Articles

| Name | Author | |

|---|---|---|

| Using big data to schedule unplanned maintenance… streamlining the A&D support chain | Brendan Viggers, Product & Sales Support, IFS A&D Centre of Excellence | View article |

| Column: How I see IT – 3D, or not 3D? That is the question | Paul Saunders, Solution Manager, Flatirons Solutions | View article |

| The Internet of Flying Things: Part 2 | Michael Wm. Denis, a renowned author, speaker and independent consultant | View article |

| ‘Less is more’: MRO Software Implementation at FL Technics | Ramunas Paskevicius, Head of IT Unit, FL Technics | View article |

| Case Study: Rotary Wing MRO IT Case Study | Jan Ketelsen, Manager Maintenance Planning, ADAC Luftfahrt Technik GmbH | View article |

Case Study: Rotary Wing MRO IT Case Study

Author: Jan Ketelsen, Manager Maintenance Planning, ADAC Luftfahrt Technik GmbH

Subscribe

Jan Ketelsen, Manager Maintenance Planning, ADAC Luftfahrt Technik GmbH shares the success story of installing and operating end-to-end ERP MRO solution for the Rotary Wing sector

ADAC Luftfahrt Technik GmbH (ALT)

ADAC Luftfahrt Technik (ALT) is an MRO business maintaining over 55 rotary wing aircraft. The company was founded in 1963 in Cologne, Germany as Air Lloyd, Deutsche Helikopter Flugservice GmbH. Initially operating as a crop dusting service in the vineyards of Germany and in Africa, the business maintained its own fleet of Bell helicopters. In 1970, Air Lloyd moved to its current base at St Augustine and started to maintain the Air Ambulances of ADAC (Germany’s main motoring organization) in 1983. ADAC became a shareholder in Air Lloyd in 1992 and bought the whole business in 1996. In order to better serve the ADAC Air Ambulances, two branch sites were established in Bavaria and Saxony. Since 1997, Air Lloyd has also provided maintenance services for aircraft of ANWB Medical Air Assistance, the Air Ambulance operator of the Dutch Automobile Association. At the outset, Air Lloyd was maintaining three MBB BO-105 helicopters whereas today the company has over 55 helicopters of varying types under contract. These are…

37 x EC135

12 x BK117

2 x EC145 and

4 x H145

In 2006, Air Lloyd started construction of its new office in Hangelar, near Bonn and, at the same time, was renamed from Air Lloyd Luftfahrt Technik (ALT) to ADAC Luftfahrt Technik GmbH (ALT). Today ALT employs more than 135 people across the technical and administrative spectrum, and is an EASA certified Part-145 MRO organisation and Part-21 design organization; plus it is an approved service center for Airbus Helicopters.

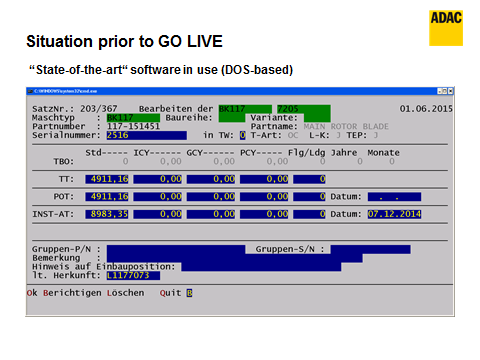

Situation prior to ‘go live’

IT wish list

A wish list of desirable outcomes and capabilities was assembled bearing in mind the expected business benefits to be gained from an MRO IT system; including anticipated benefits across materials, maintenance, planning, reliability and other areas. The fundamental concern in the research that supported the identification of the correct application was to achieve the realization of a comprehensive system that would satisfy the needs of all involved departments. The main focus was on hangar maintenance, logistics, sales, maintenance planning, procurement, stores, accountancy, staff and, if possible, the introduction of a barcode system. The secondary focus, but no less important, was the wish to realize modules covering quality management, document management, electronic time registration and accessibility to the application by customers. Project management, fleet management and performance management were set aside for the time being.

Expected materials benefits

There were some specific benefits that the business hoped to achieve in the materials division. These included:-

- Automatic replenishment of consumabe aircraft parts; this was identified as a quantum leap;

- The ability for materials forecasting and planning was a must;

- Improved and faster materials request processing was desirable;

- Improved repair order processing was also wanted;

- It was expected that the new solution should be able to manage vendors and suppliers;

- ALT was especially interested in improvements in stocktaking actions – at the time, taking stock was insufficient, people intensive and imprecise;

- And, last but not least, the business wanted improved monitoring of life limited parts.

Expected maintenance benefits

From a maintenance point of view, ALT also set targets that it aimed to achieve through a new software solution.

- As has already been mentioned, the prevention of paper accumulation was one of the most important enhancements sought;

- There was also a wish to achieve speed, accuracy and ease of work for everybody involved by linking part numbers to each single task on a task level;

- As maintenance staff were travelling to line maintenance stations located at hospitals throughout Germany and the Netherlands, the new application would have to be capable of using equipment for electronic signatures;

- All involved business units were aiming for standardization of reports;

- With regards to an external customer business, improved labor tracking was a must;

- It was particularly important to be able to differentiate between mechanics’ and inspectors’ skills through the sign-off;

- Finally, document linking capability was identified as an asset in order to have fast internet access to the manufacturer’s approved maintenance library.

Rotary aircraft maintenance in an air ambulance environment is challenging in areas such as ‘robbing’ components from one helicopter in order to install them in another one to ensure the availability of that helicopter. For this purpose, aircraft and component configurations defined in the application would enable the planning department to easily monitor parameters. Short-term and long-term maintenance planning activities should benefit from aircraft and component maintenance programs adapted to the manufacturer’s master servicing manual. ALT expected an improvement from the introduction of maintenance forecasts and the establishment of a fully functional ‘aircraft next due’ report. Reliability of data had to be achievable with a single data repository and single source entry of data.

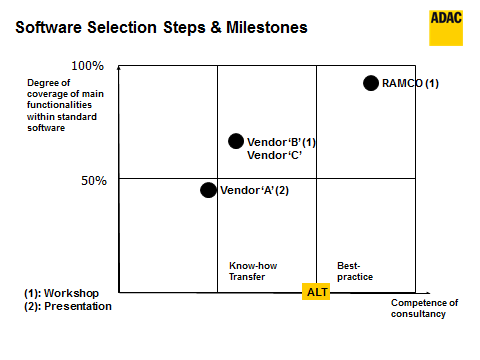

Software selection steps and milestones

Having established to its own satisfaction what qualities, capabilities and features were required in any new system, ALT management were now able to proceed to a software selection process based on that ‘wish list’.

In 2006, ALT conducted some market research from which 14 vendors who were supplying an appropriate MRO IT solution to match the above businesses requirements were identified. Requests for proposal (RFPs) were issued to seven of those vendors and, based on those proposals, four vendors were invited to product presentations and workshops.

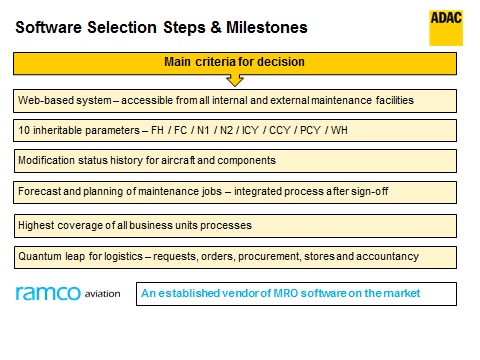

The benefits that had been identified as desirable or required from the new system were met by Ramco and their consultancy competence was impressive. Also impressive was the range of their applications across a number of business areas as confirmed with the experience of a number of their customers and users around the world.

Specifically, the factors on which ALT decided to go with the Ramco solution were:

- As a web-based system, the Ramco solution is accessible from all of ALT’s maintenance facilities;

- It offers the possibility of monitoring over 10 inheritable parameters, especially those for engine generator and turbine cycles, and for rescue winches – a specific issue with rescue helicopters;

- There is the ability to show a modifications status history for the aircraft and components;

- It facilitates the implementation of an automatic forecasted ‘maintenance due’ report;

- The solution offers high coverage of all business processes;

- The expected quantum leap for logistics in respect to material requests, orders, procurement, stores and accountancy.

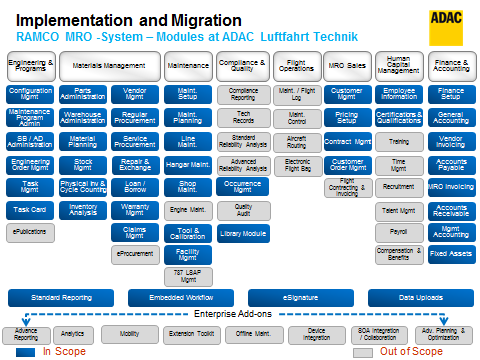

Implementation and migration

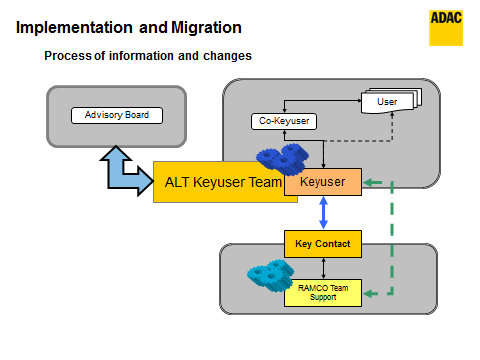

One fundamental element of the migration process was the formation of a qualified ‘key user’ team (see below).

The measured actual benefits after go-live

In terms of maintenance planning, the new system offers a high potential as all inheritable parameters are updated on the line and base stations and entered into the database over the Internet; also, all aircraft and component times are automatically kept up-to-date. This has an influence on the aircraft and component maintenance programs where, after issue of the electronic sign-off all related work units are scheduled to the next due value. The forecast is generated automatically in an overnight job by activation of an SQL (structured query language) scheduler routine. This provides an updated aircraft and component ‘next due list’ which is useful for maintenance planning.

There are some actual measured benefits that have been realized post go-live across materials, accountancy and maintenance. In the materials area ALT has achieved a 50 per cent time saving for initiating repair orders and over 99% stocktaking accuracy. Accountancy benefits have been realized from improved payments in different currencies and coherent processes for all business units. In the maintenance area, users have gained the ability for quick and easy searching of maintenance data and of related parts. The business is now able to make simple comparisons between estimated and actual man hours (a real plus with regards to external businesses) and has managed a 30% saving in the time taken for the preparation of maintenance events.

Future IT goals at the moment are to migrate to Ramco release 5.7 which is planned to go live in 2016. We understand the latest release is aligned more to the usability and accessibility perspective. We are keen to continue the relationship with Ramco and look forward to implementing and benefitting from the latest release.

Contributor’s Details

Jan Ketelsen

Jan Ketelsen is the maintenance planning manager of ADAC Luftfahrt Technik GmbH (ALT) responsible for preparing line and base maintenance events and for all maintenance and aircraft documentation. Prior to ALT, Jan worked as a maintenance planning specialist for Lufthansa CityLine GmbH where he was involved in various projects to improve base maintenance, implementing different ERP solutions and he is a licensed Airframe and Powerplant Technician with a degree as federally licensed mechanical engineering technician.

ALT

ADAC Luftfahrt Technik (ALT) specializes in maintenance and repair of aircraft and components. The company has tripled its turnover and number of employees since 1996 with about 130 employees today. Headquarters in Hangelar and two branches in Landshut and Halle-Oppin provide nationwide coverage in Germany for ALT’s services plus international customers are increasingly relying on the company’s technical expertise and reliability. High quality work and assured high availability for customers’ helicopters are ALT’s most important corporate objectives.

Ramco

Ramco Aviation Suite manages the entire business of aircraft maintenance covering engineering support, inventory and procurement, maintenance, sales and MRO contract management, compliance, quality, and operations. The company also offers an Off-Line Field Maintenance module targeted at organizations having remote aircraft operations with no internet connectivity. Ramco Aviation Suite is modular and specific functions such as Reliability Management can also be deployed as a standalone best of breed solution alongside existing systems.

Comments (0)

There are currently no comments about this article.

To post a comment, please login or subscribe.