Articles

| Name | Author | |

|---|---|---|

| White Paper: Continuing Improvement through Process Modelling and Adaption | Peder Falk, Aviation Systems Professional, Aviro AB | View article |

| Case Study: A Look inside manage/m | Dr. Falk Kalus, Director of the manage/m® division, Lufthansa Technik | View article |

| White Paper: Business Analytics for the Airlines MRO Industry | Lakshmi Narasimhan, Assistant Vice President – Travel & Transportation, and Sunil Joshi, Subject Matter Expert, Hexaware Technologies | View article |

| Case Study: New IT for MRO, the build or buy dilemma for AirAsia | Juswil Adriani, MRO Liaison Engineer, AirAsia | View article |

| White Paper: Mobile Device Considerations for Supply Chain and ERP Related Systems | Byron Clemens, President/Principal Consultant, CKK Solutions | View article |

| Case Study: Getting the right people in the right place for each job on the schedule | Dr. Orkun Hasekioglu, CIO, Turkish Airlines Technic | View article |

White Paper: Business Analytics for the Airlines MRO Industry

Author: Lakshmi Narasimhan, Assistant Vice President – Travel & Transportation, and Sunil Joshi, Subject Matter Expert, Hexaware Technologies

SubscribeBusiness Analytics for the Airlines MRO Industry

It’s not only the quality of the data available but also the capability of the system handling and delivering it that will support a busy MRO operation, explain Lakshmi Narasimhan, Assistant Vice President – Travel & Transportation, Hexaware & Sunil Joshi, Subject Matter Expert, Hexaware.

1. Introduction

In recent times, the airlines are facing many challenges with operations mainly due to rise in fuel, maintenance and labour costs. With operational margins falling sharply and bottom lines are in red, the pressure for faster turn-around time of their aircrafts is a priority without compromising on the safety standards. Despite these challenges, the potential to improve data recording, storage, retrieval and use in Maintenance, Repair and Overhaul (MRO) organizations is promising.

It is estimated that the world’s airline fleet will grow by 45% over the next 10 years while the MRO global market will grow by US$10 billion over the next five years. Solid growth in new airlines, aircraft fleets and passenger numbers, both in developed and emerging economies (particularly China and India) is adding to the demand for MRO services. The newly introduced aircrafts, the Airbus A380 and Boeing 787 Dreamliner are certain to introduce new standards, processes and tools to the sector. This will add more complexities of MRO processes and the operational information needed to optimize maintenance processes and labor costs. The geographic spread of MRO facilities (including new facilities in Asia Pacific) poses new challenges when integrating data, customers, suppliers and IT systems for operational information purposes.

Efficient and excellent Business Intelligence and Business Analytics are the need of the hour to overcome these challenges.

2. MRO systems complexities

With the continuing proliferation of a mixed bag of IT systems, airline companies or MRO outsourcers are not geared to integrate operational data and add value to it by transforming it into business information, either for process operation analysis or for parts inventory optimization. Airlines with 100 or more aircraft on the fleet can typically hold inventories of 200,000 or more parts in the store. This, includes, high priced items like engines, landing gear, auxiliary power units (APUs) and other major items of equipment. Most of these parts have long life spans resulting in very high lifetime maintenance costs compared to initial purchase cost. Last but not least, proper planning of man hours and material requirements (parts and tools) in respect of each task for the time when maintenance procedures are carried out will also help to predict, manage and reduce maintenance costs.

3. The traditional approach

Most of the leading MRO software solutions provide standard reports and queries. None of them help the Maintenance and Engineering (M&E) section to identify areas where there is potential for better service delivery or cost saving. This results in a huge additional effort generating ad-hoc reports, identifying queries and data extraction to spread sheets. Mainframe based MRO software packages generate reports (standard as well as ad-hoc) in batches. This means that the end user has to wait for hours and sometimes a week to receive the report before they can even begin to act on it.

4. Taking a different approach

The modern approach, supported by business intelligence and analytics (BI&A) tools, enables M&E to build information entities for decision support; extract, cleanse and load data; build a data warehouse, and drill down the data to get desired maintenance information. Building the data warehouse is a one-time effort, after which the end user can then generate the reports they need in the way they want using the tools provided. The major advantages of this type of BI&A system are:

- It supports preventive maintenance planning and on-time flying;

- Desired data are readily available;

- Queries and reports can be generated in any permutation and combination;

- It delivers high data visibility;

- It helps engineering management to take quick decisions based on recent data;

- It reduces IT costs;

- It is a paperless process.

Taken together, the above translate into achieving the key MRO objectives of enhanced airworthiness, high reliability, cost-effective maintenance, preventive maintenance planning and on-time flying.

5. The source of data on which MRO service decisions are made

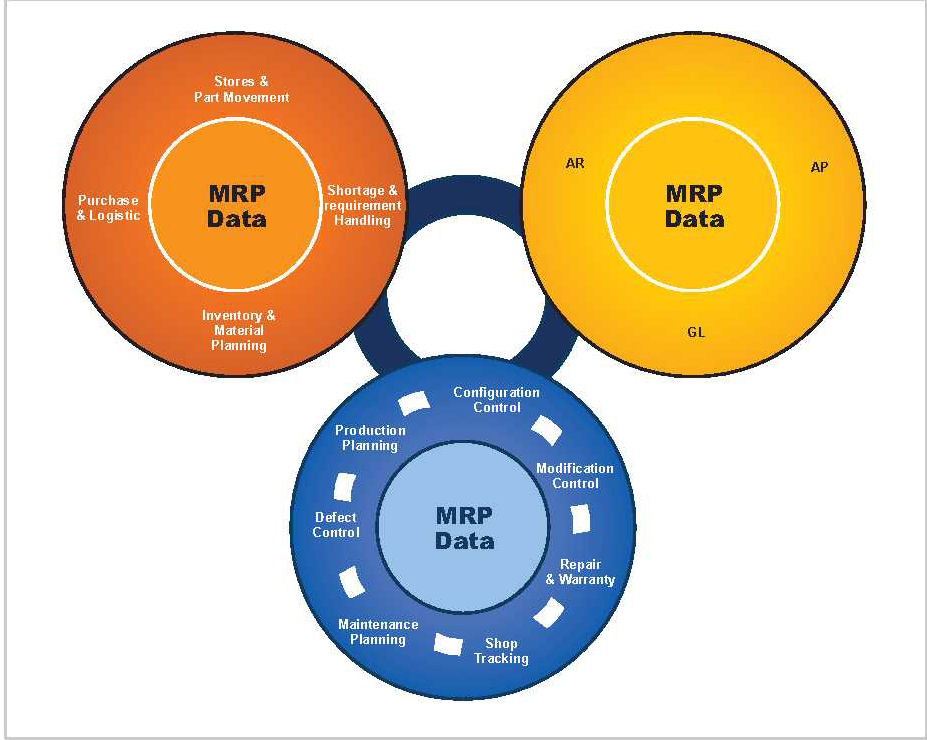

The data is supplied by multiple main materials requirement planning (MRP) and MRO modules such as, Configuration Control, Maintenance Planning, Technical Records, Repair and Warranty, Workshop tracking, Defect Control, Production planning, Digital Documentation, Material planning, Purchase & Logistic, Projects, Inventory & Stores control, interfaces with other systems and invoicing. Some of the data generated are operation critical and required for forecasting and trend analysis.

Aircraft configuration records are specific for each aircraft and they will include records of install and removal events, repair and warranty, defects, long and short term maintenance requirements, and completion records. Apart from this, many data from satellite systems like DMS and RMS are also captured. So, considering the type of data, crucial information is captured which is required for quality assurance (QA) and for submission to the regional Directorate General of Civil Aviation (DGCA). The accompanying figure 1 sets out the data source perspective.

6. Data warehouse (DW) is the solution

A data warehouse (DW) is the optimum solution for the massive MRO data analyses required to support decisions for Information Services. The solution offers flexibility for management and end users to review the historical data and take quick business decisions. It also reduces IT development costs. A fundamental concept for a data warehouse is the distinction between data and information. Data are composed of the sort of recordable facts often found in operational or transactional systems. In a data warehouse environment, data only comes to have value to end-users when it is organized and presented as information. Information is an integrated collection of facts and is used as the basis for decision making.

The data warehouse is that portion of an overall architected data environment that serves as the single integrated source of data for processing information. A data warehouse has specific characteristics that include subject orientation; it is an integrated source of information; it is also non-volatile, time variant, accessible and process oriented.

7. An approach to building a data warehouse and potential challenges

The first step is to identify the decision support information requirements and the sources of the subject oriented and non-volatile data. This needs to be discussed and agreed with the departments concerned – a process that requires the collaboration of end users and IT consultants to arrive at the comprehensive and business specific requirements. While creating the requirements, designers should be specific on particular subjects or areas of interest, not simply as computer files. Designing a data warehouse demands many steps including the creation of universes, classes and objects; mapping requirements with data; establishing table joins; deciding on summaries and aggregates; indexing; and categorizing. It also includes deciding on aggregating techniques such as Star Schema and Snowflake Schema, and deciding on the target data base, tables and their relationship.

The extraction of data from the operational environment to the data warehouse environment requires a change in technology. Often the selection of data from the operational environment may be very complex. Due to diverse technology platforms, multiple data sources and data inconsistencies, data has to be integrated, reformatted and cleaned before populating the data warehouse. The ‘extract, transform and load’ (ETL) operation must account for massive volumes of input from the operational databases. Data relationships that have been built into old legacy program logic must be understood and unraveled before those files can be used as input.

Developing data warehouses for specific areas is a very complex process. That complexity increases when a legacy system is involved as the source. Especially in the MRO space, most systems are legacy based and have to interface with many other external systems such as enterprise resource planning (ERP), resource management system (RMS), docket management system (DMS), engine monitoring systems, aircraft communications addressing and reporting system (ACARS), flight scheduling, etc. There are many MRO operational sections, and the skill set and expertise of end users will differ from one section to another. So, before initiating any data warehousing activity, a clear idea of the MRO domain is essential plus active involvement of the users is required: otherwise, the desired result may not be achieved.

8. Conclusion

In summary, inefficient MRO and M&E services not only incur high MRO costs but also severely impact airlines through delays and lost revenue opportunities. The impact on the corporate bottom line quickly becomes obvious. Also the number of aircraft in an operation multiplies the impact. Investment in new BI&A technology coupled with judicious outsourcing of the data warehousing development and integration projects, will certainly yield high returns.

Comments (0)

There are currently no comments about this article.

To post a comment, please login or subscribe.