Articles

| Name | Author | |

|---|---|---|

| Charting an Optimal Course | JD Sillion, Chief Solutions Officer, Flatirons Solutions | View article |

| Moving Day, Getting Ready and Afterwards | David A. Marcontell, President & COO, and John F. Smiley III, Aviation Analyst, TeamSAI Inc. | View article |

| Case Study: New Generation Reporting Tools | Caroline Deba, Reliability Manager, Air Tahiti Nui | View article |

| Case Study: Enhanced Business Operations | Jorma Ryske, Director Finnair IT Aircraft Maintenance | View article |

Case Study: New Generation Reporting Tools

Author: Caroline Deba, Reliability Manager, Air Tahiti Nui

SubscribeNew Generation Reporting Tools

The daily use of AirStat enables Air Tahiti Nui to edit multiple indicators in a minimum amount of time, explains Caroline Deba, Reliability Manager at Air Tahiti Nui.

Data reporting is the part of a system that reports key elements relating to an airline’s performance in order to improve its operations and share these elements within the airline and/or with the civil aviation authorities and aircraft manufacturers. New generation reporting systems now go beyond simply reporting to provide a foundation for implementing a more efficient and interactive management model.

Beyond reporting

What major benefits can be expected from a new generation data reporting tool?

In the aviation industry, maintenance is considered a key factor in helping airlines succeed. It aims to provide the maximum performance at a low cost, within the parameters of safety, operational and environmental requirements. As a result, to maximize the airline’s profitability it is desirable to operate some components near to their failure point. This goal can be achieved through extremely strict and constant monitoring of the airline’s data and maintenance activity.

A new generation reporting tool should improve monitoring and analysis practices. Every airline collects data, however not all airlines have enough data, or are able to allocate the time needed to look at the collected data. The reporting system should be a time saver and not a time waster, allowing automation of data collection and their monitoring. Convenience is what every operator seeks as they do not want to make things hard for themselves: that might only let them down in the end.

A new generation reporting tool should improve monitoring and analysis practices. Every airline collects data, however not all airlines have enough data, or are able to allocate the time needed to look at the collected data. The reporting system should be a time saver and not a time waster, allowing automation of data collection and their monitoring. Convenience is what every operator seeks as they do not want to make things hard for themselves: that might only let them down in the end.

With the use of an appropriate data reporting tool, an airline can succeed in planning and knowing what’s going on. Row after row and column after column of numbers are pretty much meaningless to those who can’t make sense of the data contained in them. By translating data into a report, this information become more accessible, allowing the airline’s staff members to better understand the information and communicate with relevant colleagues and organizations. During the reporting process, data become easier to share and understand. Additionally, these reporting tools must include features with the ability to produce graphics that illustrate the meaning of data, making the reports even more accessible and the results more readily understandable and, importantly, not boring. The once complex task of comparing airline’s data and manufacturer’s data suddenly becomes effortless.

And lastly, it is important to enhance the accuracy of data. It can be hard to determine if data are actually accurate. But with the use of advanced data reporting tools, it becomes easier to identify mistakes. Inaccurate data and so-called ‘outliers’ are able to be changed by the user through tracking down data collection activities and changing them.

A next-generation reporting tool

ADSoftware, the French aviation IT specialist, developed AirStat in 2007 as a ‘reliability and statistics’ reporting facility for all the data stored into AirPack the company’s maintenance software solution. AirPack is a new generation software solution which improves safety and operational efficiency, meeting all requirements in terms of functionality, traceability, performance, aviation legislation and regulations. It is user-friendly, Web accessible, fully compatible with Microsoft Office products, and works on a standard PC (100% Windows© Technology). The software package includes six modules, linked together to achieve maximum efficiency: Airtime (fleet management- CAMO), AirStock (inventory control – logistic), AirDoc (documentation management), AirUser (security management), AirStat (reliability and statistic reports) and AirWork (time-tracking).

ADSoftware, the French aviation IT specialist, developed AirStat in 2007 as a ‘reliability and statistics’ reporting facility for all the data stored into AirPack the company’s maintenance software solution. AirPack is a new generation software solution which improves safety and operational efficiency, meeting all requirements in terms of functionality, traceability, performance, aviation legislation and regulations. It is user-friendly, Web accessible, fully compatible with Microsoft Office products, and works on a standard PC (100% Windows© Technology). The software package includes six modules, linked together to achieve maximum efficiency: Airtime (fleet management- CAMO), AirStock (inventory control – logistic), AirDoc (documentation management), AirUser (security management), AirStat (reliability and statistic reports) and AirWork (time-tracking).

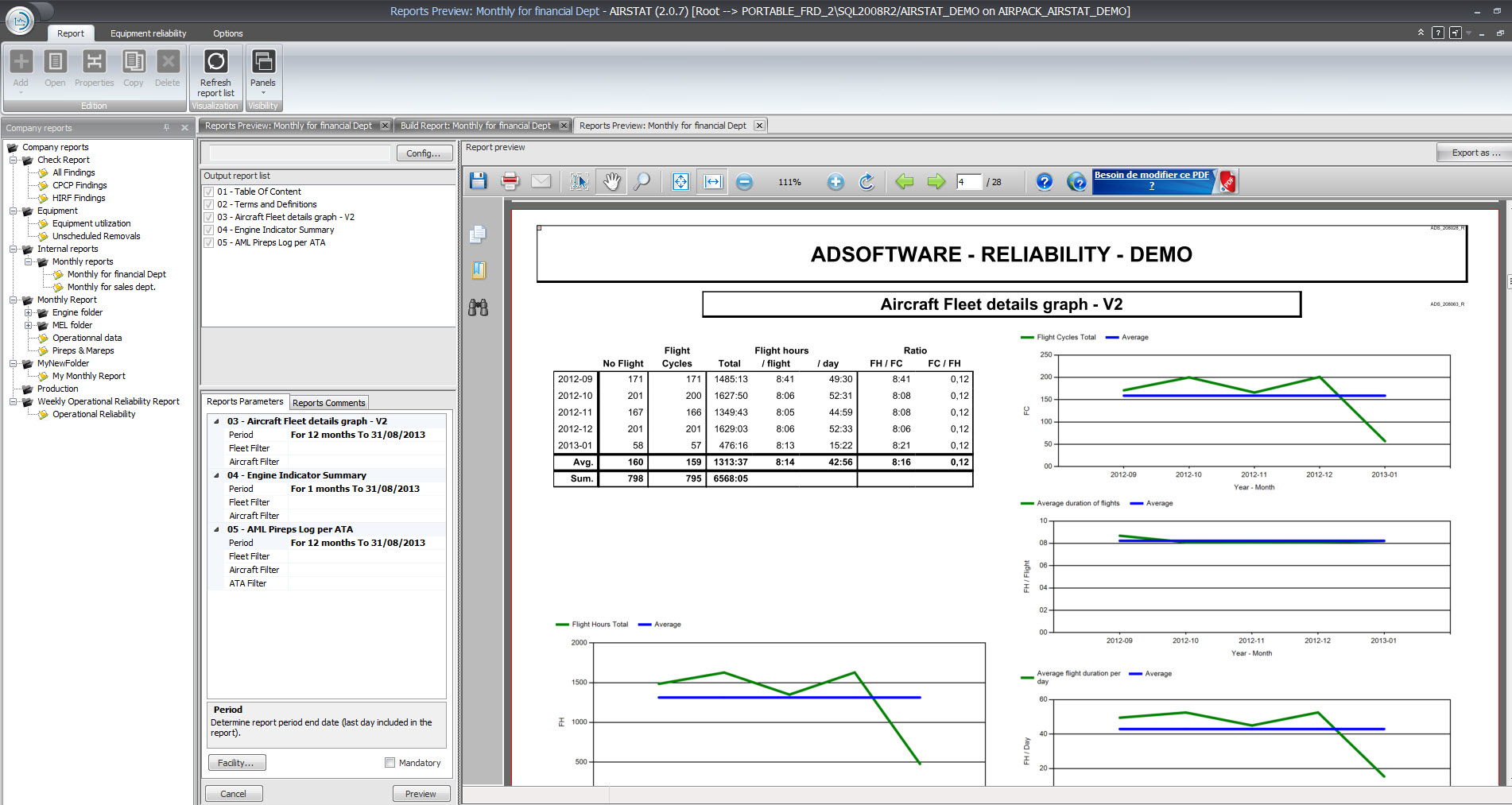

AirStat is the company’s new generation reporting tool which uses descriptive and predictive models to gain valuable knowledge from data analysis and uses these insights to recommend action or to guide decision-making processes. Its principle is simple it quantifies performances in complex statistical reports and allows users to choose a type of data visualization from a specialized library to communicate insights in a very straightforward way.

Users select a template from the library and can customize reports based on the recipients (customers, internal reports, authorities, manufacturers, etc.). AirStat generates dynamic reports (reusable) using scripts and preregistered filters. The distribution of these reports can be completely automated (i.e. PDF sent by email), as well as prepared and stored online. Reports might include weekly statistics on flight hours automatically sent to the shareholders of the airline. Furthermore a monthly reliability report for the local authorities or a weekly statistics report on the availability of aircraft can be generated.

Taking on maintenance management

Air Tahiti Nui, the main carrier of French Polynesia, operates one of the newest fleets of Airbus A340-300 aircraft in the world with five aircraft flying up to 15 times a week from Los Angeles to Tahiti, up to seven times a week from Paris-CDG to Tahiti, as well as twice a week out of Tokyo-Narita and Auckland-NZ. Since its foundation in 1996, Air Tahiti Nui has had to address the constraints of remoteness combined with regulatory requirements. This has meant managing inventory levels as closely as possible by reducing turnaround time and operating costs, and optimizing performance.

In 2006, the technical department of Air Tahiti Nui decided to take over the management of our previously outsourced maintenance program and implement a reliability program. The tasks of the reliability program are to monitor the health of aircraft by analyzing recurring failures reported by our crew, unscheduled removals of equipment, defects discovered during maintenance visits (corrosion etc.) and any operational impacts associated. In case of deviation of one of these parameters, measures are in place to return to an acceptable level of performance (adjustment of the maintenance program, standard equipment, staff training, and adjustment of the level of stock).

We have been using AirStock and AirTime since 2002 and decided in 2009 to acquire AirStat as a support tool in the reliability program; participating actively in its development. Daily use of AirStat enables Air Tahiti Nui to edit multiple indicators in a minimum amount of time, to monitor threshold exceedances on the pilot reports rated by ATA, to view findings rates by item and, recently, to track the reliability of the equipment with MTBUR (mean time between unscheduled removal) calculations, operating times, alert equipment removals thresholds, and inventory optimization. These indicators are used by Air Tahiti Nui for both analytical reasons and for communication with AIRBUS, OEMs, management and various departments within the airline.

I have taken some cases from the files of our software supplier, AD Software, to further illustrate the application of new generation reporting tools in a variety of airlines and operators.

As an approved EASA CAMO Part M/G organization and an experienced consultancy company, Regio Lease provides a range of tailored solutions to airlines, leasing companies and institutions covering aircraft continuous airworthiness management, airline consultancy / set up and aircraft asset management services and airworthiness review certification for EU import/export or renewal. Regarding its CAMO activities, Regio Lease is in charge of coordinating the compliance of its clients’ aircraft with maintenance programs, airworthiness directives, service bulletins, repairs and modifications. Regio Lease has used the AirPack fleet management system to this end, from the time they went into business and AirStat since it was launched by ADSoftware.

“For us AirPack feeds our methodology”, Says Laurent Le Minh Loc CEO of Regio Lease, “pushing for a direct communication between mechanics and engineers to ensure data integrity; and establishing procedures for filling out the task cards and other documents before the reliability department, obtains them. To assure data quality, it is necessary to have the correct information (such as aircraft events, flight hours and landings, LRU removals, and scheduled maintenance) related to the event, in order to perform statistical analyses. We focus on monitoring the performance of the fleet and associated equipment to identify possible correctives actions which could lead to immediate measures or could also impact on maintenance program efficiency.”

Regio Lease also handled the Safran A320-212 used for testing the Electric Green Taxiing System (EGTS) supported by AirPack and AirStat. To comply with the authority’s requirements, all the parts of the EGTS had to be followed up inside a Kardex model as if the aircraft was being operated within normal conditions. Reports incorporating all the new elements had to be produced to allow the aircraft to operate on the runway with the new system on.

Weststar Aviation Services Sdn Bhd, a subsidiary of the Weststar Group, is a company formed in April 2003 with an approved Air Operating Certificate from the Malaysian Department of Civil Aviation. The company operates 16 helicopters, including AW139, AW189 and EC225 to facilitate future expansion in on-shore and off-shore operations.

Weststar selected AirPack in 2011 to manage its maintenance, planning and integrated logistics. Michel Eymard, Chief Type Engineer AW139 at Weststar, uses AirStat to extract and filter all data in order to produce statistics and reliability studies and also to provide the reports requested by Weststar customers. Michel Eymard says: “Some key reports generated for management are purely informative and summarize our operations over a given period. They are necessary for the billing of flight hours and the monitoring of our fleet. Others allow us to identify abnormal usage, high turnover of specific parts (reliability study), recurrent failures, etc. These anomalies are very easily identified by the system [which] is a real time saver for Weststar with a positive impact on productivity.”

Héli-Union, a key international offshore helicopter company, just moved to an integrated airworthiness management software solution developed by ADSoftware. Héli-Union’s fleet is composed of eight types of helicopters (Cabri G2, 300CBi, EC145, SA365N, AS365N3, AS332L1, S76C++ and EC225LP) and will soon include EC175 helicopters, which will be the first European helicopter certified with a maintenance program based on MSG-3 process.

For its Continuing Airworthiness Management Organization (CAMO), Héli-Union needed efficient reporting software to help the engineering team draft reliability reports for its fleet and selected AirStat to analyze data stored in AirStock and AirTime. Jonathan Cosson, Technical Director at Héli-Union comments: “Héli-Union engineering needs a tool to help them with the analysis of the PIREPS (pilot reports), MAREPS (maintenance reports) and corrective items found during a periodic check. It is very important for Héli-Union to establish dashboards to follow up the performance of main equipment – MTBF (mean time between failures), MTBUR, and NFF (no fault found) – as well as the accomplishment of trend monitoring”.

Next-generation analytics are leading to broader perspectives in terms of aircraft maintenance, emphasizing the use of predictive maintenance techniques in addition to traditional preventive measures.

Preventative maintenance is based on routine measures to avert failure. It is a safe but costly way to maintain a fleet. Predictive maintenance is based on the monitoring of information/data and usage of trends and behavior patterns to carry out maintenance. It is an enhanced way to maintain a fleet and rationalize costs which requires a strict reliability program and therefore an advanced data reporting system.

The term ‘reliable’, as used by the aviation industry, applies to the dependability or stability of an aircraft system or a part thereof under evaluation. A system or component is considered reliable if it follows an expected law of behavior and is regarded unreliable if it departs from this expectation. These expectations differ greatly, depending upon how the equipment is designed and operated. An airline reliability program is a set of procedures aimed at collecting data related to the failure of the aircraft, its systems, sub-systems, components and parts. Further analysis of the data thus collected and making meaningful inferences using engineering judgment also forms part of the program. The actions based on those inferences, to improve the maintenance program, are what make a reliability program beneficial. These are the corrective actions enabled by a next generation reporting tool.

The purpose of the reliability analysis is to measure the effectiveness of the tasks within the maintenance program by alerting operators to the systems, components and structures whose performance digress from their expected levels. Reliability programs now form an integral part of an operator’s maintenance program, and are designed to supplement the operator’s overall program for maintaining aircraft in a continuous state of airworthiness.

Collecting data with the aim of having a reliability centered maintenance program is the way forward for operators and something that manufacturers are really trying to develop. It would be ideal for the manufacturer to have a system in place that allows for the collection of data obtained during the operator’s task accomplishment and then to enter them in a standardized format into its data collection system. The idea would be to exchange operators’ data against valuable technical data from the manufacturer. As yet, this remains very difficult to achieve due to external factors such as different networks, platforms, hardware, software compatibility, etc. Software developers such as ourselves are busy working on the automation of raw data export files to manufacturers and by extension the importing of technical data from manufacturers.

Today, the essential feature of any new generation IT tool is its exchange capacity. From social networks to mobile devices, the sharing of information is the key and software developers such as ADSoftware are working on this to establish new standards of connectivity in support of new generation reporting tools.

Comments (0)

There are currently no comments about this article.

To post a comment, please login or subscribe.