Articles

| Name | Author | |

|---|---|---|

| Fuel Efficiency Solutions | Wayne Beardsley, Consultant - Fuel Efficiency Solution, Rolls-Royce | View article |

| Putting the customer first | Alexander Tatidis, Sales Representative/Assistant Sales Manager, Flygprestanda | View article |

| Case Study: ETL: the move from paper – part 1 | Cameron Hood, CEO, NVable, Rob Woods, Head of Engineering, Air Arabia Maroc, and Dave Cooper, Line Maintenance Manager, British Airways Cityflyer | View article |

| Column: the World according to IT and me.. Sturgeon’s Law | Paul Saunders, Solution Manager, Flatirons Solutions | View article |

Fuel Efficiency Solutions

Author: Wayne Beardsley, Consultant - Fuel Efficiency Solution, Rolls-Royce

SubscribeFuel Efficiency Solutions

Wayne Beardsley, Consultant – Fuel Efficiency Solution at Rolls-Royce, shares his views on the key components in airline operational efficiencies

ROLLS-ROYCE

Rolls-Royce’s involvement in advanced data analytics goes back to 1999. Today, around 70% of our digital services are focused on Aerospace, supporting the TotalCare® Service Solutions in the areas of Maintenance, Availability, Efficiency and Asset Value. Our digital services, however, underpin Rolls-Royce’s offering in all its markets, with our expertise in delivering data insight and informed decisions in the areas of Equipment Health Management; Fuel Efficiency; and Quality, Safety, and Risk Management.

In the aerospace sector, we analyze billions of data points on-board per flight for more than 1,300 customers worldwide. Every month, we monitor and manage the fuel consumption of 6,000 flights, using our advanced technology and expert consultancy. We were also one of the first companies to provide a fuel management system, processing huge quantities of data and generate value from it, whether this is for government agencies in defense, commercial and cargo airlines, or aircraft operators.

MUCH MORE THAN SAVING FUEL

Fuel management should provide deeper insight to and understanding of an airline’s fuel consumption and provide actionable information to help reduce cost, the key word. It’s not about saving fuel; it’s about saving cost; and sometimes, as readers will be aware, a little bit more fuel has to be burned to save cost. The combination of technology and expert consultancy helps achieve that objective efficiently. We provide an ‘actual versus plan’ scenario: the flight planning system will give the best possible plan but users also need to know what actually happened on a particular flight. A fuel efficiency system will report what actually happened which can, in turn, be fed back into the planning tool.

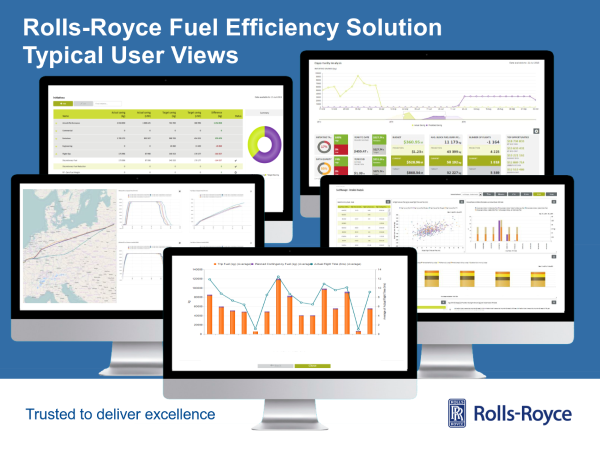

It’s also important to communicate this information to the crews, the engineering department, the ground management and the senior management. For instance, the Rolls-Royce system with which I work provides a wide range of dashboards and charts to help communication and effect change. And, once change has been introduced, it’s important to be able to monitor initiatives so that, when an airline launches a new initiative, it can be maintained through the cycle and continued – avoiding bad habits returning into the airline.

It’s important that vendors and consultants in this market keep up with the latest requirements and opportunities. Rolls-Royce’s digital services are subject to continual development, and we have an exciting roadmap for this year and beyond, with major developments enabled by new technology, including open platforms, supporting the integration of wider sets of data, at the same time enabling further collaboration, and delivering even richer insights to our customers, to maximize efficiency across their fleet and ultimately their operations.

THE PROCESS TO FUEL EFFICIENCY

Using our own service as an example, a typical engagement with a customer would start with a visit from an expert consultant, meeting the customers on site to examine their current fuel efficiency initiatives and program. They’ll look at all the data sources available; from flight planning systems, operations control systems, load control systems… and how best to integrate all that data into the solution. The data will be cleansed with all the checks and balances that are required on the data completed. The consultant will also give confidence to the data; validate how good it is and make sure that it represents a good picture of the airline’s operation. All of this feeds into the initiatives that the airline will be completing. The system can report on performance at whatever level is required (from individual aircraft in the fleet or fleets within the airline, or even down to performance for each pilot) in the appropriate format specific to the recipients. It all helps with forecasting fuel savings for the rest of the year and budgeting for future fuel usage and costs.

UNDERSTANDING AND MANAGING COSTS

Of course, airline operations are not only about fuel, and it’s important to understand all the cost drivers and cost management factors in an airline…

- Traditional and extended fuel initiatives – most airlines will have some program(s) already in place;

- Air traffic management;

- Tail optimization – putting the best aircraft onto the best route;

- Engine wash optimization – tailoring the ‘wash’ program to the experience with each tail and fleet, as opposed to just following standard OEM recommendations;

- Derate analysis: for instance, understanding that, if reduced take-off thrust or climb thrust is used to reduce engineering costs, there is sometimes a fuel penalty for that – the best combination of cost and most efficient way of flying is to be taken into consideration;

- Equipment health management and lifing, making sure that the airline is getting the best results from each engine.

COMMUNICATING AND DISPLAYING THE INFORMATION

Typical user views would include a selection of tables, bar charts, graphs (see figure 1 below)

Data – various sources; different uses

Airlines are discovering that QAR (Quick Access Recorder) data or FDM (Flight Data Monitoring) data is not only critical for monitoring safety but is also a fantastic tool for managing fuel. Our tool, for instance, is able to take and use an airline’s QAR data, whether it is processed data from the flight safety department or it is raw data that can be processed at three different levels…

- Summary parameters – available for charting alongside all other non-QAR parameters ingested via data integration;

- Actual route information – mapped at one minute intervals via the Flight Analysis pages;

- Original QAR parameters – available at original frequency via chart drill down to the Flight Data Module.

With QAR data, there is even more information on individual flights in order to identify and measure actual fuel savings, not estimated figures. The QAR data lets users look at a range of factors that impact fuel and cost: the weather on arrival, the arrival runway used, the distance to stand… right down to the individual flight level.

Contingency fuel

Another area on which airlines are concentrating is contingency fuel – the extra fuel put on a flight plan to cover unforeseen events and ensure safe operation come what may. Contingency fuel generally represents five per cent of the overall trip fuel, but airlines will be interested in ways to reduce this figure because, on long-haul flights, five per cent can amount to thousands of kilos. If everything goes to plan, as well as being an extra cost, it is unnecessary fuel weight being carried on a flight which will, itself, require extra fuel burn. So airlines have an interest in reducing contingency fuel in a safe and efficient way; taking, say, five per cent down to three per cent or, with re-clearance, even lower.

Also a statistical contingency fuel (SCF) calculation can reduce the amount of contingency fuel needed. Statistical contingency fuel is another level, where using a fuel efficiency solution, it is possible to track historic fuel contingency carried and how much of that was actually required. This can be managed by normalizing the data by sector length, zero fuel weight and refining it to that operation route by route to reduce the statistical contingency.

Extra fuel loaded by the pilot’s decision is known as discretionary fuel and is a further consideration. This is not controlled in the usual way because the pilot is able to determine what he believes to be appropriate for his mission. However, it’s important that discretionary fuel is monitored and tracked by pilot or by fleet, to make sure that it’s no more than necessary. In particular, if contingency fuel is reduced without first securing pilot buy-in, pilots will tend to increase discretionary fuel uplift which counterbalances any fuel savings.

Reduced engine taxi

Another area of interest is reduced engine taxi, whether –in or –out, which is different for a two engine aircraft as opposed to a four engine aircraft and again, Rolls-Royce’s tool can track that by airport, by fleet, by time of day, day and date or how often reduced engine taxi is completed. And that data can be filtered to only represent airports where reduced engine taxi is possible.

Communication is the key to acceptance

In all of this, it’s highly important to communicate changes with the crew in order to get the buy-in of the pilots; for instance, to make sure that they don’t carry more discretionary fuel when the contingency has been reduced. A fuel management system can provide credible material to ensure optimized communication. Also, when approval is needed from the authorities to reduce contingency policy, a fuel management system will produce the statistics to support the case. But it’s important not to take too much account of the variances, i.e. don’t take one-off events into consideration when reducing contingency fuel. And, it’s also important to have an accurate flight plan in the first place (modern tools make this possible) and to be able to show pilots that flight time and fuel burn are within a nice scatter. Keeping that scatter down gives pilots the confidence to not carry discretionary fuel

SUMMARY

Fuel efficiency is an important element in the modern airline management mix but, in order for it to be conducted effectively and to meet the various demands that impinge upon fuel usage, airlines need a powerful and comprehensive data based solution and a trusted partner, so they understand what to do, how to do it, are able to track progress and ensure that everybody who can influence fuel efficiency within the business is engaged and supplied with the relevant insight.

Contributor’s Details

sm.jpg) Wayne Beardsley

Wayne Beardsley

With 30 years’ experience in the aviation industry, Wayne is now a Fuel Consultant with Rolls-Royce and has a lot of expertise in flight operations, ground operations. He previously worked with British Midland Airways where, in a fourteen year career he was flight operations support manager implementing a leading-edge flight planning system. Responsible for Aircraft Performance, W+B and Technical publications, he worked as part of the Lufthansa group before integrating the bmi fleet within British Airways.

About Rolls-Royce Holdings plc

About Rolls-Royce Holdings plc

The company provides safety critical controls and asset intelligence solutions for industrial power, marine, civil and military aerospace. It produces engine control software, electronic engine controls (EEC), fuel metering units (FMU), fuel pumps and engine actuators for a large number of common commercial and military aircraft. Together these parts comprise the control system for a jet engine, responsible for delivering the correct amount of fuel and maintaining engine safety.

Comments (0)

There are currently no comments about this article.

To post a comment, please login or subscribe.