well-being

New generation aircraft are fitted with large numbers of sensors and built-in health monitoring systems. For instance, the Airbus A350 measures 440,000 parameters. The onboard IT system can relay information on the condition and performance of aircraft parts to ground-based maintenance staff, as well as monitor the software elements that keep the plane operational.

Receiving advance notification of a defect on an incoming aircraft can allow the ground crew to have the replacement ready by the time it lands. This ability to perform automatic fault detection and diagnostics can drive efficiencies in maintenance schedules, keeping aircraft longer in the air; where they generate revenue. Ultimately airlines will be able to use the data from their aircraft to build predictive models on the lifecycle of parts and take action to replace them before a problem occurs. This type of predictive maintenance will cut aircraft downtime by reducing unnecessary preventative maintenance and increasing the efficiency of MRO operations.

e-Aircraft require a new mindset

While technology advances are laying the foundations to exploit new generation aircraft, airlines will struggle to do so without fundamental changes to the way they manage their fleets.

A holistic approach

Airlines will need to adapt the way they take decisions on equipping each aircraft across their fleet. Current practices often mean passenger and cockpit operations are owned by different stakeholders within the airline. The result is discreet IT projects run in individual silos without regard to the wider economies of scale and re-usability of IT components. This approach encourages inefficiency through a low degree of commonality in the design and integration of technologies.

Access to reliable IT infrastructure

If airlines are to extract the full benefit of their investment in connected aircraft they will need to integrate the aircraft into the airline’s IT environment, in particular back-office systems. To do this the airline will need either to deploy or have access to reliable and secure IT infrastructure, not just at hub airports, but also at outstations.

Today, most data exchanges with the aircraft, whether en-route or on the ground, involve using a variety of different communication infrastructures. There are multiple ground-based ‘last-mile’ connectivity options, including hard-wired IP, as well as wireless based options such as Gatelink, Wi-Fi and cellular. Given the country to country differences in costs, bandwidth, coverage and political/legal factors, this is going to require a great deal of careful management.

Handling a massive increase in data

Dealing with the sheer volume of data from aircraft and making sense of it is going to present a challenge and one that will multiply as more new generation aircraft enter service. Today, airlines handle the issue by offloading only a subset of critical performance data for OEMs from onboard systems, but this limits the potential benefits. For most airlines a scalable cloud-based solution will provide the most efficient approach for processing and storing the data, but it will also need new tools to filter and perform predictive analytics on that data, as well as overcoming the challenge of getting the right data to the right place and the right people at the right time.

Increased complexity of Loadable Software Aircraft Parts (LSAPs)

The advanced capabilities of new generation aircraft necessitate the need for more software applications to manage them. In turns this requires significantly higher and more complex software changes to IT systems on the aircraft. The Boeing 787, for example, has more than 280 LSAPs with more than 1400 instances, some of which require updating on a monthly basis. While the benefit of the new generation of e-aircraft is that these software updates can be distributed remotely through secure wireless connectivity, it will require an increased IT capability, including network connections to third-party software providers and integration of new applications, than that which is needed with legacy aircraft.

In particular, different airframe OEMs (original equipment manufacturers) have unique data models and cloud storage services for hosting their aircraft data and applications making it difficult for an airline with mixed fleet to get the full picture across their fleet without complex integration.

A common approach will cut risks and cost

Managing the different technologies and data exchange with aircraft across a route network and a mixed fleet is going to present airlines with significant challenges in executing their aircraft digitalization strategy. In addition there are likely to be multiple stakeholders with whom to engage and collaborate.

While there is not a single technology solution to solve the ‘nose-to-tail’ needs of connected aircraft at airports globally, there is a degree of commonality that makes it possible to design a set of connectivity and e-service capabilities that span the cockpit, cabin and aircraft maintenance, and which can be delivered through a single IT platform. Such an approach could address mixed fleets in a neutral and scalable way using industry standards, best practices and the well-established advantages of shared infrastructure.

Wide ranging benefits

A common IT platform approach provides a strong value proposition not only for airlines, but for the airframe OEMs, by delivering a number of benefits:

- Managing the different communications technologies required for data exchange with the aircraft, both on the ground and en-route, leveraging shared infrastructure, including VHF/VDL, satellite, wireless and Gatelink footprint, as well as 3G/4G and WAN connectivity.

- Providing a set of integrated application services, covering the cockpit, cabin and aircraft well-being, allowing airlines to securely and cost effectively manage content between aircraft systems or crew devices, and ground applications.

- The platform could standardize, process, filter and deliver the data flows to and from the aircraft based on the different needs of each stakeholder, whether an airline, airframe OEM, air traffic management or even supplier of charts and weather data for EFBs.

- Offer a clear way forward for airlines starting their aircraft digitalization journey in terms of cost effectiveness, flexibility, security, and scalability. An approach that can be ramped-up both globally and across a multi-fleet environment.

- A neutral industry platform would allow all OEMs to serve the needs of airlines with new value added services.

- Airlines and OEMs would no longer need to embark on complex individual IT projects, dealing with regulatory constraints, multiple aircraft types and different airports.

Cyber security will be critical

Connected aircraft will put the spotlight on the need for increased cyber security in aviation. Data integrity is essential, but there is concern that some next generation aircraft may have network vulnerabilities. In 2013, Boeing implemented additional security measures on its 777 series of aircraft to prevent onboard hacking of critical computer systems.

Each airline, aircraft manufacturer and OEM will need to ensure they eliminate the risk of uploading viruses or malware when they transfer data from back-end systems to the aircraft. There are already moves to mitigate the threat, with efforts to segregate the passenger, crew and maintenance networks, as well as deploy other isolation techniques already common on military aircraft. A major advantage of a common approach will be to ensure the highest security standards can be implemented across the global fleet and make oversight of that security far easier than dealing with hundreds of different airlines.

The bottom line

The introduction of new generation aircraft and retrofitting of older aircraft over the next decade provides a compelling value proposition for fully integrating them into the airline’s ground IT infrastructure. It will bring a step change in process efficiencies from routing to maintenance to turnaround and open the door for new value-added services that will become as critical for generating ancillary revenues as the airline website.

However, airlines are only just beginning to wake up to the full implications and potential of continuous data exchange with the aircraft in flight and on the ground. It requires significant cost considerations and changes to the processes and IT environment around the aircraft. Not least will be ensuring secure, reliable and affordable IP connectivity in-flight and at each touch point on a global route network.

De-risking these challenges can best be performed at the industry level through best practices and shared infrastructure. Those that successfully overcome the obstacles and execute their aircraft digitalization strategy will create competitive advantage by maximizing aircraft availability and improving the passenger experience.

Contributor’s Details

Mario Sabourin Sr. Product Manager EFB, SITA

Mario Sabourin is responsible for eliciting EFB-related business requirements, defining business models and service architecture, conducting joint innovation programs with customers and partners, product marketing and pricing, partnership management and other product management activities. Prior joining SITA, Mario held systems engineering and management positions in large global companies such as Motorola and Lockheed-Martin. He is a graduate holding B. Eng. Electrical, M. Eng. Electrical, and MBA in product management and corporate finance plus qualifications in project management (PMP), product management (NPDP), and business process improvement (Six Sigma Green Belt).

About the Company

SITA

SITA is the world’s leading specialist in air transport communications and IT solutions, delivering and managing business solutions for airlines, airports, GDS, governments and other customers over the world’s most extensive network, which forms the communications backbone of the global air transport industry.

To post a comment, please login or subscribe.