Articles

| Name | Author | |

|---|---|---|

| Case Study: Fuel savings at Transavia | Thomas Aliguen, Fuel Manager, Transavia, and Alex Feray, CEO at OpenAirlines | View article |

| Column: The World according to IT and me.. Pithy Bites | Paul Saunders, Solution Manager, Flatirons Solutions | View article |

| The Digital Revolution: Connectivity and Mobility in Operations at Air Canada | Steve Bogie, Senior Director, Operations IT, Air Canada | View article |

| Go Direct with Free Route Airspace | Uwe Nitsche, Co-founder and CEO, RocketRoute | View article |

Case Study: Fuel savings at Transavia

Author: Thomas Aliguen, Fuel Manager, Transavia, and Alex Feray, CEO at OpenAirlines

SubscribeFuel savings at Transavia

Thomas Aliguen, Fuel Manager at Transavia and Alex Feray, CEO at OpenAirlines explain how Transavia engaged pilots in their fuel conservation program using sophisticated software tools

Before launching into the case study proper, it will be useful to tell readers something about the two businesses most involved, Transavia France and Open Airlines.

Transavia

Transavia is the low cost carrier and subsidiary of Air France KLM Group with two operating divisions in Transavia Netherlands and Transavia France. All aircraft in the fleet are Boeing 737 of which the Netherlands division has a fleet of 36 aircraft whilst the French fleet includes 21 aircraft. Both fleets are growing so there is a strong and increasing incentive for the airline to implement a fuel efficiency and fuel saving program for its operations serving about 100 destinations mainly in Europe and across the Mediterranean.

OpenAirlines

OpenAirlines is a software provider in the field of optimizing flight operations (including crew optimization, fleet optimization and, most importantly, fuel optimization) with a range of airline types from traditional and legacy operators to regional airlines and low cost airlines.

Clean Sky

This case study covers the fuel management project for Transavia France with OpenAirlines which started in 2009 spurred on by a major project called ‘Clean Sky’ – the largest R&D program worldwide on the future of an environmentally-friendly aviation Industry with some €1.6 billion invested in the project by major stakeholders including Airbus, Rolls-Royce, Safran and the EU itself to develop more efficient and greener aircraft. In some subject areas, the program opened up for bids from other potential partners and the first project in this included several airlines (including Transavia France), universities, OEMs and software producers. The project analyzed more than 10,000 flights from five airlines covering most models from the Airbus and Boeing fleets, ATRs, etc. to generate information for Thales leading FMS research within Clean Sky. Also by doing that, some further information was discovered with pilot interviews and the establishment of performance models with OEMs. It was from this that SkyBreathe was developed. We also undertook some analysis of airspace constraints. So that was how OpenAirlines and Transavia France started working together on this project in 2009.

Building the new system

While talking with pilots some interesting discoveries emerged, such as that while Transavia France management believed that idle reverse thrust was being used, in line with instructions, on 80% of the occasions when it could be applied, in fact the real figure for idle reverse thrust use in 2010 was only 44%. While each occasion when it’s used might only save 15kg of fuel, if that is multiplied up by the number of times when it could be used, the cumulative saving will be considerable. Armed with that information, Transavia France and OpenAirlines could show pilots what savings they could contribute with just this one fuel saving process and the pilots responded brilliantly so that idle reverse thrust use at Paris Orly increased to 80% in 2011 and to 93% in 2012, saving $15,000 per aircraft, per year. This was something that Transavia France had already identified in their best practice but had not previously been monitoring.

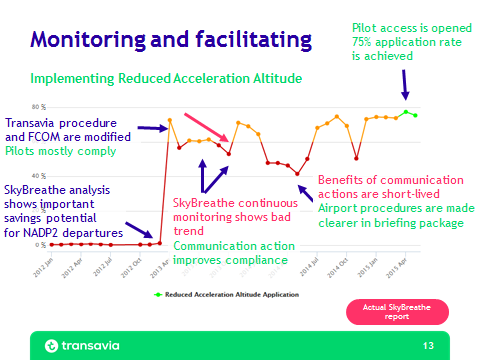

That experience, in turn, suggested that this type of analysis should be done automatically using a fully automated system every day on all flights. That was how SkyBreathe came to be developed and, a couple of years later, implemented at Transavia France. The implementation took three months and included setting up a fully automated connection taking data from Flight Data Monitoring (FDM), the original flight plan (OFP) and the Operations Control Centre (OCC). So, the data import method and links were established but more important still was the computation engine, undertaking the models’ calculations to determine actual savings based on performance. This is a very important component when engaging pilots in the process because, if they can’t be shown fuel estimates based on an actual performance model, then they won’t accept what they are being told and they would be right to challenge it.

From there, the system automatically produces metrics, KPIs (key performance indicators) and dashboards to which users can refer using a web browser on, say, an iPad. So, having reached the end of the first stage, all of this information is now produced automatically by SkyBreathe. In addition, OpenAirlines works with Transavia France on a monthly basis offering fuel consulting where engineers review the data, investigate it and prepare some slides for the fuel plan to explain precisely where the airline can make progress on fuel management measures for each airport served. In addition to this routine monitoring, there will also be one-off tasks from time to time as the airline identifies other areas where a knowledge-based approach to fuel efficiency and CO2 management could be applied.

So that was the first step towards implementing a better fuel management program. The next step was to involve pilots in the process which is key to ensuring that flight ops best practices are used; and that was a lesson in itself.

Informing and training the pilots

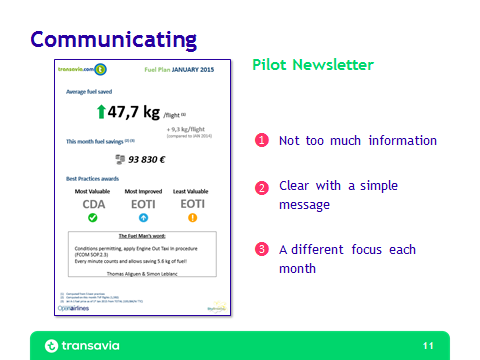

One efficient way to manage the fuel saving program is with training for pilots. So, every year, Transavia France reminds pilots of fuel procedures policy using reports and the previous year’s results to illustrate the points while, at the same time, introducing new procedures if needed and emphasizing the importance of fuel saving. Very detailed illustrations and graphs are used from SkyBreathe based on the flight data recorder. Also, in addition to the training, Transavia France sends pilots a newsletter: the aim of this monthly communication is to provide clear information, succinctly delivered about the previous month’s fuel management results, application rates for best practice and some reminders about how pilots can contribute to the airline’s overall fuel management program.

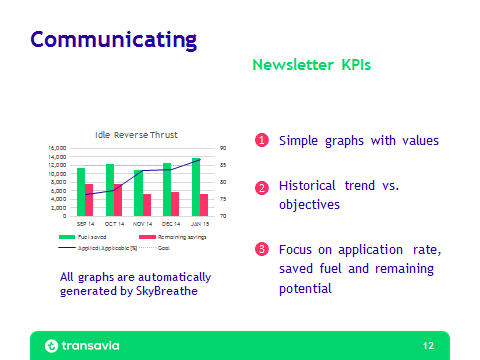

The example illustrated above includes statistics generated from monitoring fuel saving procedures as well as some information about a best practice procedure: in the illustrated case that is, “Conditions permitting, apply Engine Out Taxi in procedure (FCOM S.O.P.2.3). Every minute counts and allows [a] saving of 5.6 kg of fuel!” It’s a short but clear message so as not to cloud the issue with complexity or a lack of clarity. However, for flight crew who want to read more on best practices for different airports and how fuel saving could be improved; the newsletter also includes historical trends against the objectives in respect of each ‘best practice’.

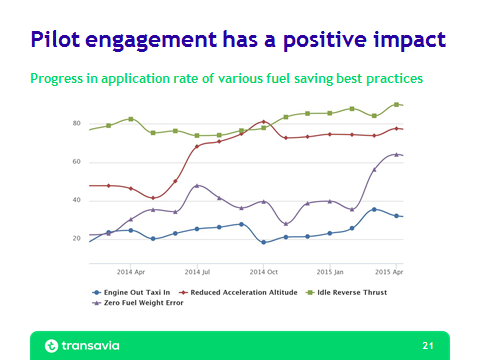

For instance, one screen (see above) deals with ‘Idle Reverse Thrust’ showing one of the graphs that are automatically generated by SkyBreathe and covering the period September 2014 to January 2015. It shows an increasing trend to apply best practice procedures in this which, in turn, produces useful benefits.

Involving pilots in a positive manner

In all of this, the key to success was a combination of the power of continual monitoring and analysis coupled with pilot acceptance of a new system and ways of doing things. The first prerequisite for pilot acceptance was for the system to be accepted as a good thing for flight crew so Transavia France invested time discussing the new system with pilots and their unions and ensuring that the system was open access but with a privacy policy. In this way it was possible to ensure that pilots did not regard the new arrangement as a procedure with which management could be always looking over their shoulders but rather as a tool for pilots to use, to improve their contribution to the overall objectives of the business. The second prerequisite was that the system should produce accurate computations that matched pilots’ own flight experience so that they could be confident of the output. In this way, they are able to see what the system has identified as best practice for the prevailing conditions and to measure what that practice would save if wholly adhered to.

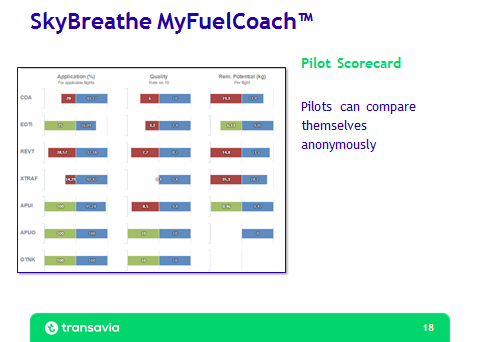

The system also enables pilots to compare themselves with others in the fleet but retaining anonymity. From the screen (below) pilots can see their own best practice application rates compared to their colleagues.

Since making SkyBreathe access available for pilots, Transavia France has recorded an increase in the number of occasions when pilots apply the appropriate best practice for the various fuel saving methods as the chart below makes clear.

As far as the feelings of pilots are concerned and after a few months of using the new system, most pilots appreciate the tool with its personal and detailed post-flight reports based on the monitored facts to which they can relate. They are finding the process very easy to use and the detailed data collection is not an issue once they have realized that it delivers a tool to help them rather than to monitor their work. It has been a positive help for pilots to manage fuel consumption more efficiently and the comparison to other pilots’ performance provides a positive motivation for each individual to consider what others are doing and to improve their own performance. As an indication of the tool’s acceptance by pilots, among the 200 pilots at Transavia France, most days 100 or more of them will access their reports.

Conclusion

The objective of this project was to save fuel and, in that, the program has been demonstrably successful and to an increasing degree since adopting the fuel management system in 2013. In fact, in 2014, Transavia France saved 800 tons of fuel which represents about €1 million and a reduction in CO2 emissions equal to 2,520 tons. All of this has been achieved with a strong system to monitor performance in the key areas for fuel saving and to inform new fuel efficiency related best practices. The system was supported by a program to involve pilots in the process, raise their awareness and supply them with the tools they need to complete their part towards the fuel efficiency objective.

Thomas Aliguen

Thomas Aliguen is a Flight Operations Engineer at Transavia France. He began at the Quality Department in 2012 as an intern before finishing a master degree in aeronautical and aerospace engineering. In 2013 he joined the Flight Safety Department for six months before going to the Flight Operations Department.

He mainly works on the operational documentation and manages the development of new projects such as fuel efficiency, or regulation studies.

Transavia France

Transavia France is a French low-cost airline and a wholly owned subsidiary of Air France-KLM. It began operations in May 2007, operating scheduled and charter flights and is now positioned as part of Air France-KLM’s joint low-cost brand. The airline flies to both leisure and metropolitan destinations with a fleet that comprises 20 Boeing 737-800 with an average fleet age of less than six years.

Alexandre Feray

Alexandre Feray is CEO of OpenAirlines. He has 23 years’ Software and Airline Industry experience and holds an MSc in Engineering and IT. He managed complex IT systems at Alcatel Lucent and at Air France. In 2006, he founded OpenAirlines, providing consulting and software solutions to reduce the costs of airline operations. Alexandre is also in charge of the Advanced IT Systems Architecture syllabus (including Big Data and Cloud architectures) at Ecole Centrale Paris.

OpenAirlines

OpenAirlines was founded in 2006 by former airline operations top executives with the vision to bring innovation to the industry. The business has a commitment to approach customers with great listening skills and professionalism to deliver results and added value. By combining unique business and IT skills, OpenAirlines proposes innovative solutions to reduce costs and bring a competitive advantage to customers. SkyBreathe® Fuel Efficiency, based on Clean Sky research, is one of a suite of solutions designed to make flight operations more efficient and profitable.

Comments (0)

There are currently no comments about this article.

To post a comment, please login or subscribe.