Articles

| Name | Author | |

|---|---|---|

| Column – How I see IT | Michael Wm. Denis | View article |

| Also a business process – Air Works Case Study | Ravinder Pal Singh (Ravi), CTO and CIO, Air Works | View article |

| Lost in Translation? – Data Warehousing | Tim Alden, Commercial Director, Rusada | View article |

| Case Study: Facing up to the IT challenge of offshore helicopter operations | Brian P. McDonald, Principal & Managing Director, SFS Aviation Thailand | View article |

| Mobility Deep Dive – Future Mobility Platforms | Paul Saunders, Global Product Manager, Flatirons Solutions | View article |

Case Study: Facing up to the IT challenge of offshore helicopter operations

Author: Brian P. McDonald, Principal & Managing Director, SFS Aviation Thailand

SubscribeFacing up to the IT challenge of offshore helicopter operations

It was important, says Brian P. McDonald Principal & Managing Director of SFS Aviation Thailand, to select an MRO solution that could address all of the business’s needs.

Thai helicopter business, SFS Aviation, founded in 1990, now employs 150 staff, including 48 pilots, 52 engineers and 50 in support and administration. And we use the latest generation aircraft to operate in support of offshore oil and gas customers’ installations. The fleet comprises four AW139 Helicopters, three S-76C+ Helicopters and two BK117. Corporately, the business is part of a $350 million group with interests in fuel, lubricants, chemicals, real estate, marine logistics and Aviation. In short, SFS Aviation has strong ownership which, in turn, supports a company commitment to quality and safety.

Thai helicopter business, SFS Aviation, founded in 1990, now employs 150 staff, including 48 pilots, 52 engineers and 50 in support and administration. And we use the latest generation aircraft to operate in support of offshore oil and gas customers’ installations. The fleet comprises four AW139 Helicopters, three S-76C+ Helicopters and two BK117. Corporately, the business is part of a $350 million group with interests in fuel, lubricants, chemicals, real estate, marine logistics and Aviation. In short, SFS Aviation has strong ownership which, in turn, supports a company commitment to quality and safety.

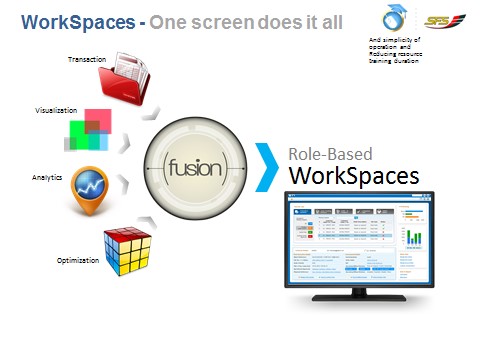

All aspects of the business are managed and operated by a process model using an integrated ERP system which achieves our objectives by installing controls and barriers to manage human error. SFS Aviation, in line with offshore helicopter operators worldwide, is embracing SMS and process driven management tools. We are also looking to the airline lesson wherein all aspects of a flight are carried out in the same manner with checklists, a process, a stabilized approach, clearly defined criteria and parameters for all personnel to follow. Some examples of this include…

- Restricting the issue of purchase orders to ‘approved vendors’ only – a QMS (quality management system) requirement.

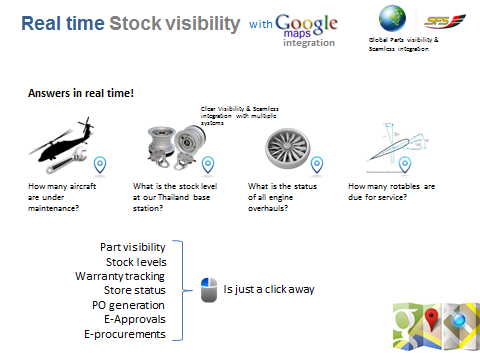

- Setting minimum/maximum inventory levels with an automatic purchase order being issued when stock levels on certain items reach minimum agreed levels.

- An alert notification when critical components or maintenance checks are approaching, with thresholds set at company determined levels based on current utilization, etc.

- Assistance in the management of training schedules and personnel rosters through integration with HR module, i.e. alerts are triggered when CRM-Simulator slots are becoming due.

- Analysis of data through input of information such as HUMS (health and usage monitoring system), HOMP (helicopter operations monitoring program) and flight data information. Allows management to track performance and reliability of aircraft, personnel, parts etc.

We also work to a number of general standards and deploy systems and equipment applicable to the type of operations in which we are engaged.

- Minimum OGP (oil & gas producers) standards.

- Aircraft meet the latest FAR (Federal Aviation Regulations) with enhanced handling and glass cockpit avionics and displays.

- Our pilots are subject to full flight simulator training and have access to cockpit resource management.

- QA (quality assurance) and SMS systems are applicable throughout operations.

- We use an aircraft and engine HUMS.

- HOMP, FOQA (flight operations quality assurance) and FDM (flight data monitoring) all offer full downloads and analysis.

- We operate aircraft with Performance Class 1/2e having the full ability to climb with full payload from a Heli-Deck in the event of one engine failure.

- We also deploy EGPWS (enhanced ground proximity warning system) and TCAS (traffic alert and collision avoidance system).

Critical IT challenges

So how do we plan to address and tackle these critical IT challenges?

The solutions that we have implemented

Flexibility and mobility

A solution matched to our needs

There was an entire gamut of solutions available from which we have tailor-made our system by selecting relevant modules for immediate use while retaining the option to add more should the need arise in the future. This is the solution that addresses the last of the critical IT challenges we discussed earlier, seamless integration with existing systems and key functions such as HR, procurement etc. The aviation solution we chose is also able to take over our entire business and offer an end to end business solution, including human capital management, and finance and accounting.

Brian has 48 years general aviation experience and extensive helicopter maintenance experience in senior roles with various helicopter companies in Australasia. He holds private pilot licenses for both fixed and rotary wing aircraft. Having lived and worked in Asia for 30 years, Brian has extensive Asian experience, including General Manager, Hawker Pacific SEA and CEO of Helicopters (NZ) Ltd. He also has extensive contacts with operators and helicopter OEM’s and offers consultancy services to the general aviation sector in Asia.

Ramco

Ramco Aviation Suite manages the entire business of aircraft maintenance covering engineering support, inventory and procurement, maintenance, sales and MRO contract management, compliance, quality, and operations. The company also offers an Off-Line Field Maintenance module targeted at organizations having remote aircraft operations with no internet connectivity. Ramco Aviation Suite is modular and specific functions such as Reliability Management can also be deployed as a standalone best of breed solution alongside existing systems.

Comments (0)

There are currently no comments about this article.

To post a comment, please login or subscribe.