Articles

| Name | Author |

|---|

Case Study: Using data for fuel efficiency at Cebu Pacific

Author: Francesc Torres, Director Flight Operations Technical Support & Dispatch, Cebu Pacific, and Alexandre Feray, CEO of OpenAirlines

SubscribeUsing data for fuel efficiency at Cebu Pacific

Francesc Torres, Director Flight Operations Technical Support & Dispatch at Cebu Pacific and Alexandre Feray, CEO of OpenAirlines explain how a fuel preservation program was implemented at Cebu Pacific

ABOUT CEBU PACIFIC

In this article we will cover how Cebu Pacific established its fuel program and how it’s not necessary to be a large airline in order to set up a successful fuel management program. Fuel represents the largest single expense for any airline which means that it is very important to work at managing and, through that, reducing the volume and cost of fuel used.

Cebu Pacific airline is based in the Philippines and operates long-haul international flights (including to the Middle East and ETOPS services) as well as an extensive domestic network. It makes for an often complex operation. There are currently 60 aircraft in the fleet with another 50 on order which will take the fleet to about 100 aircraft (mainly Airbus and ATR types). With some 10,000 flights a month, Cebu Pacific carries around 20 million passengers a year.

FUEL OPTIMIZATION PROGRAM

The approach

Cebu Pacific didn’t want to dictate to pilots how they should perform their job as far as fuel is concerned; there was no wish to force them to do any of the procedures required. Rather the airline wanted to change the company culture to one that is fuel conscious, where everybody understands that fuel is a limited and costly resource. So, where to start?

There was no previous experience of fuel management in Cebu Pacific prior to this project nor any experience of ‘Big Data’ but Cebu Pacific is growing fast and needed something that would be easy to implement and quick so that it wouldn’t be necessary to spend multiple years achieving the desired company culture. The first step was to define a road to success, how the airline was going to get to the final objective and the first requirement in that was communication to the operational staff that was continuous, concise and transparent – easy for everybody to understand from pilots to ground staff to management; right across the organization. It was also important to define objectives and KPIs (key performance indicators); to measure them and to evaluate their success openly so that if something was not working, it could be changed. However, to do all that, data was needed, in pursuit of the end point which would be a company culture where everybody was conscious about fuel. It’s a limited resource, it’s not feasible to simply burn as much fuel as we might want but, within that, safety and efficiency cannot be compromised.

Starting with big data

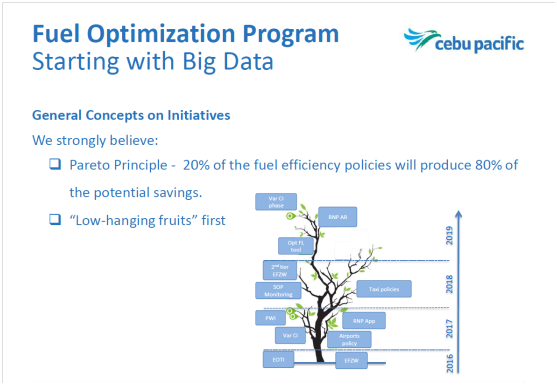

Cebu Pacific’s program is predicated around two basic concepts (figure 1). First is the Pareto principle1 that twenty percent of actions taken will account for eighty percent of outcomes. In this case, it means that twenty percent of fuel efficiency initiatives should account for eighty percent of fuel savings which leads to the question, ‘what are those twenty percent of initiatives?’ They vary from company to company but largely (and this is our second basic concept) they could be described as the ‘low hanging fruits’; those changes that it will be easier to implement and that everybody in the process will understand so that it’s possible to get momentum into the program. The problem with things that are very complex and need years to implement is that, if they’re the first initiatives in the program, they’ll never be completed.

Figure 1

The first challenges in all of this were that Cebu Pacific was starting with Big Data. So there was the challenge of data availability. A lot of readers will still operate a lot of manual processes with paper and manual input which, when embarking on a fuel management program based on data, poses the challenge of how to get all of that information into an electronic format and how to get it into the system so that it’s possible to analyze what is going on for Operations. There was also the challenge of generating positive information feedback; establishing KPIs, measuring them, analyzing them and, where necessary, biting the bullet and modifying them if they didn’t contribute anything useful to the program or if the information they deliver is not really needed.

Culture and communication

It’s necessary to look at data objectively: data is not generated to apportion blame, KPIs are not measured to judge people; the objective is to improve what we do using real information to view outcomes objectively. In some airline cultures, people are sensitive about ‘pointing fingers’ but that should never be the way data and KPIs are used. If that is an issue, it will be necessary to first change the company culture so that people see KPIs as a positive resource to help them improve the process and perform their job better.

An important part of the road to success is to get all the big data and all the KPIs, yes, but, as important is how are they displayed, how are they measured, how is the database built? This is where Cebu Pacific looked for a partner to work with them in developing the program and chose OpenAirlines.

HOW OPENAIRLINES’ SKYBREATHE CAME TO HELP

Collecting data

In reality, airlines have, for a long time, been sitting on a mine of data: their problem is that they are data rich but information poor. However, in order to make good decisions and improve processes and performance, companies need information based on data not just opinions based on experience. The good news is that, with modern technology, advances in IT technology and so-called big data technology there are now the means available to exploit all of that data and turn it into information. OpenAirlines has designed a sophisticated IT system that processes a lot of data and turns it into information about fuel efficiency. In the case of Cebu Pacific, the fuel efficiency software had to interface with and integrate data from seven different sources:

1. QAR (quick access recorder) data was used extensively;

2. OFP (operational flight plan);

3. AOC (airline operation control/center);

4. ACARS (Aircraft Communications, Addressing and Reporting System);

5. Load sheets;

6. Fuel prices;

7. Active Diretory (authentication infrastructure).

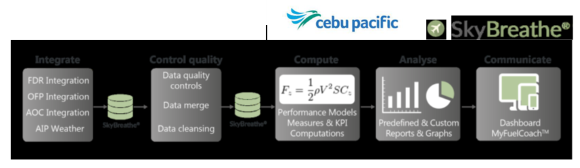

This process (figure 2) includes merging the data, cleansing it (there will often be mistakes in the sources) and, most importantly, interpreting the data. At Cebu Pacific, the seven different sources generate some 2 gigabytes of data each day so it’s not a simple task to turn those data into information. Having done that, it’s then important to have a clear communication of the data and information in order to ensure that decisions are based on correct and correctly understood information.

Figure 2

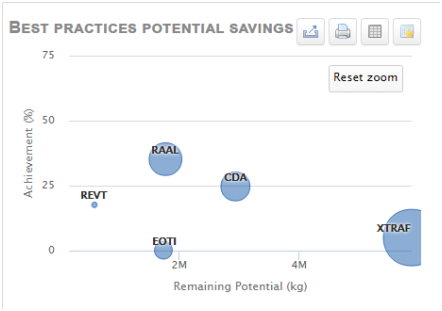

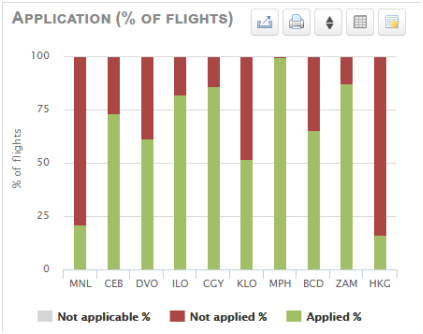

Delivering information

When users log into the software, the first thing it tells them (figure 3 and figure 4) is where they can save fuel, what are those ‘low hanging fruits’ that we mentioned earlier. As can be seen, the potential savings are huge. And having seen these automatically generated global figures, users will wish to drill down to see how they apply to each aircraft type in the fleet, to each route, at different airports, etc. to see where specific changes can be focused to achieve progress on fuel management.

Figure 3

Figure 4

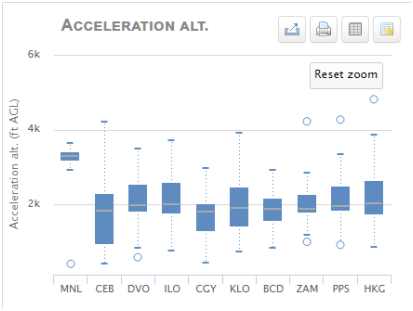

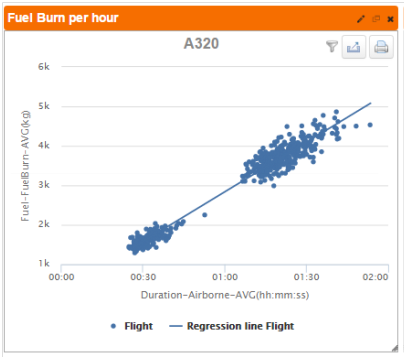

Of course, not all fruits are ‘low hanging’. There are also ‘higher hanging fruits’ which are attractive and can deliver real value but which cannot so easily be reached. In the matter of fuel efficiency, users will need a software solution to exploit these ‘higher hanging fruits’. For Cebu Pacific, the OpenAirlines SkyBreathe solution offers the sophisticated levels of measurement for KPIs and metrics that is required. Figures 5 and 6 illustrate examples of the type of information needed to leverage these higher level savings potentials.

Figure 5

Figure 6

As can be seen, information can be broken down so that, for instance, data such as Acceleration Altitude can be recorded for different airports in order to allow the airline to maximize the realizable savings in all situations. Users can drill into the information by many different criteria in order to find where all the savings can be realized. But, if users want to get to the ‘higher hanging fruits’, these types of tools are required.

Building an inclusive culture; spreading the word

Coming back to another earlier point, it is so important to build the right company culture. If the full value of any fuel management program is to be realized, there must be a fuel conscious culture throughout the company; maintenance, ground support, flights ops… and, for that to be the case, it is important to communicate. The software also helps here because SkyBreathe allows users to build their own custom dashboards with the KPIs they want. There can be dashboards for maintenance, for flight ops, for everybody; plus the software allows those dashboards to be shared easily (on a public or a restricted basis) on the Internet. There’s also an iPad app for pilots that, after each flight, provides a debriefing on each aspect of fuel management during that flight so that pilots feel engaged in the process and can apply their own professional skills to improve fuel efficiency on later flights. It’s not to check on them but to give them the information with which they can best do this part of their job, understand what fuel efficiency is about and make progress.

And finally, it’s a good idea to take the culture of fuel consciousness beyond the company even by engaging with the local ATC (air traffic control) authority. Perhaps their approaches are designed well for safety and for noise minimizing but take little or no account of fuel efficiency. Again, with the tool, an airline can create some analyses based on real data which will make it possible to present facts and figures to the ATC authority as the basis for a dialogue; some airlines have already done this.

CHALLENGES THAT HAVE INFORMED THE PROGRAM

The challenges encountered during Cebu Pacific’s fuel efficiency program and from which the airline has learned have included:

- Crew culture: for each airline it will be different but it’s important that the people designing the fuel efficiency initiative understand this in order that they can evaluate the best way to communicate with crews and integrate them as active participants into the program.

- Organizational change: it’s important to be transparent so that users can see for themselves what is happening.

- Collecting data: with so much data to put into the system, so many paper processes to change and the need to ensure accuracy, it does take time; so people have to be patient when the system is being established.

- A special team for the program: don’t just tag this on to other jobs; make it a role in its own right with a team who understand the challenges, the issues to target, the resources available and how to get the best from the system.

In this way, an airline can get to grips with the issue of fuel and can also use that program to support staff engagement in the good running of the business.

Notes

1 The Pareto principle is a principle, named after economist Vilfredo Pareto, which specifies an unequal relationship between inputs and outputs. The principle states that 20% of the invested input is responsible for 80% of the results obtained. (Investopedia.com)

Contributor’s Details

Francesc Torres

Francesc Torres is Director – Flight Operations Technical Support & Dispatch at Cebu Pacific, supporting Flight Operations in all related technical matters, including Fuel, performance, documentation, flight dispatch, delivery flights. His companywide duties include migrating flight operations to Data-driven decision making, using Big Data Analysis tools. Francesc holds degrees, in Aeronautical Engineering and in Management and Business Administration. Currently living in the Philippines, he is a Spanish national and speaks fluently English, Spanish and Catalan.

Alexandre Feray

Alexandre Feray, the CEO of OpenAirlines, has 25 years’ experience in the Software and Airline Industry. He holds an MSc in Engineering and IT from École Centrale Paris and started his career at IBM before joining Alcatel and Air France, where he was the head architect of Air France Operations Control Center’s reengineering program and became the head of Air France Crew Management IT Department. In 2006, he founded OpenAirlines, providing consulting and software solutions to reduce the costs of the airline operations.

Cebu Pacific

Cebu Pacific, is a Philippine low-cost airline based in Manila. It offers scheduled flights to both domestic and international destinations. The fleet is comprised of 48 Airbus (6 A319, 36 A320 and 6 A330) and 9 ATR (8 ATR 72-500 and 1 ATR 72-600) aircraft. It is one of the most modern aircraft fleets in the world. Between 2016 and 2021, Cebu Pacific will take delivery of 32 brand-new Airbus A320, two Airbus A330, and 15 ATR 72-600 aircraft.

OpenAirlines

Leveraging a team of airline specialists and data scientists, OpenAirlines offers innovative software solutions to save fuel (SkyBreathe®), manage crews (CrewIntelligence™ and CrewPad™) and fleet (OptiFleet™). Capitalizing on its participation in the European Research Program, Clean Sky, from 2009 to 2014, the company developed SkyBreathe®, an innovative eco-flying solution to fuel saving and reduce CO2 emissions. OpenAirlines devotes more than 25% of its turnover to R&D leading to more fuel saving and a better ROI (return on investment) for users.

Comments (0)

There are currently no comments about this article.

To post a comment, please login or subscribe.