Articles

| Name | Author | |

|---|---|---|

| Case Study: MRO IT as a key enabler of your vision | Mesfin Tasew, Chief Operating Officer, Ethiopian Airlines | View article |

| Insight into the creation of the new manage/m® WebSuite 2.0 | Dr. Falk Kalus, Director of the manage/m® department, Lufthansa Technik Maintenance International, and Timo Herster, Project Manager, Internet Based MRO, Lufthansa Technik Maintenance International | View article |

| Column – Why pay billions for smart aircraft only to plug them into dumb IT? | Michael Wm. Denis | View article |

| Case Study: Point of Maintenance Acquittal | Michael Killeen, Project Marlin Project Manager, Qantas Engineering | View article |

| Inventory Management – Taming the Chaos | Saravanan Rajarajan, Consultant – Aviation Practice, Ramco Systems | View article |

Inventory Management – Taming the Chaos

Author: Saravanan Rajarajan, Consultant – Aviation Practice, Ramco Systems

SubscribeAs global input costs continue to rise, airlines are under constant pressure to maximize profits and reduce costs. To minimize the locking up of working capital, airlines adopt several cost cutting measures, including stringent control of inventory, right from aircraft induction to phase out. Material Planners play a key role in effecting this objective. Saravanan Rajarajan, Consultant – Aviation Practice at Ramco Systems has a close and detailed look at aircraft spare parts planning

Executive summary

Every on-time take-off for an aircraft is the result of various functions within an airline such as operations, ground handling, maintenance, materials etc. working seamlessly together. A closer look at the materials’ function reveals the complexity involved with meeting the service levels for maintenance. At the same time, they also face the challenge of being answerable to top management on the issue of inventory cost.

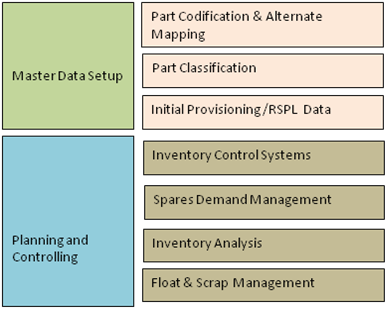

Without Material Planners to ensure the availability of the right part, in the right quantity, at the right place, in the right condition, with the right quality and with the right certification, no single solution or single approach will be able to meet the objective. The following key areas play a vital role in achieving the desired objective of meeting service levels:

- Part codification and alternatives;

- Part classification;

- IP (initial provisioning) /RSPL (recommended spare parts list) data;

- Inventory control systems;

- Spares demand management;

- Inventory analysis;

- Float and scrap management.

Aircraft spares – unique challenges

Spare Parts Management plays a vital role in any asset intensive organization such as refineries, fertilizers, power plants and airlines. One of the unique challenges for airline operations is that every key asset such as aircraft, crew, inventory, spares etc. is on the move. The biggest question in airlines is not only how many spares to hold but also where to hold them.

%20Figs%201%20&%202..jpg)

Fig 1: Total Inventory Value and Reporting Airlines Fig 2: Average Inventory Value per Airline and per Aircraft

IATA: Airlines Maintenance Cost Executive Summary – based on all MCTF (Maintenance cost Task Force) airlines reporting data between FY 2007-2010

Typically, airlines spend 20 to 25 per cent of direct maintenance expenditure on the cost of the spare parts used in maintenance. Owing to the volatility of prices with aviation parts, vendors change the prices regularly and these changes are often decided based on the lead time demanded and the proprietary nature of the part. The escalation of prices can be seen in Fig. 2, as the average inventory value per aircraft is on the rise. Airline material planners are under pressure to cut costs by reducing inventory but at the same time to ensure that aircraft are not grounded due to the non-availability of spare parts, thereby losing revenue.

Material planning – focus areas

The adage, ‘Every day is not the same day’ is especially apt for materials planners. Their objective is to ensure the availability of the correct part number, in the right quantity, at the right place; so a focus on a single area will not yield the desired results. A holistic approach to key focus areas (from managing the master set-up to various other key areas in planning and controlling) has resulted in overall efficiency in terms of meeting service levels and cost control.

Fig. 3: Typical material planning areas / IT modules to be focused and managed

Part codification and alternate mapping

Although a basic step, any error at this point would lead to considerable inefficiency in the downstream process. Typically, organizations follow either the Manufacturer Part Number or an internal company-assigned Part Number to track and manage spares. Tracking with the Manufacturer Part Number has considerable benefits, especially when ordering the part, sending items on repair, and referring to the AMM, CMM, MPD or IPC (Aircraft Maintenance Manual, Component Maintenance Manual, Maintenance Planning Document or Illustrated Parts Catalog).

A few part numbers have a differing nomenclatures and are completely different when they are supplied from two different manufacturers. In such cases, a part record has to be created along with the manufacturer’s code. This will help in downstream planning and maintenance functions and also help specify the intended part number and nomenclature.

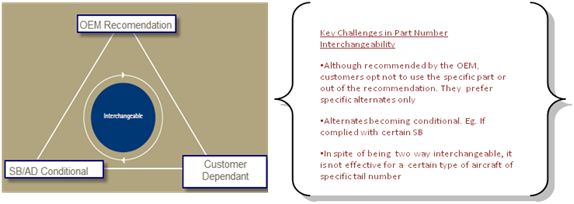

Another important aspect while setting up the part number is mapping the relevant alternate parts and interchangeable (INC) relationship as specified in IPC/RSPL: 1 – one way interchangeable; 2 – two way interchangeable; 3 – not interchangeable; 4 – interchangeable as a complete set only; 5 – conditionally interchangeable; 6 – parts re-identification.

Setting up of interchangeable mapping will automate the process of picking the alternate part when the maintenance requested part number is not available, thereby reducing considerable time in spares issue.

Fig 4: Interchangeability

Parts classification

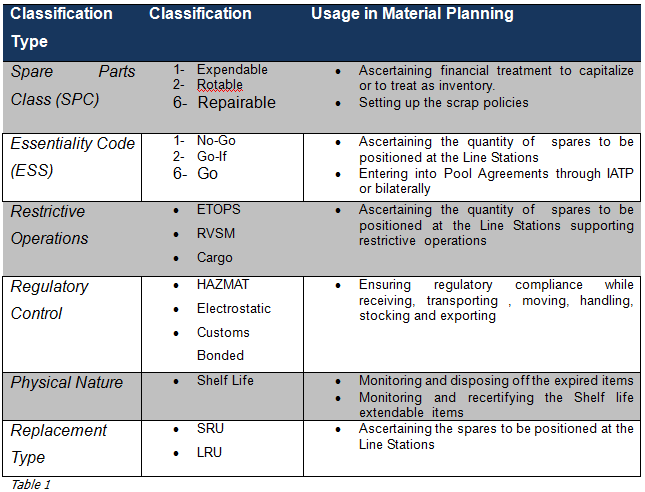

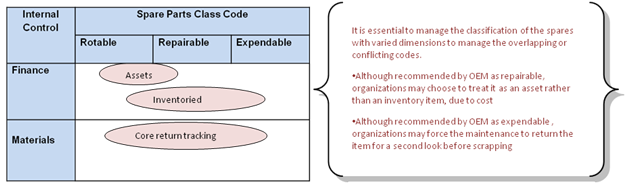

Agencies such as the OEM, suppliers, Customs, IATA, etc. classify parts for specific purposes. Internally, the organization further classifies the parts for financial and operational purposes. Managing these various classifications helps the various functions to operate seamlessly, besides integrating and aiding in automation and reporting. For example:

- ESS-No Go item should be prioritized in Internal Repair and expedited in External Repair;

- There needs to be a periodic automatic expiry report for shelf life controlled parts;

- There need to be enforced fixed location in warehouse to separately keep Electrostatic and Hazmat items.

Fig 5: Parts classification

Recommended spare parts list (RSPL) and initial provisioning (IP) data

Once it was common to estimate the spares that would have to be procured for the entire life of an aircraft along with the aircraft itself, with the cost of spares ranging from 15-20% of the aircraft cost. However, airlines now provide and procure in phases, keeping in mind the need for maintenance and the experience of operators in actual usage.

Key information available in the RSPL and IP has to be digitalized and moved to the MRO IT system for seamless use. For example, comparison of current scrap rate, current removal rate, current mean time between unscheduled removals (MTBUR), current float etc. can be compared with the respective data recommended and corresponding Root Cause Analysis can be done if there is a variation.

RSPL or IP information provided by the OEM during induction or fleet expansion can be used at any time for comparing current inventory levels with recommended values and to analyze the reasons for the variation.

Inventory control systems

One key aspect of airline spare parts management is location sensitive availability of spares. If an aircraft on Line needs an item at Station-A and it is available at Station-B which is 30miles away, it will be an aircraft on ground (AOG) situation if the transit time for the aircraft is 20 Minutes. There needs to be a quantity distributed across the locations, for parts classified as LRU (line replaceable unit) and No-Go. The determination of distribution quantities to the line stations has to be determined after balancing the existing float quantity with the desired service levels.

Inventory control systems like Re-Order Point and Min-Max have to be set at each location and for each part, the replenishment lead time has to be taken into account and monitored regularly. When the items go below the re-order or minimum levels, the IT-MRO system should automatically trigger the replenishment without any manual intervention. The replenishment action should preferably be set as auto transfer from the base, which leads the centralized operations and feeds information to the line. This set up will ensure the base stores get an automatic alert for replenishment and the item is dispatched immediately to the line. Periodic review and adjustment of ‘Re-order/Min’ points is necessary due to the dynamic nature of consumption and turnaround times (TAT). However movements to the Line Station should be brought to the attention of the AOG desk or central planner before the transfer. Refer Fig 6.

%20Fig%206.jpg)

Fig 6: Demand Matrix to auto replenish the Line from base stores

Spares Demand Management

Fig 7: Spares demand management

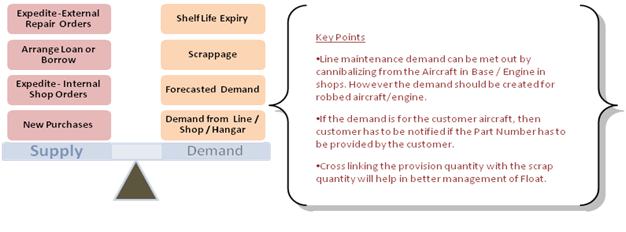

There’s always a balancing act required to meet current and forecast demand with on-hand and expected supplies. Forecast work scope and grounding schedules for aircraft engines and components has to be planned taking into account the availability of parts required to carry out the required work scope. If the required parts are not available, then possible ways to meet the demand within the given time should be worked out.

Demands arising out of non-routine defects during maintenance are inevitable and planners have to be highly responsive to meeting these unforeseen demands to avoid the work stopping or an AOG delay. A complete visibility of spares in the warehouse, in the repair shop, in transit between bases and from supplier shipments, with external repair agencies, in customs clearance, under receipt inspections etc. will help the planner expedite and meet demand. The possibility of exchange can be explored with the repair vendor to meet the demand on time.

If the demand is for a short period, for example, if an aircraft needs the item at an outstation which doesn’t have stock, the possibility of pool access through IATP (International Airlines Technical Pool) membership or taking the item on loan can be worked out.

Materials planners should forecast planned demands for varying time scales. The forecasting can be as low as six hours to 24 hours for line maintenance and can span anywhere between two months to 24 months for the base maintenance with varied time scales for engine and component maintenance forecasted demands. For forecast demand, simulated balancing of required quantity, projected receipts and on hand quantity will help the planner find out the actual shortage items and take necessary steps to balance.

Inventory analysis

It should be ensured that proper inventory control systems meet the desired service levels and, at the same time, do not lock-in cost with excess inventory. With thousands of part numbers to be managed, it is helpful to classify the items for selective and better control.

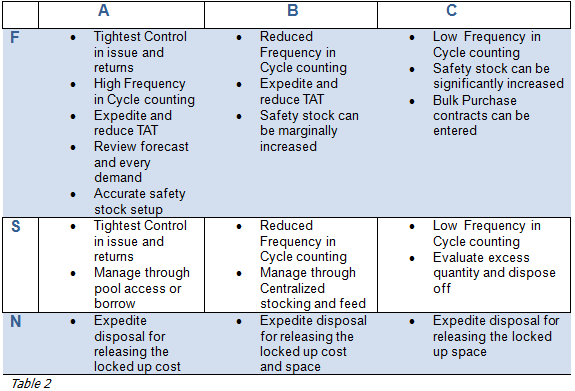

ABC Analysis: this works on the consumption value for the given period of the time that the parts are accounted for: for example, say, 70% of parts might be classified as cost group A, 20% as B and 10% as C. This analysis helps in focusing the type A parts more in a periodic cycle count, which increases the inventory accuracy and also helps in tightening the cost control. Carrying C class items add little to inventory value; due to this, items safety stock can be set higher to avoid stock-outs and bulk purchasing contacts can be established with the vendor for volume discounts.

FSN (fast, slow, non-moving) Analysis: this works on how fast the item is moving within the organization. For example, if fast moving items get transacted once in a month, slow moving items once in six months and non- moving items once a year, this analysis would help organizations to enter a bulk purchase arrangement for fast moving items which will lead to cost savings. Non-moving items can be periodically reviewed and disposed of, which will clear the inventory carrying cost and create space for other items. This analysis also helps in arranging the stocking layout to reduce handling.

Organizations do follow other types of analyses like VED (Vital, Essential, Desirable) or XYZ (Based on the items unit cost), with the objective of selective grouping of the item and managing for maximum benefits. Performing the multiclass analysis will significantly add value to the planners for determining probable next steps.

Float and scrap management

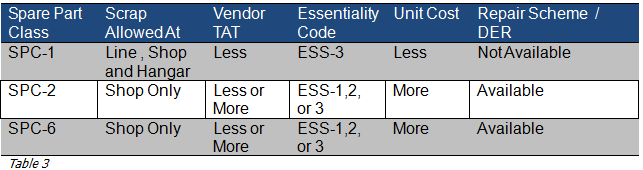

With Aircraft Spares Inventory running into millions of dollars, the decision to scrap an item should be properly managed. The decision to scrap the item has to be taken with due consideration, whether DER (designated engineering repair) procedures exist for the item or not, so that it can be refurbished economically and any sub components can be cannibalized for future use. If the item is deemed as scrap, necessary approvals have to be sought before it is defaced and moved to a scrap yard. Replenishment of scrapped items can be timed immediately after scrapping or when the demand for the item arises, based on multiple factors such as Cash Outflow Control, vendor TAT (turn-around time), essentiality and float requirement of the item. If a ‘no-go’ item is scrapped and vendor TAT is lengthy, provisioning has to be triggered immediately.

The decision to replenish a scrapped item through provisioning has to be preceded by analysis of the current float situation and comparison with recommended float levels. If the current float is greater than the recommended float, replenishment can be put on hold to ease cash flow. However for a ‘no-go’ item, if the current float is less than the calculated float and TAT is high, the planner has to arrange temporarily for interim requirement and initiate the replenishment immediately.

With multiple parts getting scrapped every day across bases; performing analyses, effecting part movements and initiating provisioning need to be automated without much manual intervention. This can only be possible with the proper classification of parts and provision to set scrap rules, (i.e.) whether it can be scrapped in Line or Shop. Once it is scrapped, the decisions on what should be the replenishment action and when it should be triggered, should be taken. Suggested mapping for better cost control is as shown in the table below:

Conclusion

Airline Material Planners across the world have responsibility for ensuring that, aircraft depart on time. Be it line or hangar, they are equally responsible for the management to achieve this within the constraints on spending on inventory. Material Planners can never be replaced by any software or systems, but holistic MRO IT systems with high flexibility in managing the varied dimensions and seamless integration between various functions, will enable them to tame the chaos.

Glossary:

| IATA – International Air Transport Association | ETOPS – Extended Twin Engine Operations |

| MCTF – Maintenance cost Task Force | RVSM – Reduced Vertical Separation Minimum |

| RSPL – Recommended Spare Parts List | HAZMAT – Hazardous Material |

| IP – Initial Provisioning | SRU – Shop Replacement Unit |

| AMM – Aircraft Maintenance Manual | LRU – Line Replacement Unit |

| CMM – Component Maintenance Manual | AOG – Aircraft On Ground |

| INC – Interchangeable | DER – Designated Engineering Repair |

| OEM – Original Equipment Manufacturer | IATP – International Airlines Technical Pool |

| MRO – Maintenance Repair & Overhaul | TAT – Turnaround Time |

| SB – Service Bulletin | MTBUR – Mean time between Unscheduled removal |

| MPD – Maintenance Planning Document |

Comments (0)

There are currently no comments about this article.

To post a comment, please login or subscribe.