Articles

| Name | Author | |

|---|---|---|

| Be ready for GDPR | Sander de Bree, Founder and CEO of EXSYN Aviation Solutions | View article |

| A new way of looking at and managing pre-maintenance data Part 2 | Steve Sayers, Director of Technical Publications, FLYdocs | View article |

| Paper to Data — Data to Dollars Part 2 | Rob Saunders, Consultant, Aircraft IT | View article |

| New technologies and Blockchain | Mathieu Gimenez, Innovator at the MRO Lab Singapore, Air France Industries KLM Engineering & Maintenance (AFI KLM E&M) | View article |

| Digital twins, AI, mobile apps and drones | Mark Martin, Director, Operator Edition Product Line, Aviation & Defense Business Unit, IFS | View article |

Paper to Data — Data to Dollars Part 2

Author: Rob Saunders, Consultant, Aircraft IT

SubscribeTitle Paper to Data – Data to Dollars Part 2

Rob Saunders, Consultant discusses with Aircraft IT how Mobile M&E Solutions can improve a range of factors in maintenance efficiency and aircraft utilization and add realizable value to the business

We continue our interview with Rob Saunders which was started in the previous issue.

SAVING THE DOLLARS

All of the foregoing was interesting but the big question, of course, is how much money can be saved? Here, Rob had to be a little more guarded. “That is very difficult to know exactly because there’s no way of knowing what a delay will cost until there is one. Of course, it’s easy after the event but typically delays and cancellations avoided are not well recorded. Moreover, the cost of a delay itself seems to be quite arguable with many different numbers from different sources. Having said this, the consequential costs of missed connections, displaced crew, consequential delays are far more significant to the airline even if not so much to the Engineering budget. As airlines expand their IT capabilities in bringing their systems’ information together in an accessible way, the true costs often referred to as intangible are becoming tangible and better recognized.”

This led us into the subject of Big Data and Digital. So what will this do for airlines? Rob’s response was reflective, “This is something in which I’ve always been very interested and have found a little amusing. There are a lot of people promoting Big Data and it’s going to save us.”

Big Data – only as good as the inputs

In a return to his characteristically positive outlook Rob continued, “I think that if you give it a clue, big data will produce an answer but we risk overestimating its current capabilities. This is something that always looks like it should deliver, and I’m confident it will, but I’m not yet aware of anything game changing that’s fallen out aside from data validation of what we kind of suspected already – which in itself is very helpful – but I don’t think it’s the answer to everything yet. One reason is that, unless there is very accurate data going into the data pool, the algorithms advertised will give us very informed answers on ill-informed data and that will be a problem. That, I believe, is where the mobility apps start coming in and that’s the true value here. Yes, absolutely we can look at productivity improvements and ease of use, but I think getting accurate information at source is going to be of key importance to big data being valuable. It also seems that suppliers are suggesting new sources of data for the data pool when we are probably not getting the best out of what we already have.”

BIG DATA AND BIG DOLLARS

We had been talking about big data but big dollars are the answer that the CEO wants. In this context, Rob suggested that there are a few things to consider about cost management.

“I’ve spoken to a number of airlines in various forums and was also fortunate enough to work with an airline group for a few years. Generally speaking most airlines have a focus on operational performance (OTP), reliability metrics and stock service levels etc. This is the ‘interesting stuff’. But there are some big costs that can be influenced but that might not get the attention they deserve. As an example, most airlines have a warranty person or even persons. These are super people who do a wonderful job probably in a way that has been in place for many years. They usually have spreadsheets, Access databases etc. that they have enhanced themselves for incremental improvements. Following a project to create warranty enhancements using a wider set of information that was already available, warranty claims increased by 200 per cent. This was very welcome but quite unexpected. When you start to look at things like repairable items that aren’t serialized on their first removal and automating that sort of thing, which can be done with data and a good M&E system, you can get serious money back. I’m not sure if this can be classified as big data but it is exactly the right result.

“In a similar vein with component overhaul, having more information enables users to look at alternate sources and that can be alerted automatically. With engine hours, new aircraft types have DAC (Direct Accumulation Count) cycles which enable partial cycles to be counted based on operational data. If you can automate that coming out of your system and track it, then this will support lower cost per flight hour contracts.”

Leasing

Another opportunity to turn data into money would be with leasing where, “If you can get ground time down from three months to even two months,” Rob suggested, “that amounts to another month of operation for that aircraft. Also if you’re not late on return, you will avoid penalties.”

UTILIZATION

So, we could easily understand Rob’s rationale for turning data into money but what about the other major consideration: utilization? He suggested that airlines check escalations. “If you can pull accurate data from your mobile system where you are automatically tagging the non-routine back to the originating maintenance schedule item, you’ve got a very rich source of data that can be mined accurately to actually suggest, ‘check escalations’. If any of it is missing, then there’s a question and you’re going to have a problem with the regulator. This is an area where, when you can have very accurate tagging that has been codified at source, providing a much better source of information.”

Heavy check downtimes

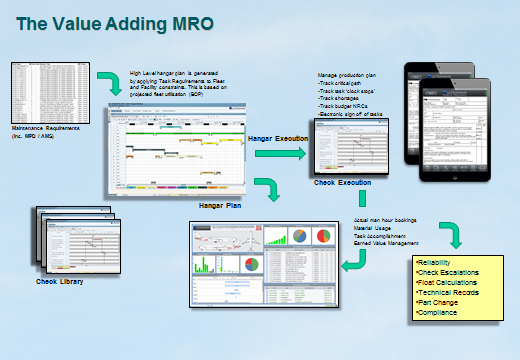

Figure 9 is about the MRO adding value. Some people in the MRO community are saying that in Asia there is over capacity of MRO services which, if correct, could mean less demand for maintenance than the MROs expect. Of course, it could go the other way, with a boom in aircraft operations leading to more maintenance requirement. But either way, MROs will need to be more efficient to offer an extra advantage to their customers and, if not, they’ll need to be more efficient to exploit the demand. The bottom line is faster Base turn times are good for everyone regardless of the market demand.

How does Rob see ‘data to money’ being of value in either scenario?

“What I’d like to see from an MRO is firstly loading the maintenance schedule, the MPD (Maintenance Planning Document) and generating a long term hangar plan sympathetic to the airlines’ needs. This is entirely possible with some of the applications that can generate a ten year plan in about two hours, if you’ve got the data, and then take this data through to individual checks.” That was his opening comment, continuing, “It’s possible to generate a Check Library to pre-load sequenced tasks within the checks. The Mobile Mechanic applications being produced by some suppliers enable production managers to see and actually sign-off these tasks in real time. It’s all available. This means that hold ups and clock stops can be proactively managed and down times reduced.

“What the airline really wants is to get the aircraft out quicker. They’re not so worried about how efficient the MRO is but, if the aircraft can be out sooner, it can add another airframe or part of an airframe to the fleet at no extra cost. This is really where the money is. All the things in base maintenance are great but what the airlines want is faster and reliable turn-around times. And I am convinced that aircraft today are on the ground too long. Even if an aircraft comes out on time, if you’ve got supply chain problems and all the inefficiencies, it was planned on the ground for too long in the first place. There are enormous opportunities now that these applications are maturing: the effort of getting them up and running is worthwhile because there’s a lot of dollars to be saved. For instance, if aircraft are generating say US$50,000 to 70,000 a day, applying that average return to even half an airframe across a year will amount to huge benefits for the airline.”

“So, Mobility can provide the data to support reduced grounds times and check escalations. Although many other factors are involved, it’s reasonable to aim for a whole airframe to be liberated from a 50 aircraft fleet by reduced maintenance ground time requirements.”

Algorithmic forecasting

Warming further to the topic, Rob suggested another opportunity that’s becoming available with data. “Let’s say we look at our gear removal cycle and we run this application to forecast when the gear are going to be removed;” he considered, “if you can accurately tell the supplier that the gear is coming off on this day or even within this month in three years’ time, then you can share that value with the supplier. If you then start applying that to all repair orders, suppliers can manage repairs to your maintenance needs and reduce their overheads. It’s great for the maintenance side but it’s also good for supply chain, will reduce the budget and make it more predictable. This is the power of accurate data and that is where the money is.”

Other benefits from data

There are also some less direct benefits that can be generated with data. As Rob explained, “Compliance is a given until you’re ‘out of it’. If you go out of compliance, you could be grounded at huge cost so, again, it’s worth investing to avoid that risk. And this, again, is how the accuracy of mobile applications, the intelligent applications, the data hunter gatherers back to the M&E system or through to alerting systems such as Boeing’s AHM or Airbus’ Airman are so important.”

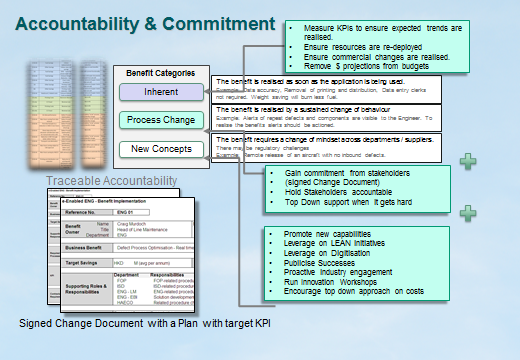

GETTING IT DONE – ACCOUNTABILITY AND COMMITTMENT

So we understand the value of having data capable of being used but how do you do all the above things, we wondered? It’s all very well standing in front of the people in the finance department and promising that if they let you spend this money on this system, you’ll be able to give them the money back. However, they might be skeptical. In response, Rob recalled, “One thing that I have developed and used is to look at inherent benefits, process change methods and new concepts (figure 10).

“An inherent benefit would be; put an e-log in, you will get the MEL right you won’t have a mistaken over-run so it’s inherently better. The data integrity is inherently better and there won’t be large volumes of paper. The process change is really about using it. If you’re going to go out and buy a new system but don’t put the effort in, don’t change the way things are done, you probably won’t get the benefit. So, when I hear that 60 per cent of IT projects are unsuccessful and don’t deliver, it’s not necessarily the application, it’s the organization, the adoption.

“The idea is to build an environment that invites innovation. Then get a traceability document in which the budget holder writes a plan to say how he’s going to do it, at which point he has to consider how much money he really thinks he can save and identify the resources he really needs because it’s a lot more difficult to write it down and commit than it is to talk about it. Then, take that document and get the budget holder to sign it. Ironically, having just talked about the merits of electronic signature, an inked signature on an implementation and benefits document is probably a good way of getting real commitment, an internal contract if you like.

If there was any doubt then this will be the time to find out. Finally, you then take the money from the budget in line with the benefits realization plan. That has proved to be quite a reliable way of making sure that the people buy-in. It’s much more effective than getting a show of hands in a management meeting.”

SUMMARY

With our meeting drawing to a close, we thanked Rob Saunders not only for his clear responses to a topical issue but also for his detailed explanations and examples that had make what could be a challenging subject into something very understandable.

Contributor’s Details

Rob Saunders

Rob’s career started with British Airways in 1977 then, in 1990, joined Cathay Pacific as a Maintenance Controller where he saw the introduction of the 747-400 and Airbus fleet. In 1994 he managed the Base Maintenance Support team then as Manager of the Maintenance Control Centre in 1997. In 2002 he held the position of Manager Ultramain Program, replacing Cathay’s legacy Engineering IT systems. In 2006 Rob was appointed Manager of Aircraft Engineering with technical responsibility for Cathay and Dragonair’s Boeing and Airbus fleets. As Head of Business Improvement & Lean, he led a team implementing many productivity and compliance related projects. Rob left Cathay Pacific in June 2017 to be a consultant but continues to support the One World engineering group, IATA Paperless Operations and standards and is currently chair of the Boeing /USI eLog user group.

Rob’s career started with British Airways in 1977 then, in 1990, joined Cathay Pacific as a Maintenance Controller where he saw the introduction of the 747-400 and Airbus fleet. In 1994 he managed the Base Maintenance Support team then as Manager of the Maintenance Control Centre in 1997. In 2002 he held the position of Manager Ultramain Program, replacing Cathay’s legacy Engineering IT systems. In 2006 Rob was appointed Manager of Aircraft Engineering with technical responsibility for Cathay and Dragonair’s Boeing and Airbus fleets. As Head of Business Improvement & Lean, he led a team implementing many productivity and compliance related projects. Rob left Cathay Pacific in June 2017 to be a consultant but continues to support the One World engineering group, IATA Paperless Operations and standards and is currently chair of the Boeing /USI eLog user group.

Comments (0)

There are currently no comments about this article.

To post a comment, please login or subscribe.