Articles

| Name | Author | |

|---|---|---|

| EASA crackdown on Aviation IT Systems | Sander de Bree, CEO, EXSYN Aviation Solutions | View article |

| Aircraft IT Survey: The Current and Future Aircraft Maintenance Software Market | John Hancock, Editor, Aircraft IT | View article |

| Case Study: TechOps Mexico implements paperless engineering management | Juan Ignacio Lopez, Planning and Productivity Manager, TechOps Mexico and Dr. Hugh Revie, Vice President, EmpowerMX | View article |

EASA crackdown on Aviation IT Systems

Author: Sander de Bree, CEO, EXSYN Aviation Solutions

Subscribe

EASA crackdown on Aviation IT systems

Sander de Bree, CEO, EXSYN Aviation Solutions explains how proposed regulatory changes will impact software and technology in MRO

This article will share some of the impending changes in EASA regulations of which readers might or might not be aware. It will also consider the impact this will have on IT systems in general that are used in maintenance and engineering operations.

A NEW APPROACH TO ENGINEERING IT

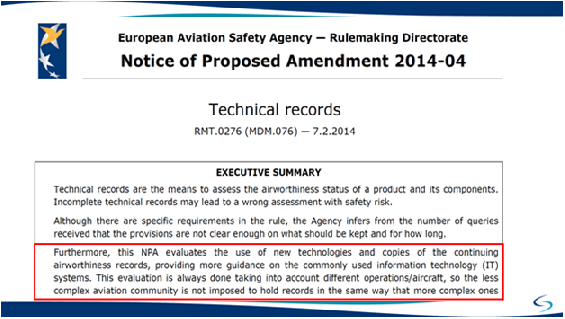

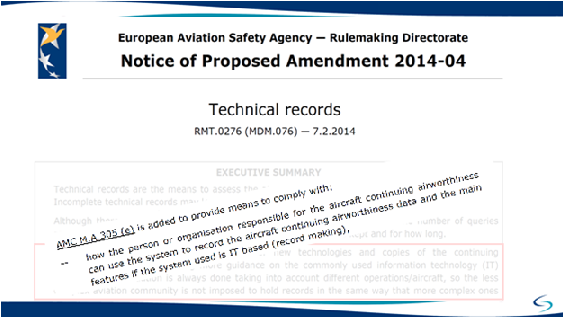

In 2014 EASA published a document with the number 0276 and the title ‘Notice of Proposed Amendment’ (NPA). The interesting part is that marked out in red in figure 2…

Figure 1

… and particularly on the second line where it says, “more guidance on the commonly used information technology (IT) systems.” At EXSYN we started to look a bit deeper into this forty-four page Notice of Proposed Amendment (NPA) where we also found the following sentence: (figure 2) “… how the person or organization responsible for the aircraft continuing airworthiness can use the system to record the aircraft continuing airworthiness data and the main features if the system used is IT based (record making),”. To sum up, this amendment focuses on the usage of the IT system, particularly on the back up of data and additionally on technical records for the aircraft and continuing airworthiness.

Figure 2

Before we go into detail, it should be highlighted that the Notice of Proposed Amendment was first introduced in 2014 (see above), and after publishing the document (in this case, at the beginning of 2017), the industry has three months to respond to it. This means that the time for raising objections is now closed; the matters that follow will become the reality and there’s nothing more to be done about it.

That 44-page document addresses some specific requirements and guidelines addressing how MRO / M&E systems handle some specific areas. It’s mostly data driven but there are also some functional aspects to it. For instance, it looks at Aircraft Logbook data and into how a system must demonstrate AD (Airworthiness Directive) compliance. It also looks at how a system must demonstrate compliance with regulations governing repairs and modifications and with scheduled maintenance. There’s a lot about how should a system used for record keeping by an airline demonstrate compliance with all the different aspects of continued airworthiness. Furthermore, there’s something in there about Counters and lifetime tracking of components and about how we could handle historic data as an airline or CAMO organization. Another area addressed is around the management of data corrections and protection against manipulation: there are even going to be regulations around the transfer of data between different MRO systems. Data integrity protection and, of course back-up control also feature in the new regime. There is not space here to address all the above so this article will focus on four very specific items that I believe will have the most impact on our work and on systems management in MRO/M&E IT.

- Counters and lifetime tracking of components.

- Handling of historic data.

- Data corrections and protection against manipulation.

- Data transfer between MRO / M&E systems.

COUNTERS AND LIFETIME TRACKING OF COMPONENTS.

What do the amended rules expect us to do? There are three main items to consider. For all components that have a time requirement on them, it will be necessary to have the full in-service history available in the airline’s system. For example, ‘time since new’ and ‘cycles since new’ of components can no longer be unknown in an airline’s MRO/M&E IT system even if the requirement only runs on calendar dates for instance. That can no longer be the case. So, if the airline is part of a pool agreement, it means that it will be necessary to have the in-service history of all the parts in the pool or that are installed on aircraft using the pool in the IT systems of each participating airline. That’s interesting because, currently if we are part of a pool, we only have that piece of the in-service history relevant since a particular component was installed on an aircraft in our own airline. We have no idea what happened before we used the component; we just have an EASA form 1 that says that when we remove it from the aircraft again, whatever happened before that remains unknown. This change will require all airlines likely to use a component to hold its in-service history which will mean a need for cooperation between pool parts providers and airlines.

What we can see emerging from this is something like centralized parts tracking. Not that long ago I was part of some conversations with vendors active in pool parts who are already seriously looking into how this can be managed, how to centralize this aspect of parts tracking because, from a pool provider’s perspective, it will mean that they need to have a complete in-service history when they send parts to an airline customer and vice-versa. That will be an interesting topic for the future which will also drive significant interface requirements between airlines and pool providers, between the systems used by airlines and between the systems used by pool providers.

Another item which is, perhaps to a lesser degree than the last one as a smaller item but nonetheless a nice example, is that for time controlled parts an IT system must indicate a component clearly with part and serial number. That makes sense but, for users of SAP for instance, SAP doesn’t know the combination part number/serial number (PN/SN), SAP knows the product number and that relates to a part and serial number. So, those working with SAP will face a problem in a couple of years. There will need to be a solution that clearly has the part number and the serial number as the main driver in a system and not the product ID. Over and above that the identified system must be able to track limits in calendar days, flight hours, flight cycles and landings.

THE HANDLING OF HISTORIC DATA

This is always a big topic when we are talking about data migration, MRO system implementations, etc. and what we have now is clear guidelines on how we should handle historic data as an airline. That says that an IT system used for airworthiness purposes will have to have a minimum of 24 months of aircraft operational historic data except for the aircraft Techlog where the minimum period will be 36 months even if the aircraft has come from another operator. That means that, as a minimum, an airline or aircraft operator needs to have two years of historic data of all airworthiness related aspects of an aircraft in the IT system. The one exception to that is, of course, where an aircraft is not yet two years old where the requirement is that all relevant data since manufacture date must available.

Below you will see a list of data that is going to be affected by that need to have two years’ information available. And, for readers who might have undertaken an MRO system implementation not very long ago, I’m sure at some point you will have asked how much historic data you needed to take across to the new system, i.e. take all historic data; leave all historic data in the old legacy system as back-up and implement the new system from scratch; or would it be best to take some data across? That question has now been answered; the new system will need to have at least two years of data. That means that if you have implemented an MRO system in the last two years and you decided not to take any historic data across to that system but to leave it as back-up on the legacy system, you’ll now need to go back to that system, take the historic data out and put it into the new MRO IT system. It also means that if you are in a current implementation you will need to plan to transfer two years of historic data into the new system. And it will also mean that if you’re going to plan to implement a new MRO system in the next two years you will need a minimum of two years’ historical data into your MRO IT system.

In terms of historical data, the types of items on which at least two years of historic data will need to go into the MRO system will include:

- Schedule maintenance compliance;

- Component removals & installations;

- AD compliance;

- SB, Modifications compliance;

- Structural Damages & repairs;

- Aircraft utilization;

- Aircraft Technical logbook entries (at least 3 years).

MANAGEMENT OF DATA CORRECTIONS AND PROTECTION AGAINST MANIPULATION

First of all, data must be traceable as to which user made what amendments or changes to airworthiness records; that’s logical. The second item is also obvious; that, for any change made, both the original and the changed entry must be available; that will be interesting. And third, there must be safeguards against unauthorized user access. What this means is it’s the end of using Excel in airworthiness management because it must be traceable which user made amendments and, for any change made, the original entry must be available: there isn’t an Excel spreadsheet that can do these things, i.e. retain the original value, the change value and who made amendments. Even if a way were devised to store all the different versions of Excel files that would be unwieldy; so, this will mean the end of Excel in airworthiness management.

It will also mean that the MRO database software solutions that are available will need to provide full login of any changes that are made. Some do have that facility, some have it partially and some don’t have it at all but they will all need to have that capability. So, if a user performs a certain action in the system, all of those changes, all of those tasks, all of those entries need to be stored and a log file needs to be kept of who made what specific changes on which specific airworthiness records. That will be quite a big task when it comes to tracking user activity, saving user actions, etc. in airworthiness management and a very big strain when it comes to tracking user actions in the current MRO software systems.

And the technical data held in this way must also be protected from technical obsolescence, i.e. available in a database that won’t become redundant over time.

AIRCRAFT AIRWORTHINESS DATA TRANSFER BETWEEN MRO / M&E SYSTEMS

Something of interest is the transfer of aircraft airworthiness data between MRO/M&E systems. The main topic here is that the airline software architecture in place needs to allow for the digital transfer of the aircraft continuing airworthiness records to another system. In other words, when you phase out an aircraft, receive and aircraft, or whatever, it will be necessary to have the possibility to digitally transfer all the airworthiness records to another system; not just print it to PDF and pass those over. Also, this will need to be in an industry-wide and worldwide format for data transfer. This is interesting because there is no such standard at present.

Looking at this topic in a little more detail, we see that OEM centralized management systems will need to be opened up in order to the export and transfer of data. That will mean that, for a lot of airlines, they’ll need to adopt a solution in their architecture that allows exporting and importing of all aircraft airworthiness data into and out of their systems. For readers involved in aircraft handbacks or aircraft phase-ins, I’m sure that you’re very familiar with those big boxes of aircraft records. That now needs to become digitally possible.

As for the industry-wide, worldwide format, there is no such format. There’s only something that is used at the moment that might grow into a standard which is more XML and SGML based on S1000D formatting and Spec2000. There will need to be an industry-wide, worldwide format but it isn’t here yet. We’ll look below at a similar initiative by IATA which could be quite an interesting addition to the discussion.

HOW ABOUT TIMELINES?

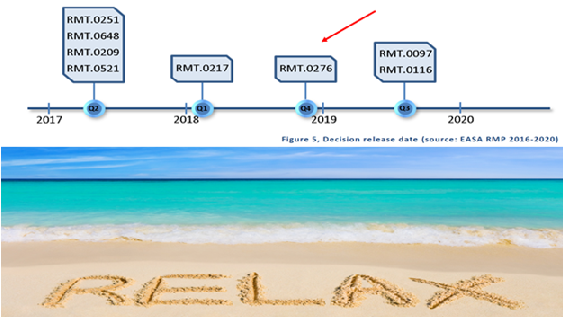

As you by now have realized, there are a lot of items that need to be addressed and you will wonder whether it’s necessary to get everything completed right now or is there still time? The roadmap in figure 3 shows that the RMT 0276, the one covered in this article, is scheduled to come into force in the fourth quarter (Q4) of 2019 which leaves little more than two years from now to prepare for this; and some of these changes will have quite a big impact so we might not wish to wait any longer than necessary. Come Q4 2019, the items covered above will not just be proposed amendments but, in effect, will be part of the EASA Part-M for continued airworthiness.

Figure 3

Although the illustration says ‘Relax’ I’m not sure whether we should be relaxed.

So, what can we do right now? Let’s start by looking at that RMT; download it and get familiar with the content of those rules and those regulation changes. The document can be found on EASA’s website at www.easa.europa.eu/rulemaking-tasks.rmt0276. The second step is that each airline will need to perform a Fit/Gap assessment identifying in which areas they should already be compliant with the new set of guidelines and in which areas there is work to be done. From there, a setup will need to be implemented and plan of approach established for each airline.

SUMMARY

By Q4 2019, EASA will implement new regulations for technical records specifically aimed at providing guidelines for IT systems used for airworthiness management purposes:

- It will impact functional requirements but will mostly impact data requirements;

- The days of Excel in airworthiness are numbered, so be sure to be ready for it;

- Fit / Gap analyses need to be made by airlines to ensure compliance and or how to reach compliance by the fourth quarter of 2019;

- Cross industry action will be required to address the issue of component lifetime values and aircraft data transfer, particularly when it comes to the pool parts that are used in the industry and, of course, the continuous cycle of aircraft hand-backs, aircraft phase-ins, etc.;

- Now it’s T – 2 years. Although that might seem some way in the future, it will come faster than anticipated.

A small bonus

There is a small bonus in some of the other things that are happening in the background but that relate to the subject of this article. EASA will soon be publishing its data security NPA for EFBs and ETLs and there will be some guidelines on that also around data security. There will be something around weight and balance of aircraft and aircraft systems anticipated in the first quarter 2018 and, from IATA there will be an initiative (mentioned above) which will pretty much tie into the aircraft data transfer requirements, i.e. the industry worldwide standard that is not yet available, as part of IATA’s digital paperless maintenance project but that isn’t due to report back until 2020, after the new regulation covered in this article will have become effective.

Contributor’s Details

SANDER DE BREE

SANDER DE BREESander de Bree is founder and CEO of EXSYN Aviation Solutions; focusing on engineering and technical management solutions for aviation and heavily specialized in the field of IT systems for aircraft maintenance. Next to implementing the overall strategy he oversees all operational activities and actively participates in R&D projects within the company. Sander holds a degree in aeronautical engineering with a specialization in aviation regulations and has a background in business administration. He is a member of the Royal Dutch society of engineers (KIVI NIRIA) and associate to the society’s departments of aerospace engineering and information technology.

EXSYN AVIATION SOLUTIONS

EXSYN AVIATION SOLUTIONS EXSYN provides aviation IT solutions with one important mission: to develop reliable, simple, and user-friendly software solutions and digital technology so that the aviation industry benefits more from digital possibilities. EXSYN’ s aviation solution platform focuses on data processing, data analytics, data storage as well as related consulting services for Airline Maintenance & Engineering departments. The firm has a broad expertise and a thorough understanding of all the high safety levels to provide clients with a service meeting the required standards and within the timeframe demanded.

Comments (0)

There are currently no comments about this article.

To post a comment, please login or subscribe.