Articles

| Name | Author |

|---|

Case Study: KLM Cityhopper makes a change for the better

Author: Ferry van Zalen, General Operations Engineer, KLM Cityhopper

SubscribeKLM Cityhopper makes a change for the better

Ferry van Zalen, General Operations Engineer, KLM Cityhopper and Martin Lidgard, CEO, Web Manuals share the airline’s experience of the Digitization of Flight Operations Manuals and improved Regulatory Compliance

KLM Cityhopper (KLC) has been using a digital solution for manual production, distribution and maintenance for about two years (at the time of writing) and has established a strong working relationship with the solution provider, Web Manuals. As this is a very topical subject for many airlines, we’d like to share that success story with readers. Today, all KLC Operations manuals and support processes have been implemented in the new system and all regulations, such as EASA (European Aviation Safety Agency) and IOSA (IATA Operational Safety Audit), are linked to the content of those manuals to assist and demonstrate regulatory compliance. The airline is now integrating other manuals into the new solution. But why undertake the program at all?

THE NEED FOR A NEW SOLUTION

As with any airline, KLC faced a number of challenges in this area, including the need for compliance. In past years, the airline used an Excel sheet which was a challenge to maintain, especially when one was dealing with different compliance officers. Moving to a dgital Manuals system has proved a great improvement. KLC previously used Framemaker to produce PDF files for the pilots and cabin crew; but Framemaker users needed special training in order to be able to produce those manuals. There were only three qualified editors in KLC at the time and they were responsible for all the manuals. Having identified the challenges, KLC then had to find a solution to address those challenges.

SELECTING A NEW SOLUTION

The first step was to undertake a survey of potential vendors who worked in this area and, following that, Web Manuals was selected as the solution best suited to KLC’s needs. The interface is a workmanlike environment, it is easy to use, doesn’t require specialist editors and the link with current regulations was very important for the airline, an area that had been identified as needing improvement. With more editors, the airline can spread manual production around different departments, plus it’s possible to link those manuals together and to make those links visible. There are other companies who provide an output for manuals, but they don’t have any links to legislation.

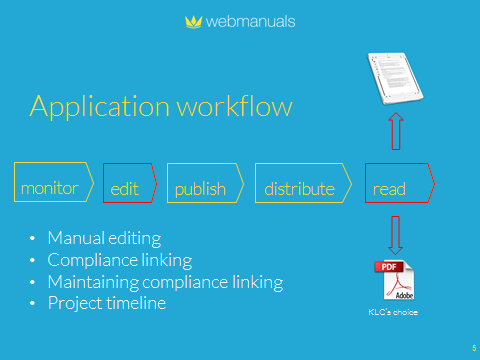

KLC has a meeting structure (document review meeting) where the airline takes care of all the changes, following which each editor takes care of their own manual. Web Manuals supports different workflows which can be viewed through five key steps (figure 1)…

Figure 1

- Monitor different sources of information such as regulations and standards, change requests from pilots and other readers, plus, of course, cross references between documents with all the documents and technical manuals being interlinked to ensure that changes are effective in all manuals where they have an application.

- Edit using a web-based tool for writing; what you see is what you get, there’s no complex XML coding or specialist training needed to be able to use this tool.

- Publish: once the editing is complete, it’s possible for multiple people to collaborate on this stage There’s a review and approval process leading to publishing and then on to…

- Distribute in multiple formats: either through Web Manuals’ distribution portal, with web documents able to contain more interactive content than you’d expect to find in a PDF document, or to electronic flight bags (EFBs) on iPad or Windows tablet devices with fast synchronization with reader apps. Also, where there is an existing distribution system in place, it’s possible to publish the documents as PDF documents.

- Read: the next stage will include switching to the reader app from Web Manuals. It’s also possible to use the new solution with Web Manuals partner AvioBook (KLC’s EFB solution) as well as other applications.

MANUAL EDITING

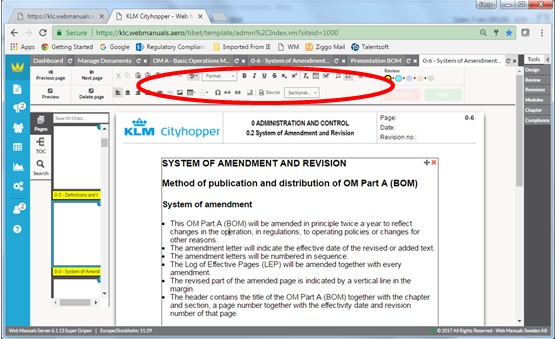

In Figure 2.1 you can see the interface with Web Manuals. Circled in red at the top you can see more or less the same formatting and style options (pre-defined) that you would expect to see in MS Word.

Figure 2.1

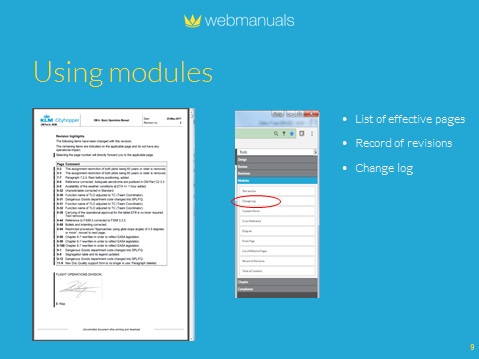

It’s also possible to import graphics and tables as you would in a normal Word environment. One of the big advantages for manuals is the modules (figure 2.2).

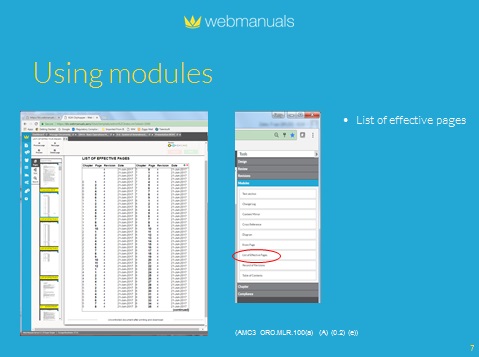

Figure 2.2

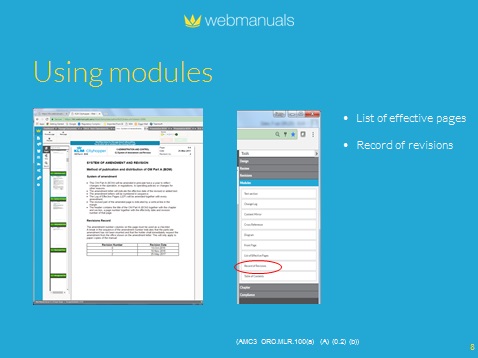

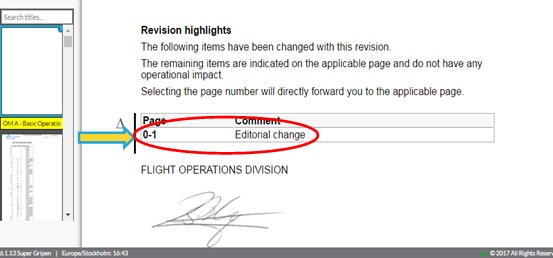

The module is simple for the user as it takes care of everything. In figure 2.2 there’s a list of effective pages, a requirement from IOSA, which takes the data from each page, such as page number, issue date and revision number. Another module is the record of revisions (figure 2.3). The revision is set up once with a prepared part and then the user puts in the revision number and the date and it is immediately fed into this record of revision. This means it is always possible to keep track of the number of revisions that have been done and when they were done. Enter it just once and it’s all done.

Figure 2.3

Figure 2.4

Change log is a module which gathers data from the changes made in a manual and allows users to write comments that are reported in the overview. It’s easy for users to see all of the changes in the manual. Plus, if the app is being used, it is easy to simply click on the ‘Change’ button and go through all the changes step-by-step.

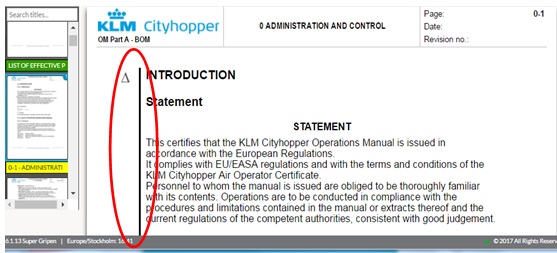

Figure 2.5 also illustrates a change by means of a revision bar and a triangle (the triangle is only available in the system and in the app, not on the PDF file where no interaction is possible) and if a user clicks on the triangle a ‘Content changed’ window opens (figure 2.6) where the user can see what has been changed – see header and change both circled in red – with the old, incorrect copy struck through and highlighted red while the new, correct copy is added and highlighted blue.

Figure 2.5

Figure 2.6

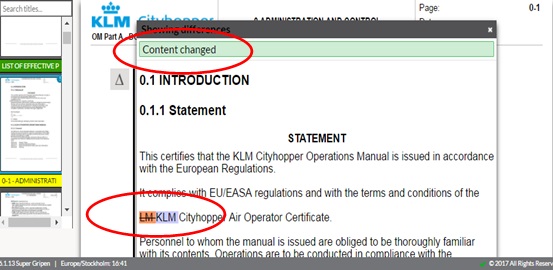

This is also available in the Reader App so that pilots can check what has been changed. At the bottom of the ‘Content changed’ window (figure 2.7) there is space for a comment which will be included in the change log (figure 2.8) as soon as the user clicks ‘Change’ (green button).

Figure 2.7

Figure 2.8

Other features include the capability to include important comments. So, while you are editing, it’s possible to directly keep comments so that there’s no need to create other documents later for comments. You simply make the changes and write the comments all in the solution.

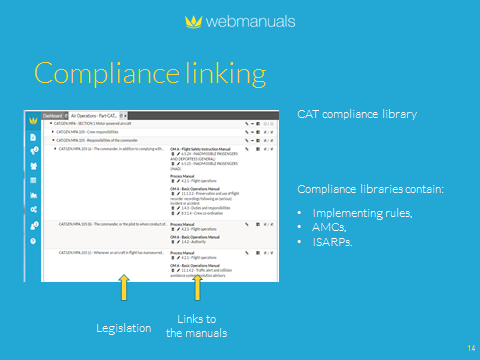

COMPLIANCE LINKING

For KLC, the most important feature in the Web Manuals solution is compliance linking (figure 3.1)…

Figure 3.1

… where you will see, on the left, the regulation (in this case, Part-CAT from EASA) with, on the right side, the links to the manuals where issues emanating from the regulation are addressed. With the overview, it’s very easy to see what is right and wrong with color coding – in this case, everything is black and so we know it is right. If something has changed, header or legislation, the links turn red which means that something has to be done. One nice feature is the tick box (left side of screen for documented; change needed: right side for implemented; incorporated in the manual). That makes it easy because, as soon as the regulation changes, all the relevant links will become red and the text boxes are removed. There’s an option in the system to filter on the tick boxes so that it’s very easy to spot all the changes in the libraries driven by that change in legislation.

Webmanuals has incorporated the EASA implementing rules and AMCs (Acceptable means of Compliance) as well as IOSA ISARPs (IOSA Standards And Recommended Practices).

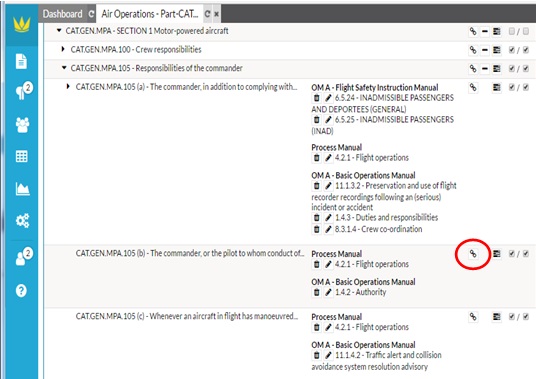

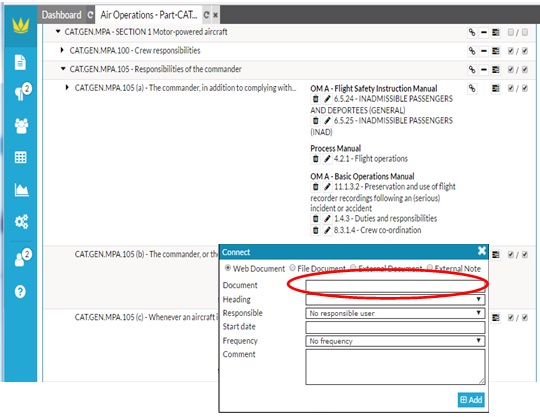

Changing or creating a link

If the user wants to make a change or add a link, they click on the link (figure 3.2, circled red) which will open a new menu (figure 3.3) enabling them to make appropriate changes in all relevant manuals.

Figure 3.2

Figure 3.3

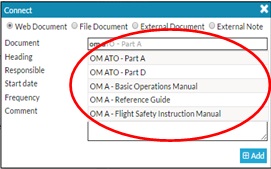

For example, if you click on the ‘Document’ box (figure 3.3, circled red) and type in the type of document you want to find, a list appears (figure 3.4)…

Figure 3.4

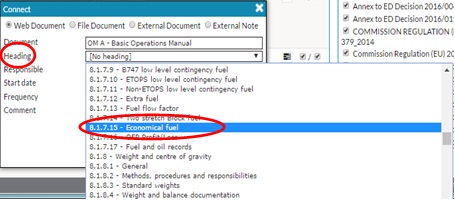

… automatically filtered alphabetically. From there, users can select a particular manual, say the ‘OM A – Basic Operations Manual’ and then use the drop-down menu in the ‘Heading’ box to select a heading available in the Basic Operations Manual (figure 3.5).

Figure 3.5

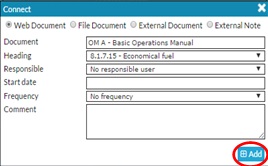

Again, click on the heading that you want to implement to open a further window (figure 3.6).

Figure 3.6

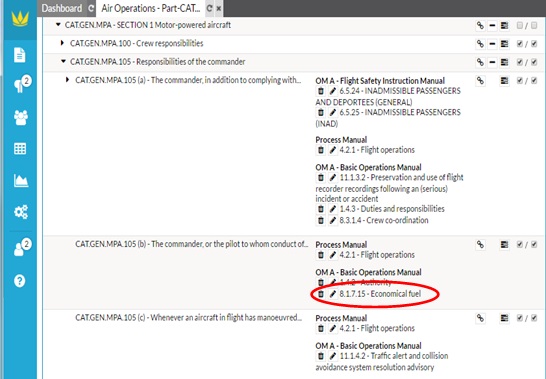

Then click on ‘Add’ and the link will be added to the original screen (figure 3.7, circled in red).

Figure 3.7

The same process can be applied if you wish to change something if, say, you’ve added the wrong header. Just click on the ‘pencil’ icon to get the same windows process and re-set all the fields for the correct heading.

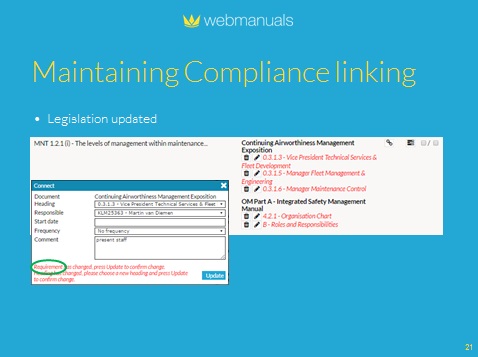

Maintaining compliance linking

If all links show up as red (figure 4.1), it is likely that the requirement has changed following an update of the legislation.

Figure 4.1

Reading the requirement (circled green) and checking the manual(s) is easy to do by clicking on the link which will take you to the manual, to see whether it’s still correct. If it is, you update by clicking on ‘Update’ and the link is corrected again.

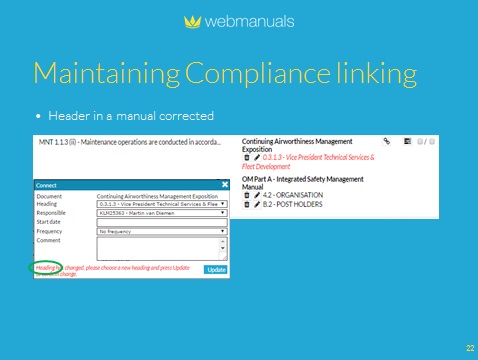

In figure 4.2, something has happened in the manual itself, the header or the number is changed, the headers have been moved around or additional headers added to change the numbering. This needs to be updated. The process is exactly as before, however if you’re in the manual, there is also a section called ‘Compliance’ (not illustrated here) where users can see exactly which link is available from that page to the relevant part(s) of the library. Again, if there’s a red link here, that can also be corrected from the manuals.

Figure 4.2

Another advantage of the solution is that only the editor of a particular manual can change links associated with that manual, whether in the manual or in the library.

These are the benefits KLM Cityhopper identified from implementing the new digital Flight Operations Manuals and Regulatory Compliance solution and processes. Bearing all this in mind and having completed the selection process, KLC determined to proceed with the manuals solution.

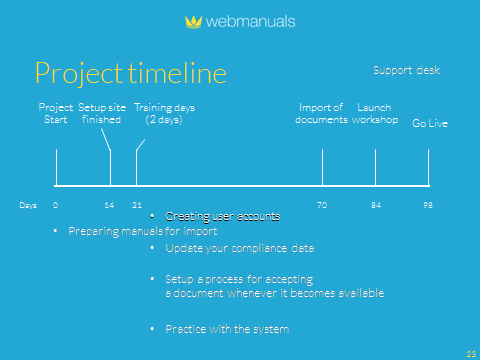

PROJECT TIMELINE

Figure 5

Having decided to go ahead with Web Manuals, from commencing the project it took 14 days to set up the new environment and a further seven days to get the manuals in there (KLC let the vendor complete that task as their experience of previous projects meant that they could get it done faster and with less problems than the users). During that time, KLC and Web Manuals also completed two days of training in which the vendor guided users through all the processes and steps they would need to know. Users were also trained in how to set-up a template (KLC logo, font size…). There followed the long process of transferring the documents into the new system. During that time, user accounts were created and compliance data was updated with the compliance links available in the solution. A process was established for accepting the manuals and there was time for users to practice with the system using test documents and with resort to the Support Desk if need be. The Support Desk is always available for users of the Web Manuals solution. Once the project was underway, KLC was ready to hold the launch workshop, including updates on any changes made thus far and to answer any questions that users still wanted to ask. Finally, KLC’s new solution had the ‘Go Live’.

EXPECTATIONS AND OUTCOMES

At the outset, KLC harbored some concerns about the layout of documents in a new solution but that was probably more to do with familiarity with the way things had been done before. In the event, the new layouts didn’t cause any problems. There were also some high expectations for compliance which was an area of concern for KLC and where, as the comments above illustrate, things have greatly improved with the implementation; plus the solution has proved easy to maintain. With the new system, KLC increased the number of editors in the organization to seven as some departments became involved in manual and document management that had not done so previously. This also ensures back-up in the event of an editor being unavailable for sickness or vacations.

Implementation of the new system was completed within 100 days which suited KLC’s timetable but time had to be allowed to import the manuals, which takes quite a long time if it’s to be done correctly and lay a sound foundation for the future. Given that this has to take place while normal business continues, KLC opted to let Web Manuals complete this task.

Importantly, there are now structured links between the regulations that apply to KLC and several different manuals that the airline uses, as well as links between manuals which ensures that whatever area a new document or a revision might affect, the relevant manuals will flag up the need for change.

BENEFITS

The first benefit is a time saver where amendments to manuals at KLM Cityhopper now only take 2-3 days as opposed to the three weeks that they previously required. Making the change log used to be a hassle with the list of affected pages always incorrect whereas now, it is so easy to do and always accurate. That gives KLC more time to make changes to the manuals that will add value to the business.

There are now a number of changes that can drive the content of documents and manuals and that can be easily incorporated. These include:

- Regulatory changes;

- Organizational changes;

- Operational changes.

Most important and resulting from the linking (see above), the new system reduced the risk of missing any regulatory changes so ensures that KLC is compliant. The regulations and standards that are maintained in the system include EASA, FAA, IOSA and IS-BAO (International Standard for Business Aircraft Operations) Aviation standards and they’re maintained on a monthly cycle with any changes notified to the responsible people within airlines using Web Manuals. The user, in this case KLC, can postpone action on a change for up to a month where compliance does not require immediate action.

NEXT STEPS

The key next step is to look further into the Web Manuals Reader and see how KLC can incorporate that into their systems as an app on its own, within another system. Another consideration is the workflow where KLC already takes care of regulation, manual changes and manuals production, and wants to automatically report back to the instigation of any process.

In summary, KLM Cityhopper is very happy with the change to a digital manual and documentation management system.

Contributor’s Details

Ferry van Zalen

Ferry has worked at KLM since 1986, initially as flight crew instructor. As from 2003 he has kept the Operations Manuals up to date and in compliance. For the last 18 months he was mainly occupied with the implementation of the Web Manuals system.

Ferry has worked at KLM since 1986, initially as flight crew instructor. As from 2003 he has kept the Operations Manuals up to date and in compliance. For the last 18 months he was mainly occupied with the implementation of the Web Manuals system.Martin Lidgard

Martin Lidgard, is CEO and Founder of Web Manuals International AB, a Cloud based application for easy and controlled authoring, publishing and distributing operational and technical manuals within the aviation industry. Martin has a broad background in the fields of Engineering Physics, Finance and Business Administration and has founded and headed two successful companies in the IT sector in Sweden.

Martin Lidgard, is CEO and Founder of Web Manuals International AB, a Cloud based application for easy and controlled authoring, publishing and distributing operational and technical manuals within the aviation industry. Martin has a broad background in the fields of Engineering Physics, Finance and Business Administration and has founded and headed two successful companies in the IT sector in Sweden.KLC

KLC is the regional airline subsidiary of KLM headquartered in Haarlemmermeer and based at nearby Amsterdam Airport Schiphol. It is an affiliate of SkyTeam and also a subsidiary of Air France–KLM and operates scheduled European feeder services on behalf of KLM. The fleet includes Embraer 170 and 190 types.

KLC is the regional airline subsidiary of KLM headquartered in Haarlemmermeer and based at nearby Amsterdam Airport Schiphol. It is an affiliate of SkyTeam and also a subsidiary of Air France–KLM and operates scheduled European feeder services on behalf of KLM. The fleet includes Embraer 170 and 190 types.Web Manuals International AB

With headquarters in Malmö, Sweden and an office in San Diego, California. Web Manuals is a tool for digitizing manuals to simplify authoring and distribution of company manuals for the aviation industry. Web Manuals is used by more than 140 flag carriers, regional operators, wet-lease operators, business jet operators, helicopter operators and aviation service providers in Europe, the US, the Middle East Asia and Africa.

With headquarters in Malmö, Sweden and an office in San Diego, California. Web Manuals is a tool for digitizing manuals to simplify authoring and distribution of company manuals for the aviation industry. Web Manuals is used by more than 140 flag carriers, regional operators, wet-lease operators, business jet operators, helicopter operators and aviation service providers in Europe, the US, the Middle East Asia and Africa.Comments (0)

There are currently no comments about this article.

To post a comment, please login or subscribe.