Articles

| Name | Author | |

|---|---|---|

| Moving forward with a tablet EFB program | David B. Abbott, Director of Business Development, Avionics Support Group (ASG) | View article |

| Case study: Using a modern wind uplink | Bjorn Ostertag, Head of Fuel Efficiency & Punctuality Management, Lufthansa Cargo | View article |

| Case Study: Pegasus Airlines EFB: buy or build | Mehmet Akverdi, EFB Technical Admin, Pegasus Airlines and Capt. Korhan Celik, Assistant Fleet Manager, Pegasus Airlines | View article |

| Case Study: An iPad EFB Project at SmartLynx Airlines | Steinar Sveinsson, EFB Project Manager, SmartLynx Airlines and Jens Pisarski, COO, International Flight Support | View article |

| Getting the best from a paperless techlog | View article |

Case study: Using a modern wind uplink

Author: Bjorn Ostertag, Head of Fuel Efficiency & Punctuality Management, Lufthansa Cargo

SubscribeUsing a modern wind uplink

Lufthansa Cargo uses weather information to improve fuel efficiency: Bjorn Ostertag, Head of Punctuality and Fuel Management shares the project

Lufthansa Cargo (LH Cargo) has recently conducted and implemented an interesting trial and project involving a modern wind uplink solution. I’d like to share the experience with readers looking at three elements: an overview focusing on fuel consumption and costs in the Lufthansa group; The Aventus Nowcast system at the heart of this project; and the trial and evaluation process undertaken at Lufthansa Cargo, including weather analysis. But first I’ll give you a brief introduction to LH Cargo.

LUFTHANSA CARGO

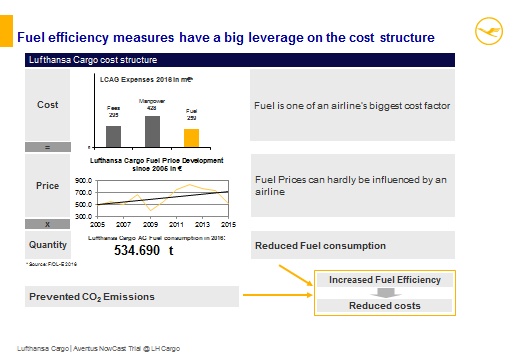

The airline has about 4,500 employees and a fleet of 17 aircraft – 12MD11F and 5 Boeing 777F – serving over 300 destinations world-wide. The business turnover is roughly €2.1bn each year with fuel costs amounting to € 259m or 20 per cent of all costs. Given that proportion of costs, fuel efficiency measures have quite a big leverage on the cost structure (figure 1). The mathematics are quite easy: price multiplied by quantity

Figure 1

FUEL CONSUMPTION AND COSTS

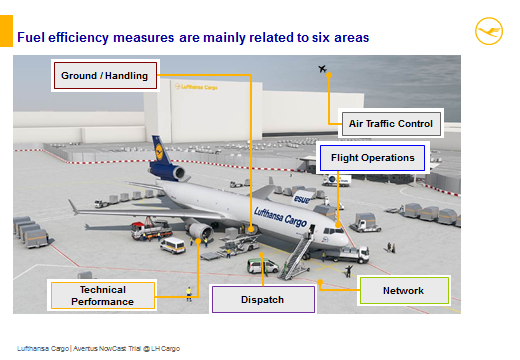

Of course, the price of fuel can hardly be influenced by the airline so, instead, it’s important to focus on the quantity of fuel consumed which is where the value of fuel savings can be realized. That can be both in increased fuel efficiency leading to reduced costs and, because less fuel is burned, it also reduces CO2 emissions. Lufthansa Cargo takes an overall view across six different fields where we try to find measures to be implemented and steadily improved on year-by-year (figure 2).

Figure 2

It starts with Ground Handling at the very beginning of the process because Ground Handling will determine the center of gravity (CG) and the trim which, of course, influences fuel consumption. Technical Performance is where the airline’s technical departments find and develop technical measures to improve the aircraft’s efficiency. Dispatch is responsible for flight planning with many small opportunities to save fuel, so their involvement in fuel efficiency is quite intense. Network might not, at first, seem a major contributor to fuel efficiency but Lufthansa Cargo works with the Network Department who determine block times, ground times; negotiate traffic rights etc. The contribution of Flight Operations is, perhaps, easier to understand with most airlines’ fuel efficiency departments being part of their Flight Operations. Finally, Air Traffic Control (ATC): LH Cargo has a good relationship with German ATC and meets regularly with them to discuss ideas as to how flight operations over German airspace might be improved.

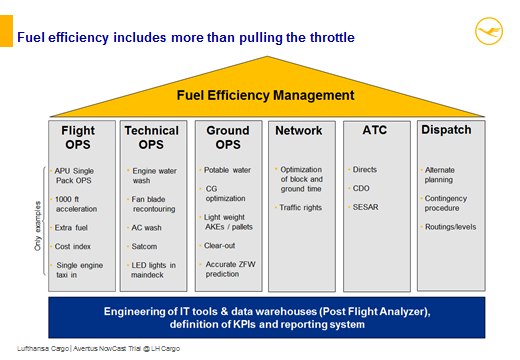

These are the six areas where fuel efficiency measures are generated and undertaken and, in figure 3, there are a few examples, without going into too many details, of what they can contribute.

Figure 3

Readers will certainly understand what lays behind these fuel efficiency measures.

Flight Operations

Calculating the correct cost index is an issue and something that LH Cargo does on a regular basis, individually for each flight – not a flat cost index per month or per city pair. Also, from the IATA fuel book, there are measures such as Single Engine Taxi that can be implemented.

Technical Operations

Technical Operations determines the frequency of aircraft washing and engine washing but even something like a fan blade re-contouring can improve the performance of an engine; so the airline decided to do that, even though it’s quite intense work.

Ground Operations

We’ve already looked at a couple of measures where Ground Operations can affect fuel efficiency. CG optimization is an important one but also, how precise is the Zero Fuel Weight (ZFW) prediction – the closer one can get with the ZFW prediction, the better the flight plan will be. LH Cargo also invests in its ULDs (Unit Loading Devices) with lightweight containers and pallets.

Network

Readers might wonder what ‘Traffic Rights’ have to do with fuel efficiency but, for example, if an aircraft enters Chinese airspace, it’s only allowed to enter at a certain waypoint and the airline has to have already secured clearance before the flight period has started so it’s a good idea to negotiate with the Chinese authorities as to which waypoint is the best one at which to enter Chinese Airspace.

ATC

This is a very broad field and it’s not only about Continuous Descent Operation (CDO) or ‘Directs’ over certain airspace. Through the SESAR (Single European Sky ATM Research) project, many things are being generated: for example, at the time of writing, there was the project called EMAS (Early Morning Arrival Stream) or iSTREAM (integrated SESAR TRials for Enhanced Arrival Management); Paris Charles de Gaulle was the first airport in Europe to trial this, Zurich followed and now Frankfurt is being talked about as the next. EMAS is about the sequence of arriving aircraft, especially in the morning, after the night ban has lifted, which will, of course, have an impact on fuel usage.

Dispatch

As mentioned above, Dispatch can influence many things. For example: contingency procedure – it’s not only about a 3% or 5% flat contingency and ‘has one protected or not protected?’ It might be better to analyze contingency but that’s not easy because a lot of data is needed; that said, there is the possibility to implement a procedure called Analyzed Contingency Fuel (ACF) and LH Cargo will be the frontrunner here within the Lufthansa Group.

AVENTUS NOWCAST

Having taken an overview of the big picture, I will now focus down on one issue that has been engaging LH Cargo during the past twelve months (at the time of writing) with a trial to get some more precise wind data into the aircraft. The history of this started five years ago when I started to take over the Fuel Efficiency department and heard from pilots that they wanted more precise wind data because there is so much potential in it. It actually took a while before the airline could take that step but in 2016 it was started. LH Cargo does not use data from DWD (the German Weather Service) anymore but uses the wind data from the UK’s Met Office which has the advantage that it works on a 10km grid, as opposed to the 140km grid used by most weather services, and with many more levels, which makes Met Office data very precise.

How it works is that the Avtech tool Aventus NowCast communicates directly, via datalink, with the Flight Management System (FMS) of LH Cargo’s aircraft; it wasn’t necessary to set up any specific IT tool or interface which made the job quite easy and not complex to use. Messages are sent automatically to the aircraft and the pilot has only to ‘accept’ with a single click for the wind data to be uploaded into the FMS which then has actual wind data available in order to calculate the next flight trajectory. Wind data can also be requested manually by the pilot at any time.

Here’s the theory where some fuel saving should come from. Usually there are standard levels where one gets wind data from different providers but it’s normally levels 100, 200, 300 or 100,180, 240; and, no matter what the weather situation is, it will always be wind data for these flight levels in the FMS. However, it’s very unlikely that any changes to wind will fit exactly into these levels so Avtech applies an algorithm to those levels that are needed for that flight and for the profile. The aim is to reduce wind error. Of course, in the real world it will never be the precise wind being loaded into the FMS but if the error level can be reduced, the more accurate the wind loaded into the FMS is, the better the FMS is equipped to determine the trajectory. Both on the Avtech database and in the FMS there are procedure constraints plus the FMS will always follow these procedure constraints to move the top of the descent and the vertical speed to that which is most efficient.

That’s the theory and, over the last year, LH Cargo tested that to discover whether there really are savings available. So, how did that trial work?

TRIAL AND EVALUATION

LH Cargo started a ten month trial of Avtech’s Aventus NowCast from November 2016 until August 2017 using the twelve aircraft in the MD11F fleet operating all around the world; there was no focus on any particular city pair or airport so that a broad database could be generated. One reason that the trial took so long was that we didn’t wish to focus on one specific month but to conduct the trial over a longer period. Especially between February and April 2017, all FDM in-flight data was collected. LH Cargo has a tool to collect FDM data and to measure and monitor the results of any fuel efficiency measures. The trial covered more than a thousand flights that could be analyzed in detail, which entailed quite a lot of manual work but it was felt that the large number was needed in order to be sure that it wasn’t just a single week or a single flight that gained some saving.

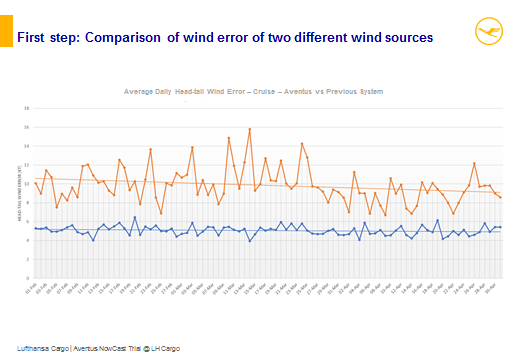

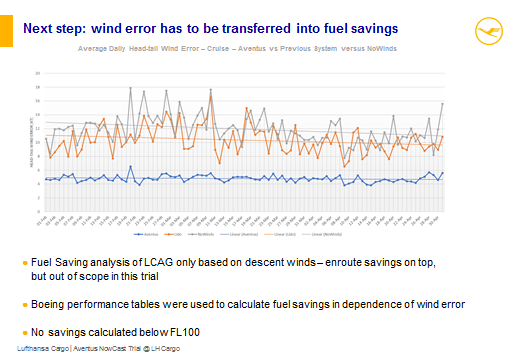

The first step was to compare the wind error of two different wind sources (figure 4).

Figure 4

Figure 4 shows the wind delta during cruise: the blue line shows the error levels from the new wind uplink while the yellow line shows the equivalent error levels using the old system. It’s quite obvious that the level of error between the actual wind encountered and what had been loaded into the FMS is lower with the new wind uplink; there’s still some error but it is a definite improvement. Also, the quality of the data is not as volatile as it was with the old system.

The second step was to investigate wind delta during descent which generates more or less the same outcome (figure 5).

Figure 5

The challenge now was to translate those improved and more consistent levels of wind error into fuel savings and LH Cargo used the manufacturers’ performance tables which take weight, temperature and altitude into account: from there, it’s possible to calculate a fuel penalty between the wind error and the fuel used. We then decided, for our business case, that we would take fuel savings during descent into account, but neither during cruise nor during final approach, below flight level 100 (figure 6).

Figure 6

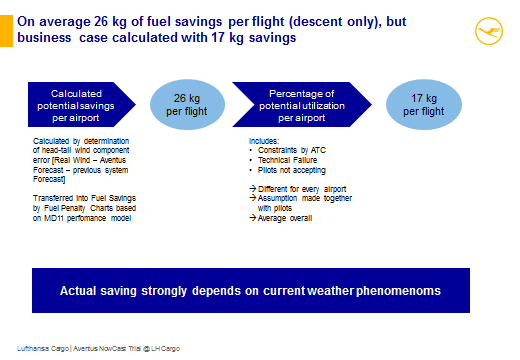

On average, the fuel savings during the trial amounted to 26 kilos per flight and some might wonder whether that was a lot of savings. However, there are only a few single measures that would generate savings of more than 50 kilos per flight, so 26 kilos was a satisfactory saving per flight.

It was decided that, for the business case, a more conservative figure should be used. So a calculation was done which gave the various figures a weighting because Frankfurt showed a different average fuel saving compared to Dakar and JFK; it was also taken into account that not all pilots would use the tool or a technical problem meant there was no wind uplink. The outcome was a saving figure for the business case of 17 kilos per flight to be sure that, over a whole year using this tool, there would be some substantial savings to be realized.

Interesting there were quite large variations including some days when there were hardly any fuel savings and others when quite large fuel savings were realized. The reason behind this, we learned, was a dependency on the current weather phenomena.

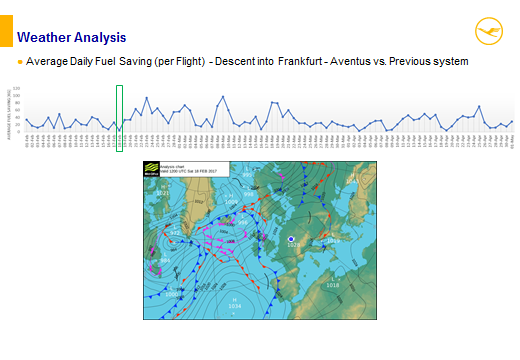

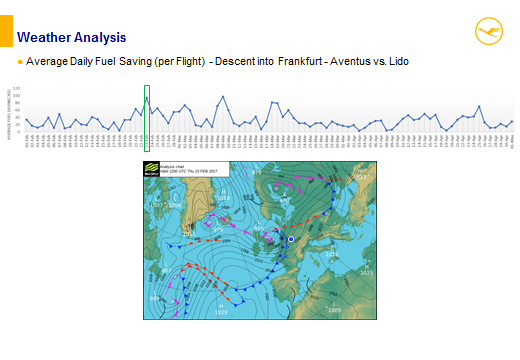

WEATHER ANALYSIS

Figure 7.1 is a graph showing the average daily fuel saving per flight for the descent into Frankfurt. The map is a typical one but, of course, would differ for every day during the period.

Figure 7.1

The blue line in the graph records the fuel saving in kilograms and it can be seen that there were days when there was hardly any fuel saving while there were other days when the fuel savings were huge. The map shows the weather situation on one day (in this case, 18th February, a zero savings day) with the focus on Frankfurt (blue dot on the map) because the majority of LH Cargo’s descents are into Frankfurt. On that day, as the chart shows, the weather was stable over Frankfurt.

The next day (19th February) the weather changed (figure 7.2) becoming rougher over Frankfurt and the fuel saving increased…

Figure 7.2

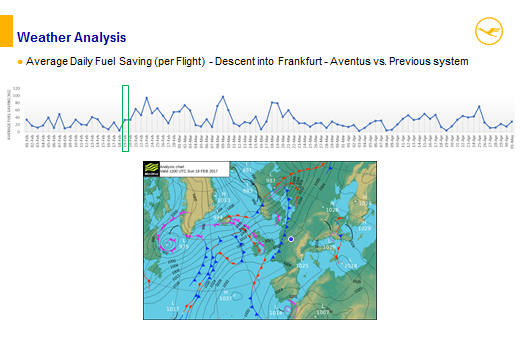

… then on 23rd February (figure 7.3), it was very unstable weather over Frankfurt so that the fuel saving went up significantly.

Figure 7.3

The fuel savings depend very much on what the weather situation is and, of course, it’s not possible to predict what the weather will be like next year which is one of the reasons why LH Cargo assumed only 17 kilos per flight saving on average. The project has entailed twelve months of intensive work, at the end of which LH Cargo decided to use the Aventus wind uplink on all of the MD11F aircraft and on the Boeing 777F fleet as well. Furthermore, other airlines within the Lufthansa Group are looking at what LH Cargo is doing. That said, the implementation work will have to be per tail sign because it’s necessary to change the SITA address for where the data is sent but, step by step (tail by tail), the new system will be implemented across several airlines of the Lufthansa Group.

Contributor’s Details

Bjorn Ostertag

Bjorn OstertagBjorn Ostertag is currently with Lufthansa Cargo in the position of Head of Fuel Efficiency & Punctuality Management. His career with Lufthansa group started with his apprenticeship while studying for Master’s degree in Business and Commerce at University of Hagen and Frankfurt. His responsibilities within the company varied from brand evaluation, multilateral pricing, airport services and ground handling. The latter project was Bjorn’s position prior to the current one – the Head of Aircraft Ground Handling in Frankfurt within Lufthansa Cargo.

Lufthansa Cargo

Lufthansa Cargo

Lufthansa Cargo ranks among the world’s leading air freight carriers. The carrier serves around 300 destinations in approximately 100 countries with its own fleet of freighters, the belly capacities of passenger aircraft operated by Lufthansa, Austrian Airlines and Eurowings, and an extensive road feeder service network. As of August 2017, the Lufthansa Cargo fleet consisted of 12 MD11F and 5 Boeing 777F aircraft.

Avtech

AvtechAVTECH is an innovations company that assists the global air transport industry to optimize operational efficiency and capacity by offering unique and sustainable solutions combining leading edge technology and industry expertise with a human and environmentally friendly approach. AVTECH’s solutions are based on modular, patented platforms which enable different services depending on how the modules are combined.

Comments (0)

There are currently no comments about this article.

To post a comment, please login or subscribe.