Articles

| Name | Author | |

|---|---|---|

| White Paper: Continuing Improvement through Process Modelling and Adaption | Peder Falk, Aviation Systems Professional, Aviro AB | View article |

| Case Study: A Look inside manage/m | Dr. Falk Kalus, Director of the manage/m® division, Lufthansa Technik | View article |

| White Paper: Business Analytics for the Airlines MRO Industry | Lakshmi Narasimhan, Assistant Vice President – Travel & Transportation, and Sunil Joshi, Subject Matter Expert, Hexaware Technologies | View article |

| Case Study: New IT for MRO, the build or buy dilemma for AirAsia | Juswil Adriani, MRO Liaison Engineer, AirAsia | View article |

| White Paper: Mobile Device Considerations for Supply Chain and ERP Related Systems | Byron Clemens, President/Principal Consultant, CKK Solutions | View article |

| Case Study: Getting the right people in the right place for each job on the schedule | Dr. Orkun Hasekioglu, CIO, Turkish Airlines Technic | View article |

White Paper: Continuing Improvement through Process Modelling and Adaption

Author: Peder Falk, Aviation Systems Professional, Aviro AB

SubscribeContinuing Improvement through process modelling and adaptation

A thorough approach at the start of a project, says Peder Falk, Aviation Systems Professional at Aviro AB, will ensure a better project and a better installation

Peder Falk, Aviation Systems Professional, Aviro AB

Growing numbers of organisations are realizing the importance of performing a complete business process mapping project in order to better understand the current position for the business’s processes and to be confident that workflows are as streamlined as is possible. The objective is to ensure that the business works through well-defined processes that add value for the organisation, minimise the use of time consuming manual inputs and produce optimum feedback to management about routine operations.

The reason for including manual inputs is that most systems in daily use have to interact with each other through different standards which require manual intervention and, since a manual input is always a risk, such transactions should, if possible, be minimized.

As always, as your MRO IT system becomes increasingly complex, the more important it is that you establish greater control over its various features. Adding system flags into your business process models will provide you with a graphic overview of where the system should support you with information as well as receiving information from an outside source.

I’ve seen many examples of MRO IT systems being used only to a limited extent, instead of their full capability being utilised. This is usually because many implementations focus on a quick introduction of the system, rather than mapping the company’s needs against the methodology on which the system is based. With an implementation like that, it very soon becomes apparent that there are frequent requests, from the people and resources that use the system, for new reports and new data exports: however, these requests are too often made in an uncoordinated manner as a perceived need arises. This reactive approach is because no prior thought has been given to structuring defined ways to distribute information: there hasn’t really been any thought as to how to get something valuable out of the system; only that some data must be put into the system.

It would be more constructive to think more ‘what output will I have from the software’ rather than ‘how can we put this into the software’, since most software operates in the same way for inputs, while there are considerable variations when it comes to outputs and automation. That question about outputs is, of course, part of a current situation analysis and the creation of a list of demands for your MRO IT system (current or future), but it’s also worth mentioning in this context.

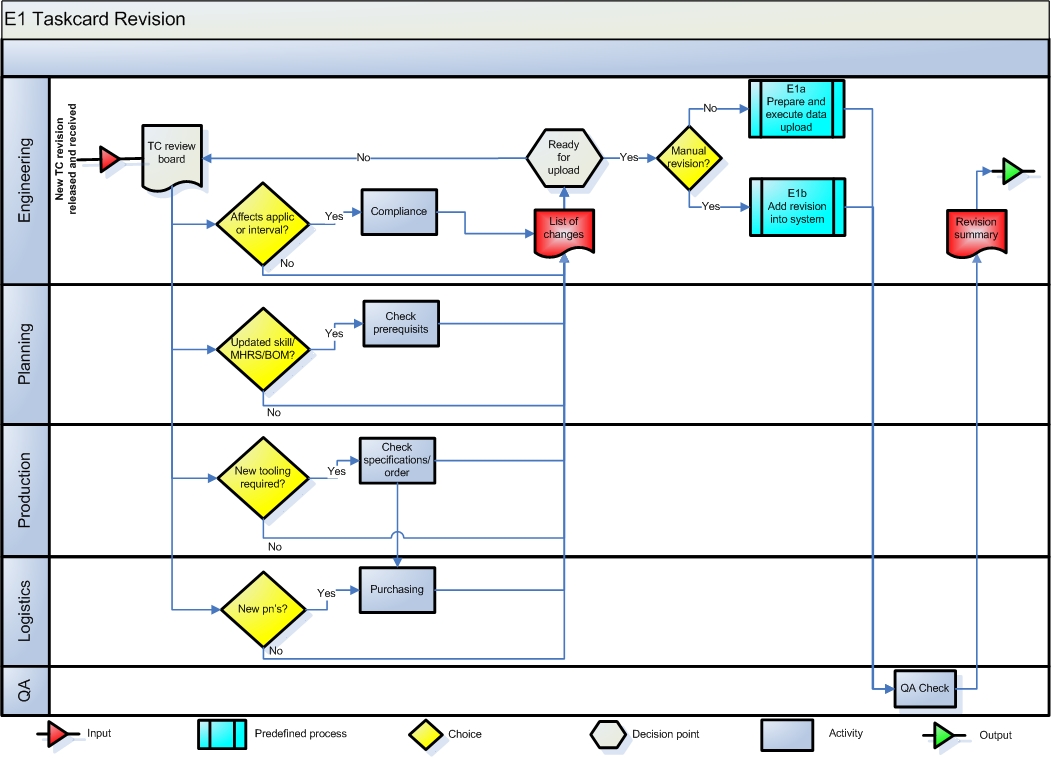

Figure 1

One important thing to bear in mind when it comes to considering processes is the idea of defining customers. Everything that you do will, in the end, produce a result, an output on which someone else is depending; either a person working in the same business (an internal customer) or a person or resource working at another company or organisation (an external customer). The focus should always be on customer needs and satisfactory usage.

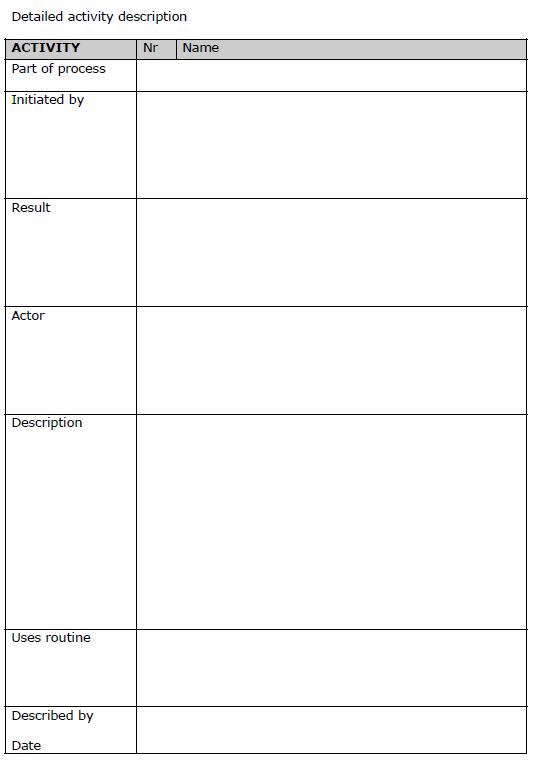

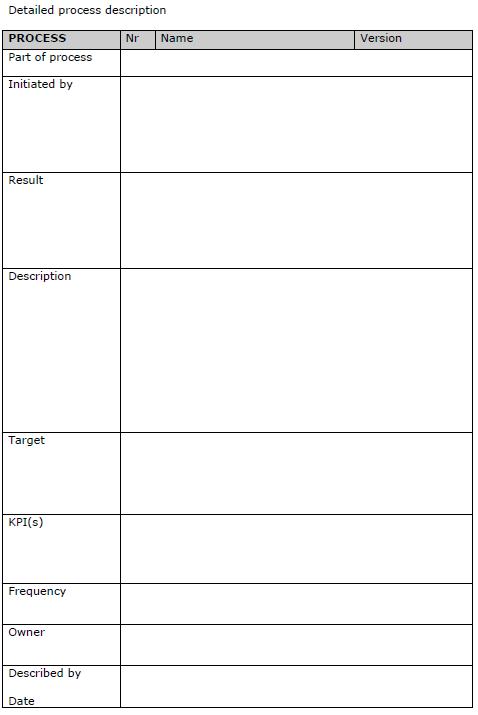

Figure 2

It’s very much the same as when implementing ITIL (IT Infrastructure Library) for an IT Services supplier, the purpose is to offer services to internal and external customers and then measure how well you perform by regularly checking your KPI’s (key performance indicators) and, from that, making necessary changes to the processes.

The aviation world has been well ahead of the pack when it comes to tracking and isolating root causes for faults on the aircraft itself. There are many commonalities between the setup of ATAs, zones or systems and the regular measurement of faults for each category. There is also a need for reactive and proactive actions in the aviation world; for instance, the grouping of IT components into units on which a service is dependent and the regular monitoring of these components. In reality, it’s the same idea behind each development with the difference that IT Services companies have been running a little bit faster lately and are now some way ahead when it comes to a total business process orientated organisation.

Benefits

So, you might ask, what is the real benefit for airline businesses from taking this structured approach? Well, our operations are governed by regulatory authorities and there are numerous rules and regulations to follow. Many of these are kept in the Continuing Airworthiness Management Organisation Exposition (CAMOE) and the real benefit comes when you incorporate the business processes (BPs) into your steering document. By doing so, you automatically set your review/update schedule to the same as the document, thus ensuring that your processes are reviewed and updated on a regular basis, which is vital if they are to remain relevant and are to continue to add value to the business.

However, that’s really the secondary benefit; the prime benefit is that, by incorporating the BPs into your IT system, you will minimize the risk of anything getting caught in between different departments, causing time slacks and triggering time consuming non routine actions. Technical departments in the aviation world are still very much divided into logistics, engineering, planning, production and quality assurance (QA). With help from BPs, you can retain those departmental names, but the core processes will flow right through them all with one hand-over point instead of maybe four or five as it is today. With help from BPs you’ll be able to create a visual document and one that is more understandable than just a written document such as the CAMOE itself; more understandable inasmuch as bottlenecks and areas for improvement will be more visible. You’ll also know exactly what to expect as an input and what is required as an output.

A sole MRO operator would see the benefit by always being able to control maintenance work according to the agreement that has been made with the customer: this being the basic framework for what is accepted and agreed will happen during the maintenance event, leading to faster invoicing for performed work and better financial management for both parties.

In short, you should visualise your way of working to gain:

– A common holistic view;

– More efficient workflows;

– Quality assured products and services.

Visualisation – the key

Visualisation is one of the key elements for organisations, allowing individual resources to ‘see’ their part in the full process and hence gain a better understanding of the workflows. Processes are visual and should be easy to understand on a graphical level, while, of course, still thoroughly explained and structured on a documentary level.

A business process project in detail

Considerations

It’s important to have the prerequisites in place before even starting to think about business processes. You’ll need a proper and accurate understanding of the company’s process maturity, management focus (plus willingness to sponsor the project with time and resources), availability of key personnel, availability of time and communication methods. Communication is a critical part of this project from the start, so put some extra time into the definitions before the project starts.

Definitions

What is a process?

– Initiated by an event, a process is a collection of activities that together create a result leading to an increased value for the customer.

Who is the customer?

– The receiver(s) of the results of the process;

– The customer of the customer – the end user;

– Note: there are external and internal customers and processes.

What are the success factors?

– Design (how to realize the end result);

– Performers (personnel who drive and operate the process with their knowledge, etc.);

– Owners (personnel responsible for the process and its results);

– Infrastructure (information and management system that support the process);

– Measurements (to evaluate the performance of the process).

Commencing the project

Commence your modelling by asking these questions:

– What is our purpose?

– What are our targets and vision and what will be the effects of the process?

– Is there commitment in the business?

– Do we have the organisation’s approval?

– Who should be kept informed of progress and have we planned the necessary communications?

… and when the questions have been answered…

– Establish a project (with specified deliveries, risk analyses, etc.).

Start mapping the job

– Brainstorming;

– Devise a process map;

– Produce a detailed ‘customer’ analysis;

– Establish what value(s) there will be for customers;

– Establish priorities;

– Agree and establish key performance indicators (KPIs);

– Name the process – remember to name it correctly so that it can be easily recognizable.

Figure 3

Today-tomorrow view – planning ahead

– Model in detail to predict how things will proceed;

– Establish methods for measuring actual time, cost and quality achieved;

Future processes

– Agree, establish and record future processes;

– Identify and quantify elements of risk.

Introduce the results of the project…

– The new standards of competence;

– The process to all departments and locations;

– Generate, produce and introduce checklists;

– Understand and take account of abbreviations and acronyms;

– Communicate to those affected by it or who have to operate it, the organisation, roles and responsibilities in the process;

– Ensure full IT support.

Establish the system

– Test the process;

– Confirm resource allocation;

– Hand over the process to user departments.

Living with processes

– Constantly improve the process in the light of experience.

Methodology

There are numerous methods for process modelling. I’ve been using IRM (Information Resource Management) and the templates shown are examples of their setup of documents that control the creation and description of the processes.

A process will never be better than the first detailed information resulting from the initial brainstorming, establishment of today-tomorrow processes and the acceptance of these. One person alone cannot create a process for the organization, the entire organization within the scope of the process must do this together in order to establish their ownership of the process, otherwise the result will most likely just be a paper product and totally worthless for the company. See process modelling as a new start for the organisation and as a large team effort that will lead to better performance and quality assured workflows; adding value to your company through better serving your internal and external customers.

Example

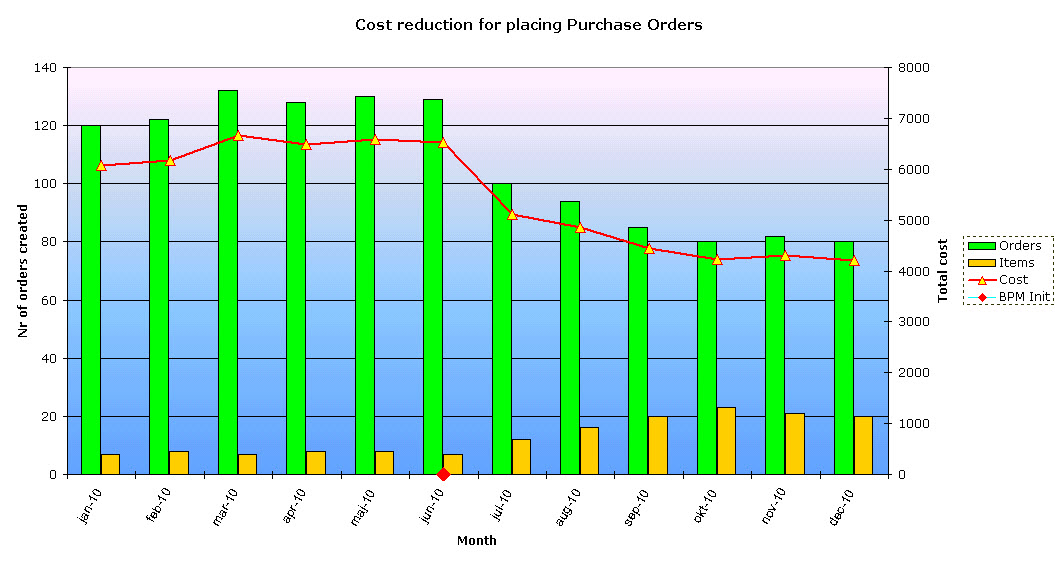

Monitoring Purchase Orders by measuring the total number of orders vs. the number of order lines for each order during 2010

Let’s assume that the purchasing process has a KPI to measure the number of orders issued in a specified period (last full year). Let your MRO IT system calculate the actual number of created orders (all PO’s) including a measurement for each order that displays the average number of order lines included in each order. Let it also compare the pricelists and capability lists from each vendor or supplier in order to find out if it might be less costly to purchase more parts from one vendor at the same time as other purchases or whether, by increasing the potential number of lines ordered from a vendor, you can negotiate a better price on all the lines in question.

KPI’s:

– Number of PO’s;

– Number of order lines.

Comparison:

– More parts numbers (PNs) available for purchase at fewer vendors? (more efficient use of contracts).

Fixed values:

– Cost for creating order: EUR 50

– Cost for order line: EUR 10

With this analysis you’ll be able see that you can purchase more part numbers from fewer vendors or suppliers. Putting a cost for each order including the cost for each line will let you be able to measure before and after values.

This is just a very small example of an activity within the purchasing process that uses KPI’s to visualise the development during a specified time. It’s important to include the milestones for changes in the processes so that you can measure if the performed actions also lead to the expected result or not. If not, determine why, define the scope of the work and perform new actions.

Comments (0)

There are currently no comments about this article.

To post a comment, please login or subscribe.